Hydraulic claw hand tool for preventing drill jamming and blockage

A hand tool and hydraulic claw technology, which is applied in the field of hydraulic claw hand tools to prevent sticking and clogging, and achieves the effects of speeding up the throwing speed, saving costs, and increasing the force-bearing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

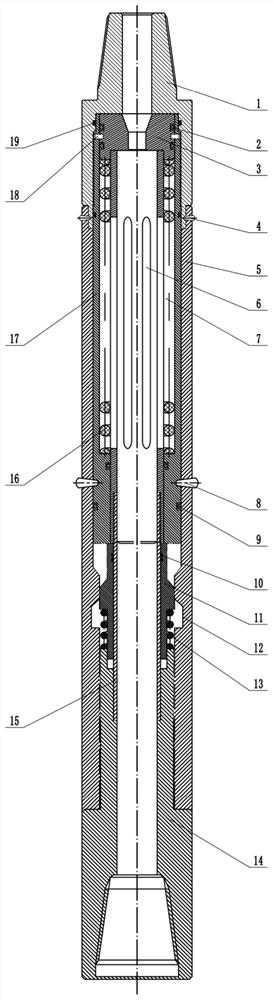

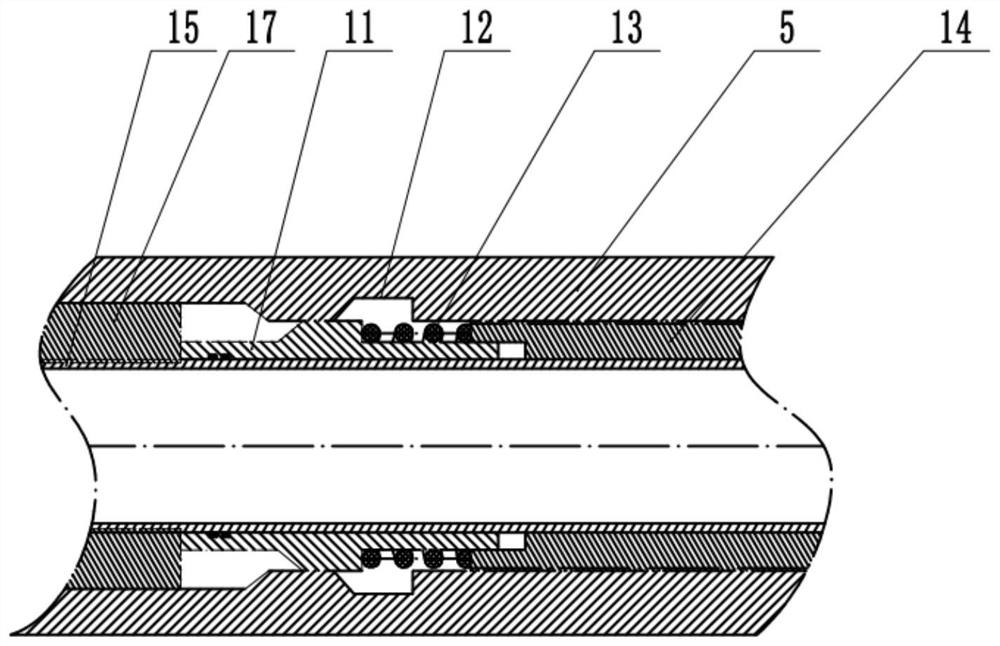

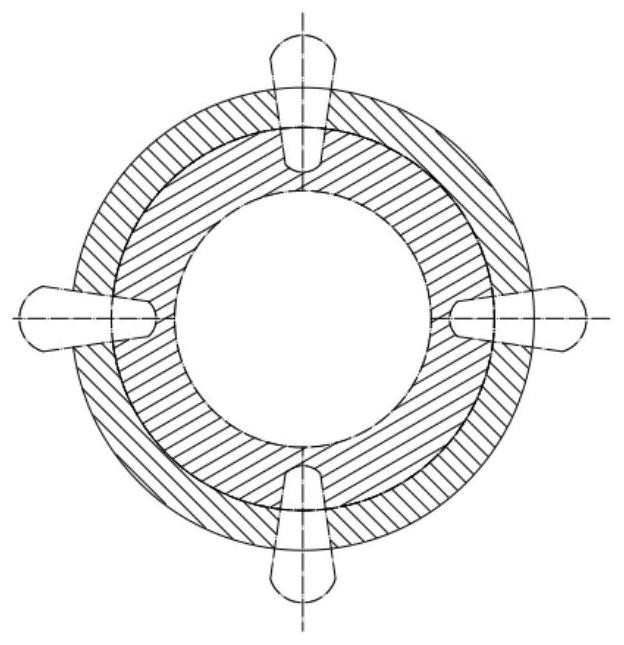

[0013] Such as Figure 1-3 As shown, the tool is a hydraulic gripper tool that prevents drill sticking and blockage. Its structure mainly includes a lower joint 1, an outer cylinder 5, an inner cylinder I15, an upper joint 14, an inner cylinder II17, an elastic gripper 11, Claw grip slot 12, pressure spring 13, piston 3, pin I4, pin II8, spring 16, countersunk screw 18, sealing ring I19, sealing ring II2, sealing ring III9, sealing ring IV10, piston chamber 6, spring chamber Chamber 7; its structural features are: the lower joint 1 cooperates with the outer cylinder 5, the pin I4 is installed at the joint between the lower joint 1 and the outer cylinder 5, the inner cylinder II17 and the piston 3 are connected by countersunk screws 18, and the inner cylinder II17 Installed on the outside of the spring chamber 7 and sealed by two sealing rings I19 and two sealing rings III9, the piston 3 is installed on the inner wall of the inner cylinder II17 and sealed by two sealing rings I...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap