Concentrating and drying equipment for producing L-prolinamide

A technology for concentrating drying and prolineamide, which is applied in separation methods, climate sustainability, chemical instruments and methods, etc., can solve the problems of low processing efficiency and poor drying temperature control accuracy, and achieves improved heating uniformity and rapid heating. Concentration, the effect of improving the efficiency of heating and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

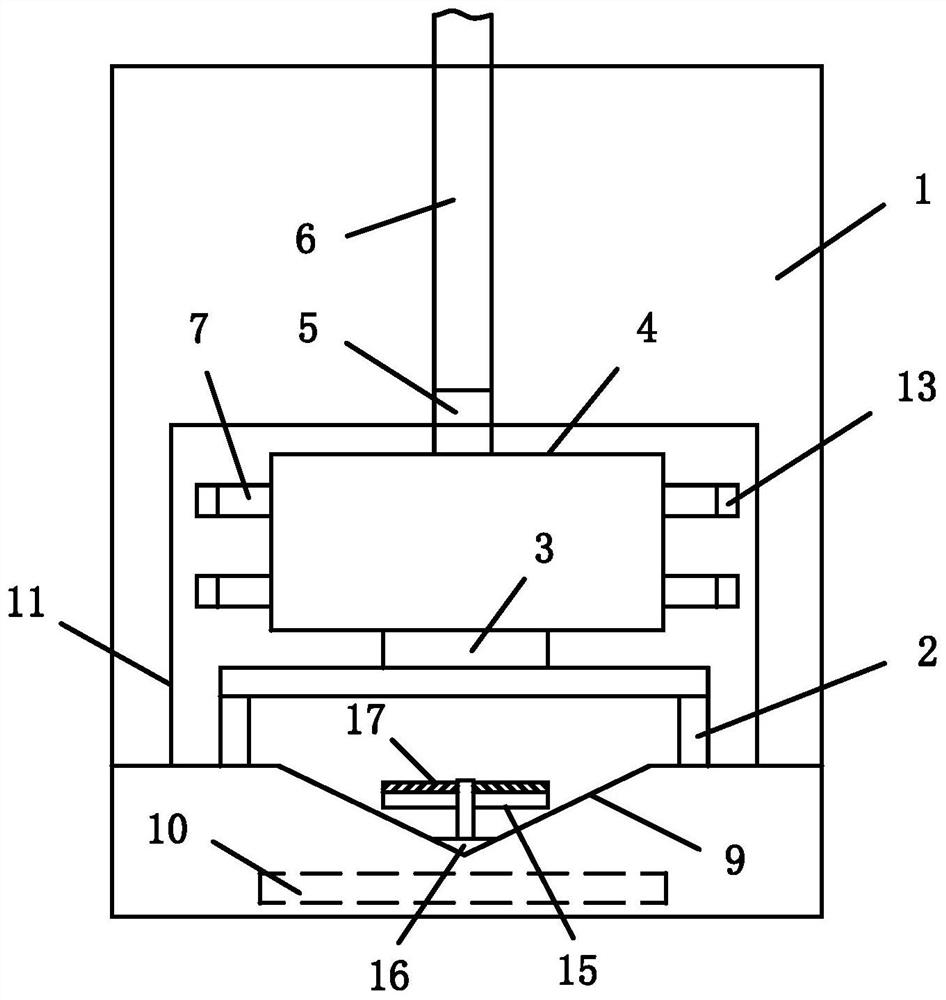

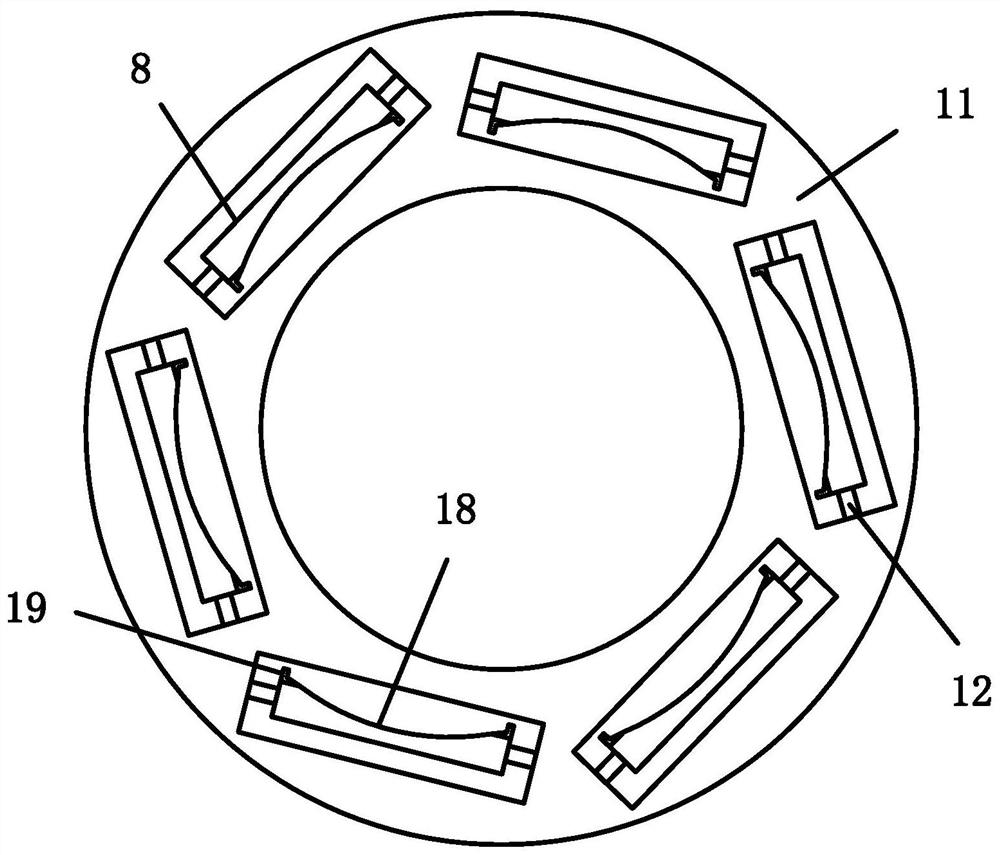

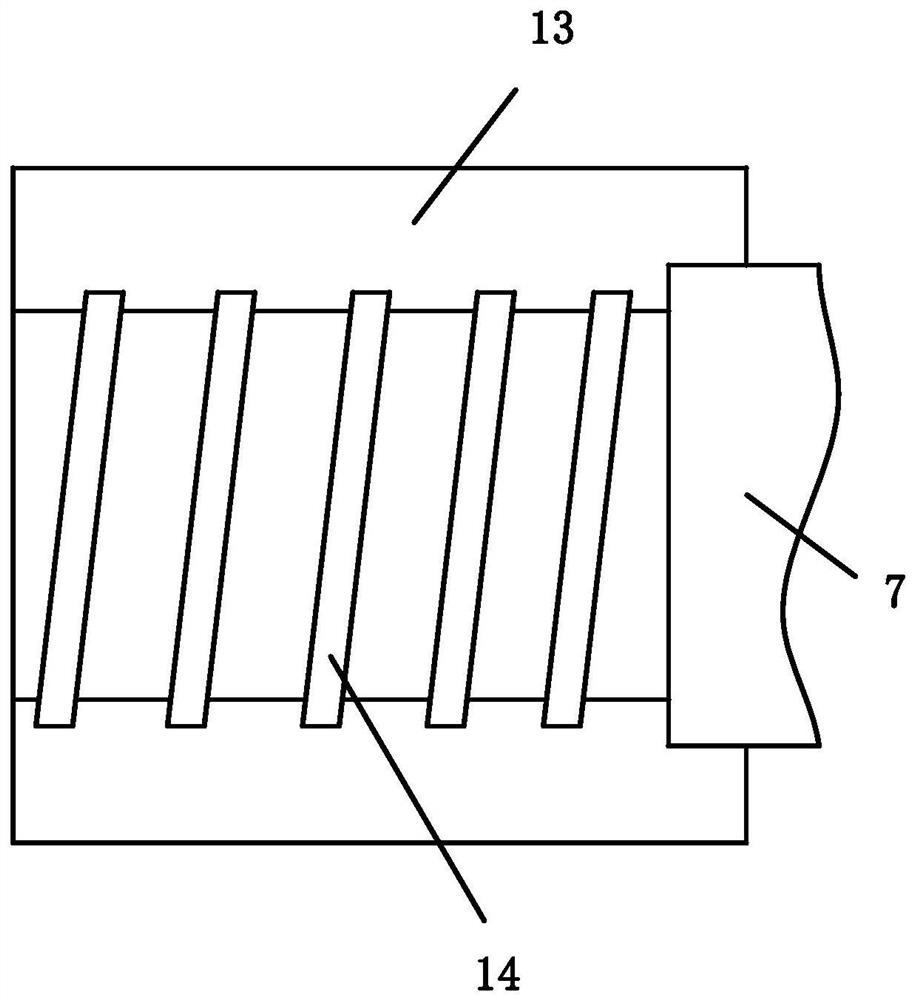

[0016] refer to Figure 1-3 , a specific embodiment of the present invention includes a tank body 1, a drive motor 3 is installed on the bottom of the tank body 1 through a bracket 2, a cavity 4 is connected to the output shaft of the drive motor 3, and a cavity 4 is connected to the top of the cavity 4 through a rotary joint 5. The liquid pipe 6 and the side wall of the cavity 4 are provided with several liquid outlet pipes 7, and several baffles 8 are arranged circularly in the tank body 1, and the baffles 8 are located outside the cavity 4, and the tank located inside the baffle 8 A confluence tank 9 is arranged at the bottom of the body 1 , and a heater 10 is installed at the bottom of the tank body 1 . The bottom of the tank body 1 is fixed with a hollow slot 11, and the baffles 8 are plugged into the hollow slots 11. There is a gap between adjacent baffles 8, and the angle between the adjacent baffles 8 is 130°. A heat conducting sheet 12 is arranged in the hollow slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com