Small hole well completion lifting technology tubular column and use method thereof

A technology for process pipe strings and wellbore, which is applied in the field of tools, can solve the problems of lifting pipe strings and inconvenient positioning, and achieve the effect of simple structure, easy operation, and reduced control structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

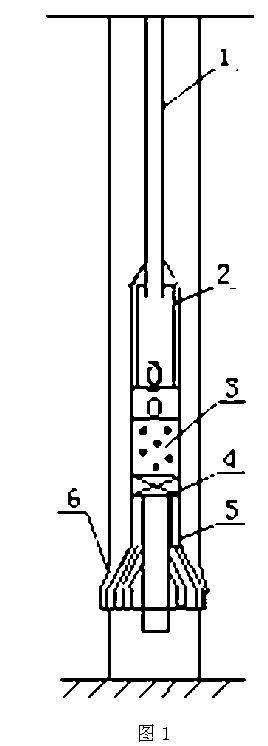

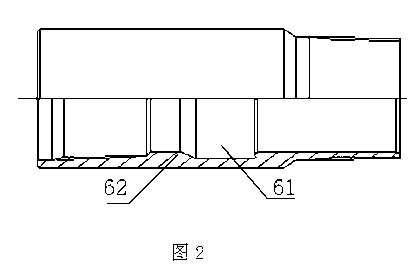

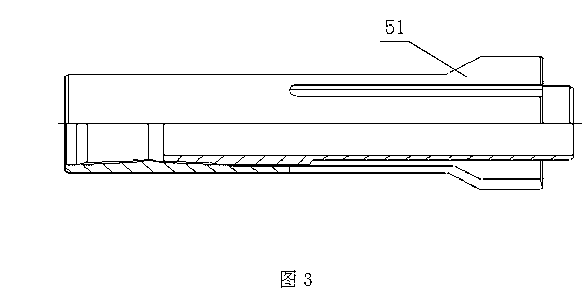

[0043] Such as figure 1 , figure 2 , image 3 The shown slim hole completion lifting string assembly includes a hollow oil rod 1, a rod pump 2, an anchor 5 and a lifting mandrel equipped with a mechanism that cooperates with the anchoring mechanism of the anchor 6. The anchor is an anchor lock sleeve 5, and the anchor lock sleeve 5 is provided with a split lock pawl 51, and the anchor of the lifting cylinder 6 and the anchor is The matching mechanism of the fixed mechanism is the reaming 61 matched with the split lock claw 51 of the anchor lock sleeve 5, and the lower end of the reaming 61 of the lifting working cylinder is provided with a supporting boss 62. A screen pipe 3 and a plug 4 are arranged below the rod pump.

[0044] The method of use is as follows: when completing the well, follow the steps in sequence: (1) Lower the lifting mandrel 6 to the casing position corresponding to the depth where the rod pump 2 should hang; (2) The hollow oil rod 1, the rod pump 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com