Aluminum frame plastic formwork for building

A technology for plastic formwork and construction, which is applied in construction, on-site preparation of building components, and building construction. The effect of stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

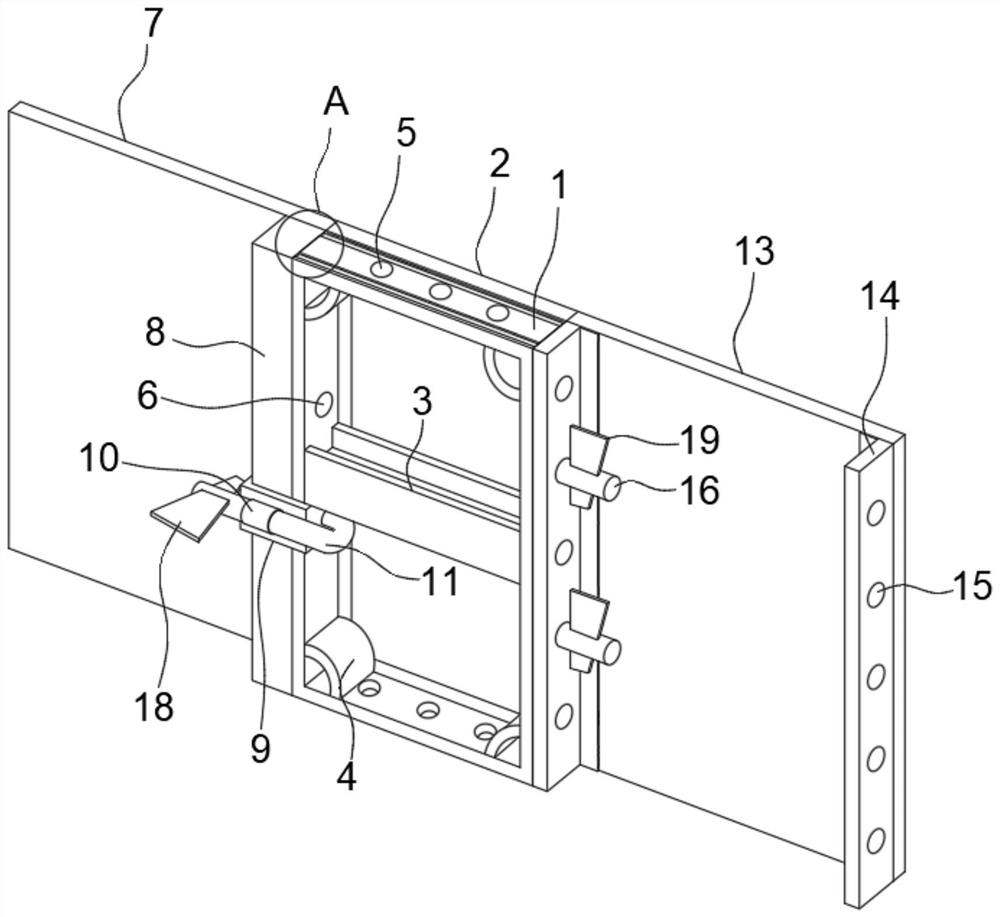

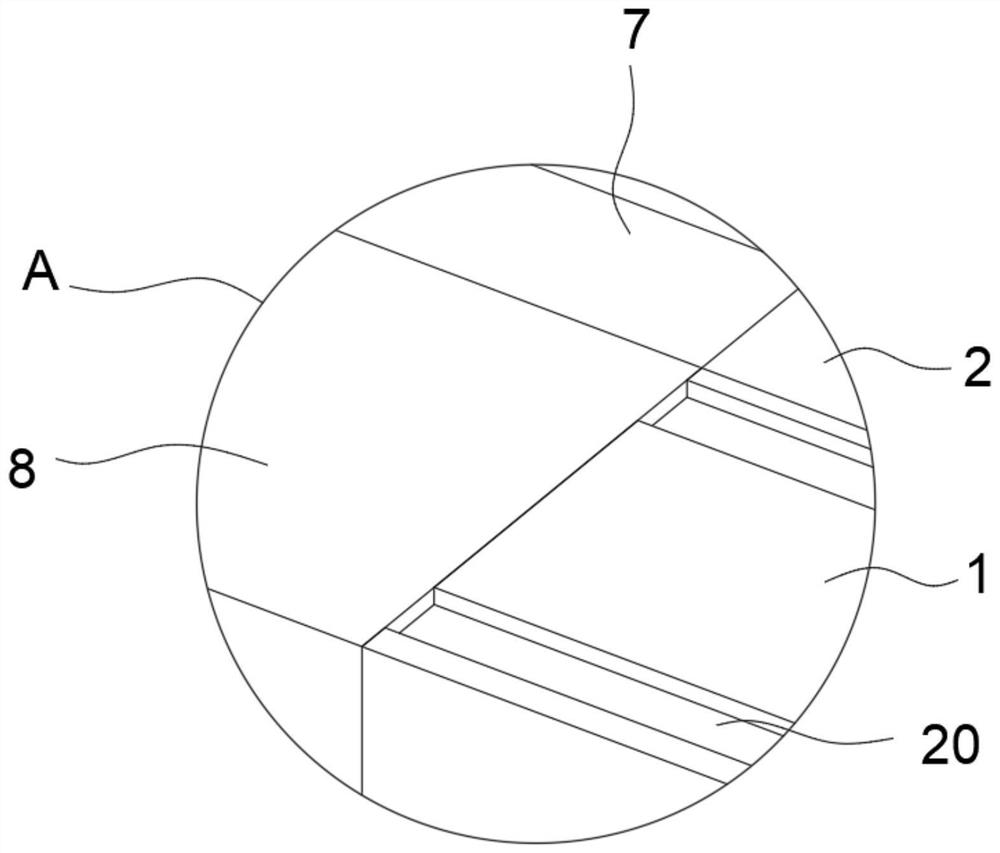

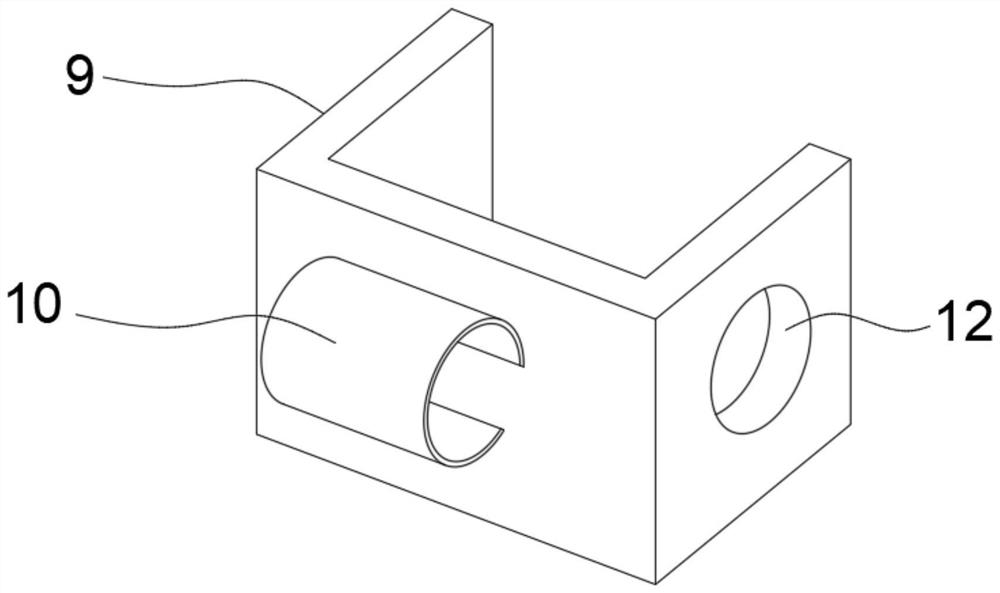

[0025] refer to Figure 1-4 , a plastic formwork with aluminum frame for construction, including a rectangular aluminum frame 1, the aluminum frame 1 is made of aluminum alloy material, its quality is lighter than that of steel material, and its strength and stability are better than that of wooden material Higher, there is a first plastic formwork 2 on the rear side of the aluminum frame 1, so that the first plastic formwork 2 can be firmly connected with the aluminum frame 1, so as to improve the durability of the first plastic formwork 2, the aluminum frame 1 is about The center positions of the inner walls on both sides are jointly fixed and welded with a central cross brace 3 with an I-shaped cross section. The central cross beam 3 greatly improves the structural strength of the aluminum frame 1 and makes the structure more stable. The I-shaped structure does not reduce the support strength. The adjustment greatly saves materials. The four inner corners of the aluminum fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com