Automatic locking mechanism for special vehicle doors and windows

A technology for automatic locking and special vehicles, applied in vehicle locks, electric locks, building locks, etc., to achieve the effects of compact structure, reduced frictional resistance, and reliable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

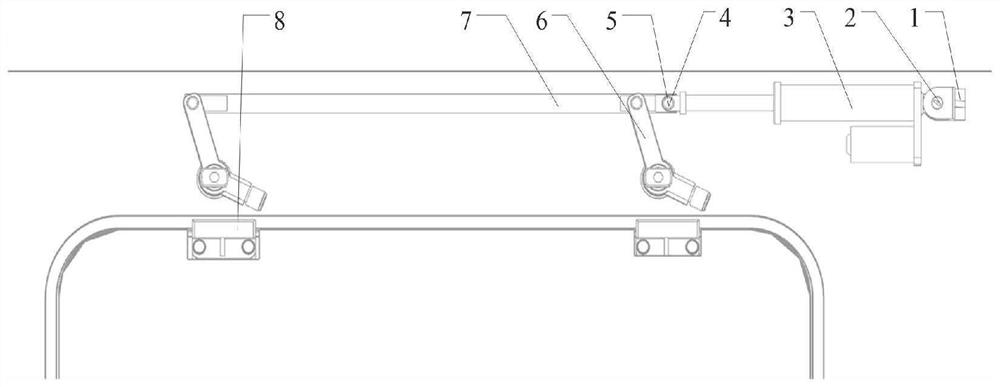

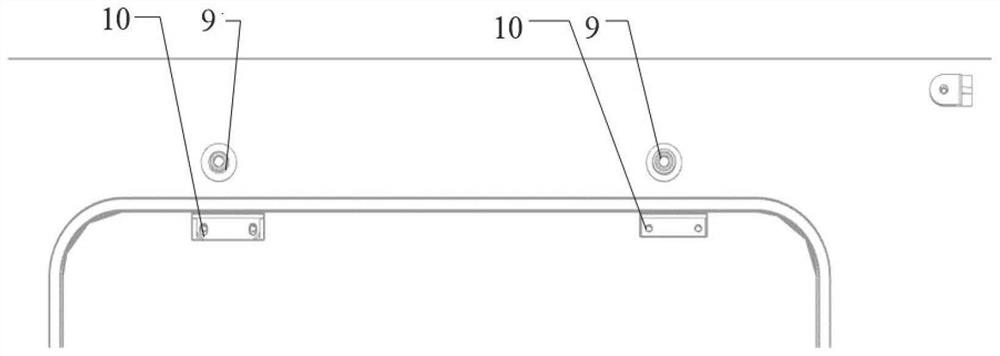

[0033] This embodiment proposes an automatic locking mechanism for doors and windows of special vehicles, its structure is as follows: figure 1 and 2 As shown, it mainly includes electric cylinder support 1, electric cylinder pin 2, electric cylinder 3, connecting rod pin 4, cotter pin 5, rotating arm assembly 6, connecting rod 7, locking mechanism assembly 8, rotating arm Support 9 and locking base 10.

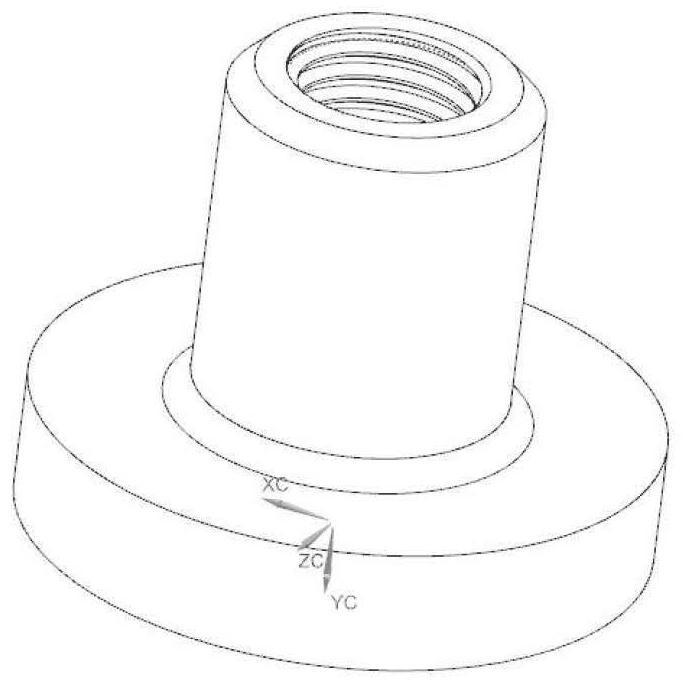

[0034] Electric cylinder support 1 and two boom supports 9 (such as image 3 shown) welded at the set position on the top deck of the door frame, and the two locking bases 10 are respectively welded to the set position on the door panel, and ensure the centerlines of the two pivoting arm supports 9 and the centerline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com