Drilling machine facilitating drill bit installation

A drilling machine and drill bit technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, positioning devices, etc., can solve problems such as complicated procedures, and achieve the effect of reducing installation technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

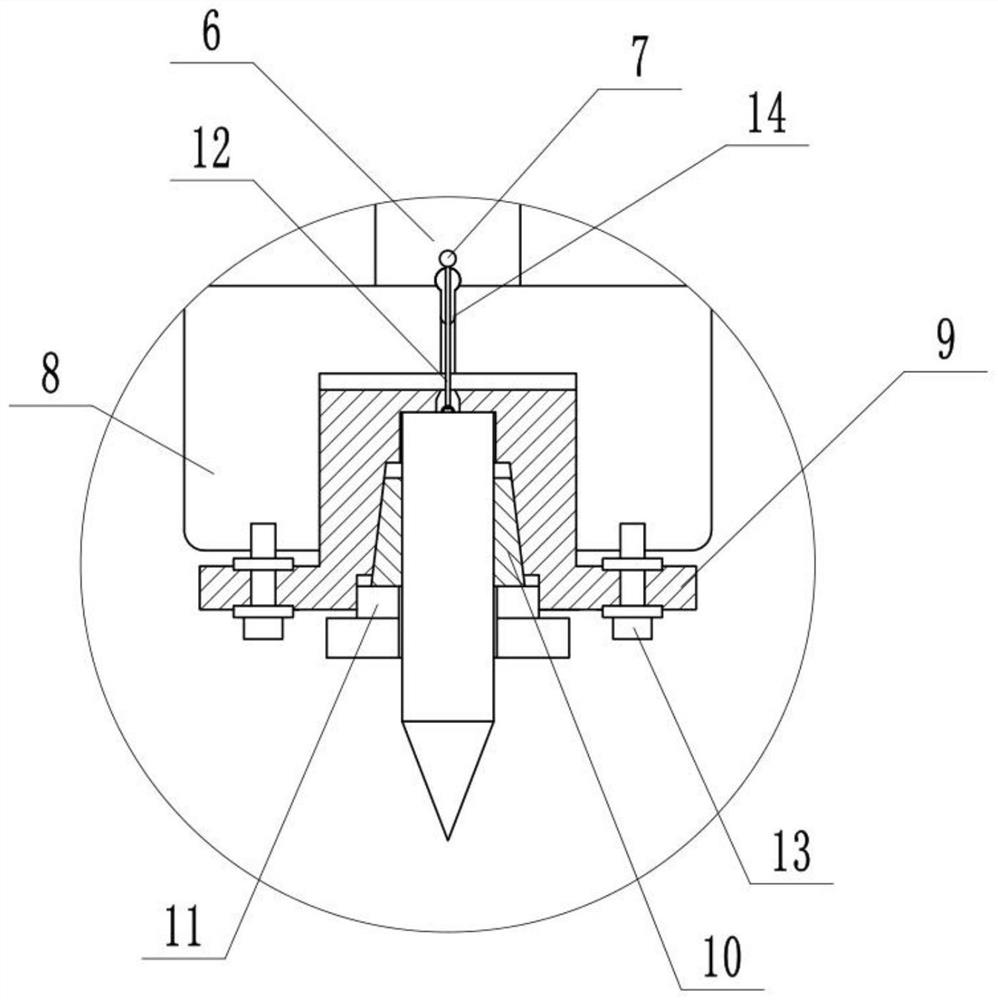

[0019] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

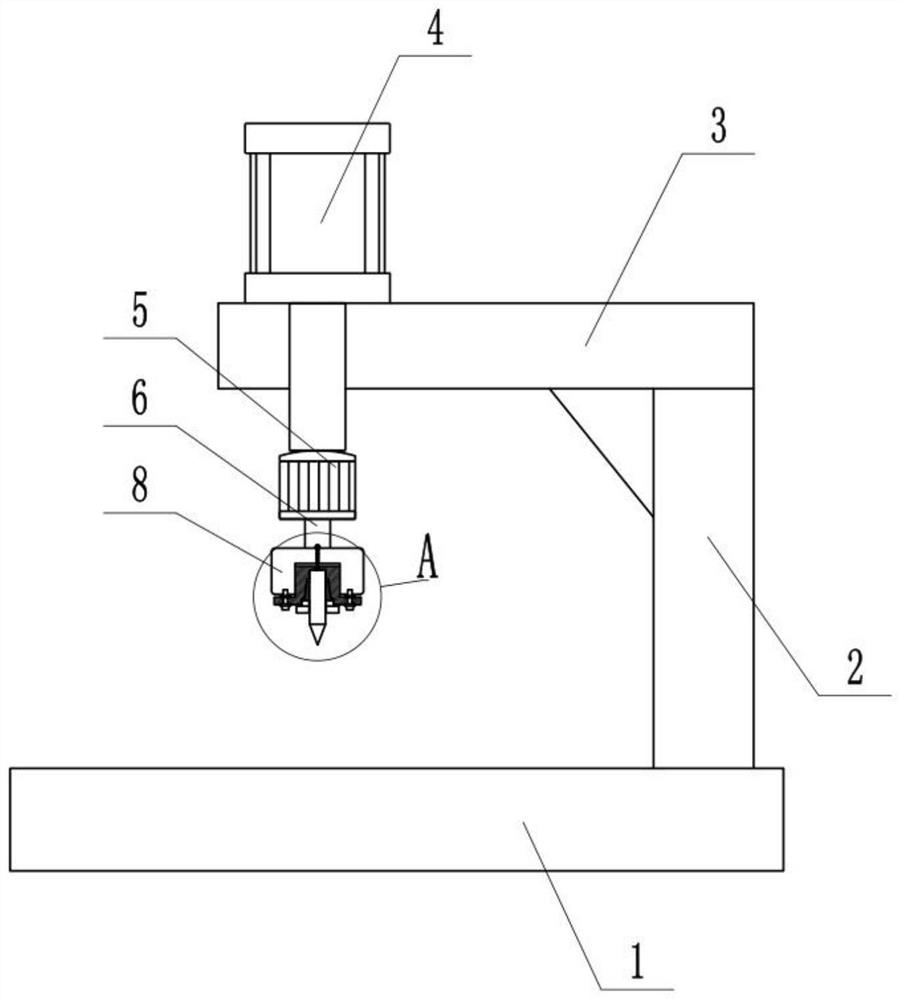

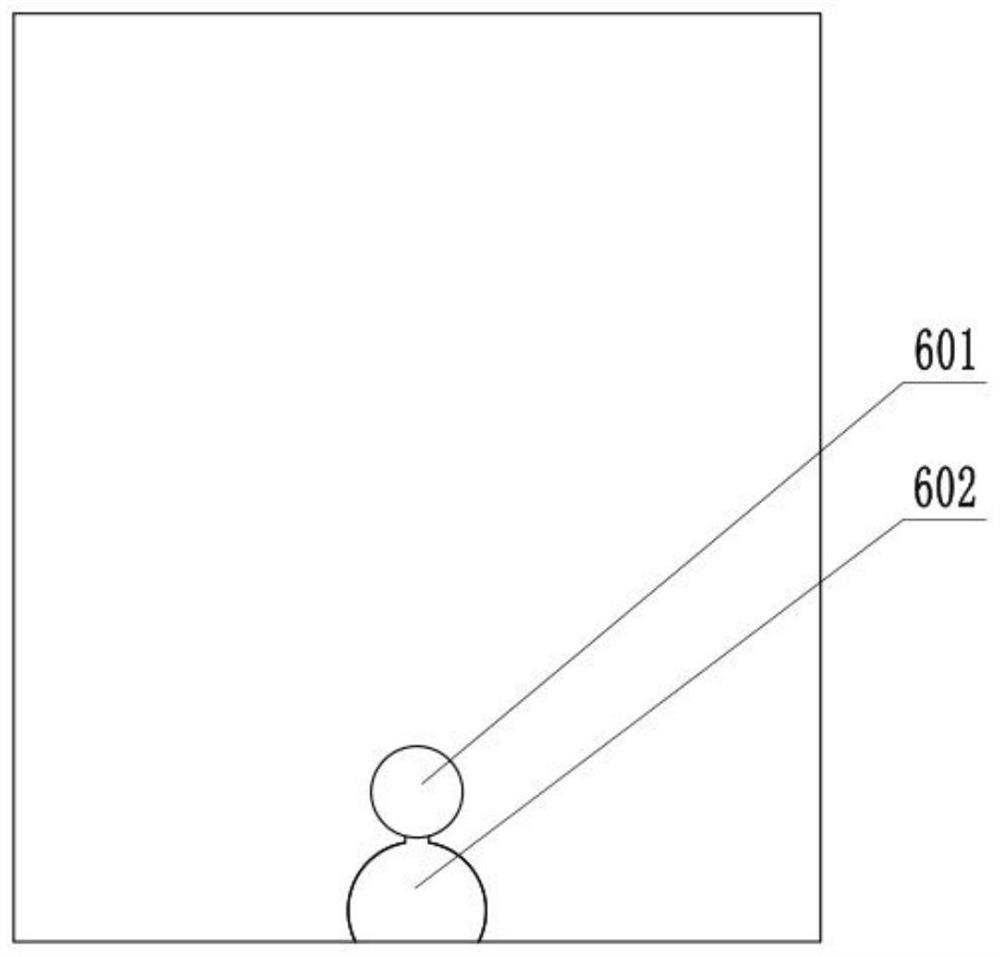

[0020] A drilling machine that facilitates the installation of drill bits such as Figure 1 to Figure 5 As shown, it includes base 1, supporting column 2, top plate 3, hydraulic cylinder 4, rotating motor 5, connecting plate 6, locking screw 7, mounting plate 8, clamping block 9, inclined block 10, locking block 11, positioning rope 12 and adjusting screw 13.

[0021] The support column 2 is arranged on the base 1, and the top plate 3 is fixedly arranged on the support column 2. Preferably, the top of the left side of the support column 2 is fixedly connected with a reinforcing rib, and the top of the reinforcing rib is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com