Simple method for detecting aperture ratio of foam metal with network-shaped through hole structure

A metal foam and detection method technology, applied in the direction of testing metal, testing metal structures, material inspection products, etc., can solve the problems of cumbersome and inconvenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

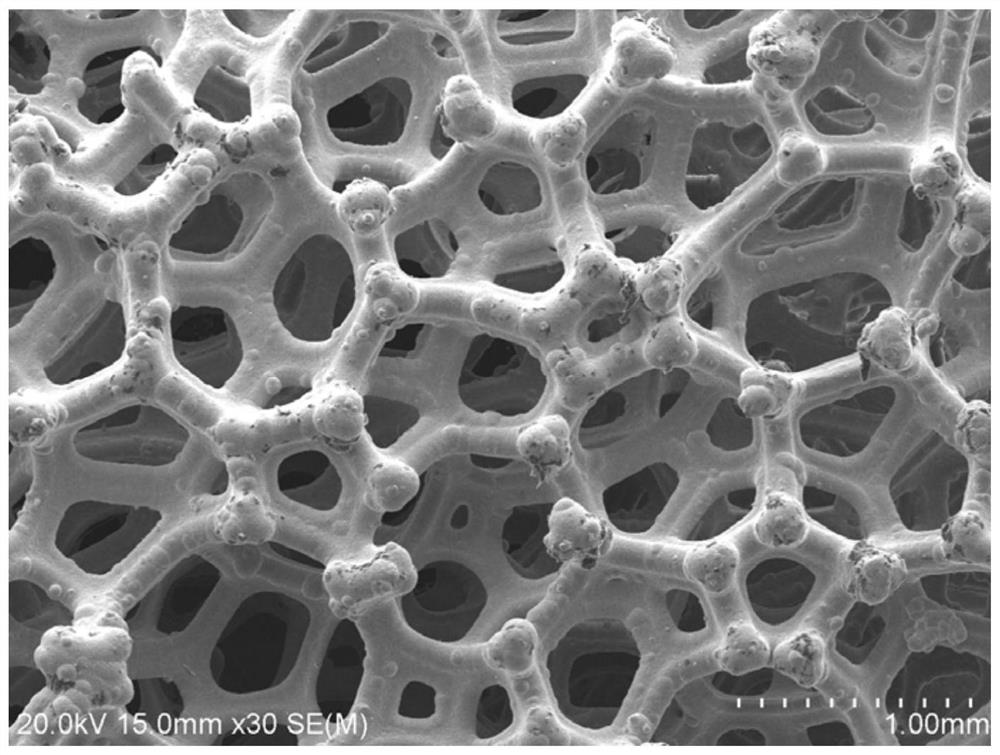

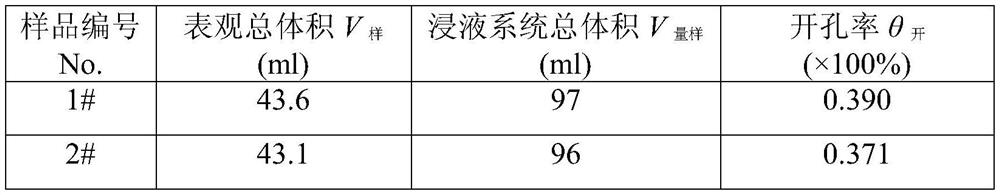

[0026] Embodiment: The sample to be tested is a nickel foam product produced by a certain enterprise, and its pore structure and morphology can be found in figure 1 . The size of the cut bulk sample is roughly 20cm×20cm×5.5mm, and the rough measurement of its pore size is below 1mm. In order to obtain more comprehensive statistical data, 4 small samples with a size of about 50mm×40mm×5.5mm were cut from 4 different parts of the sheet to be inspected. Clean the sample successively with acetone ultrasonic cleaning, clean water ultrasonic cleaning, and alcohol ultrasonic cleaning for 10 minutes each, and put them together into a volume scale of 0.5ml (that is, 0.5cm 3 ) in a clean measuring cup. Pour 80ml of deionized water into the graduated cylinder, ensuring that there is a sufficient level of liquid above the sample while submerging all the samples. Then place it in a cold water bath for 10 minutes of ultrasonic vibration, and deionized water is fully immersed in the open ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap