A horizontal support installation device and support installation method for the back of marine equipment

A technology of horizontal support and installation device, which is applied in the direction of hull parts, mechanical equipment, auxiliary equipment, etc. It can solve the problems of destroying the fire protection integrity of cabin panels, and achieve the effects of ensuring fire protection integrity, eliminating installation errors, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

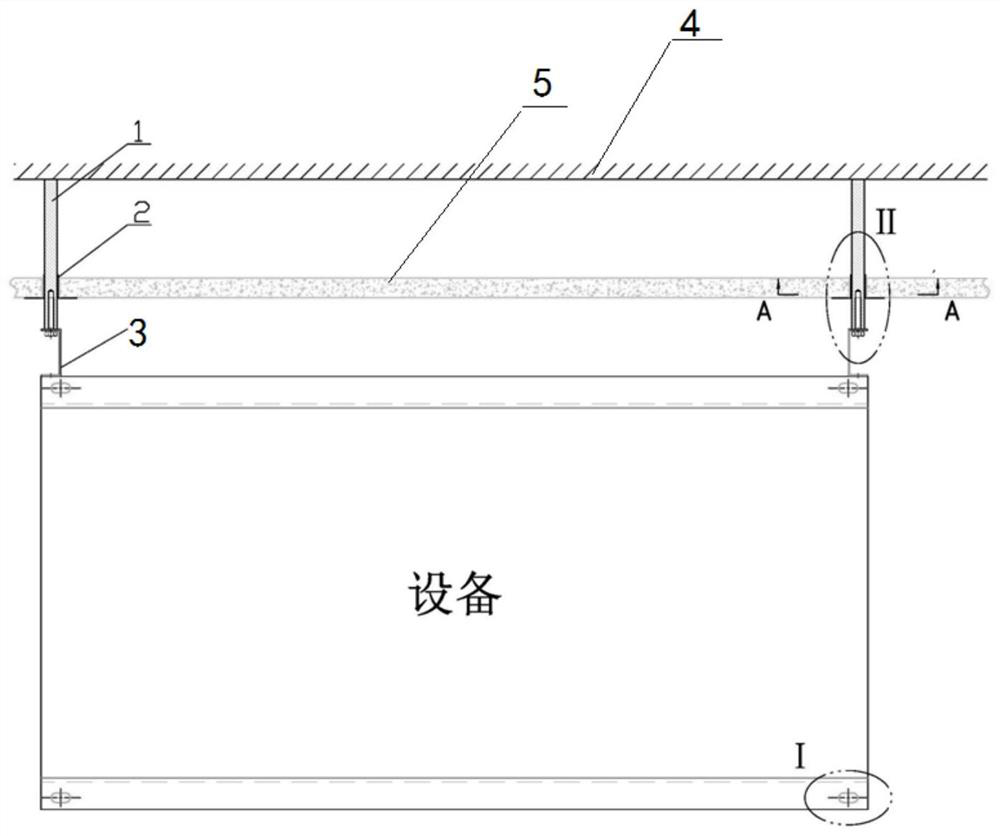

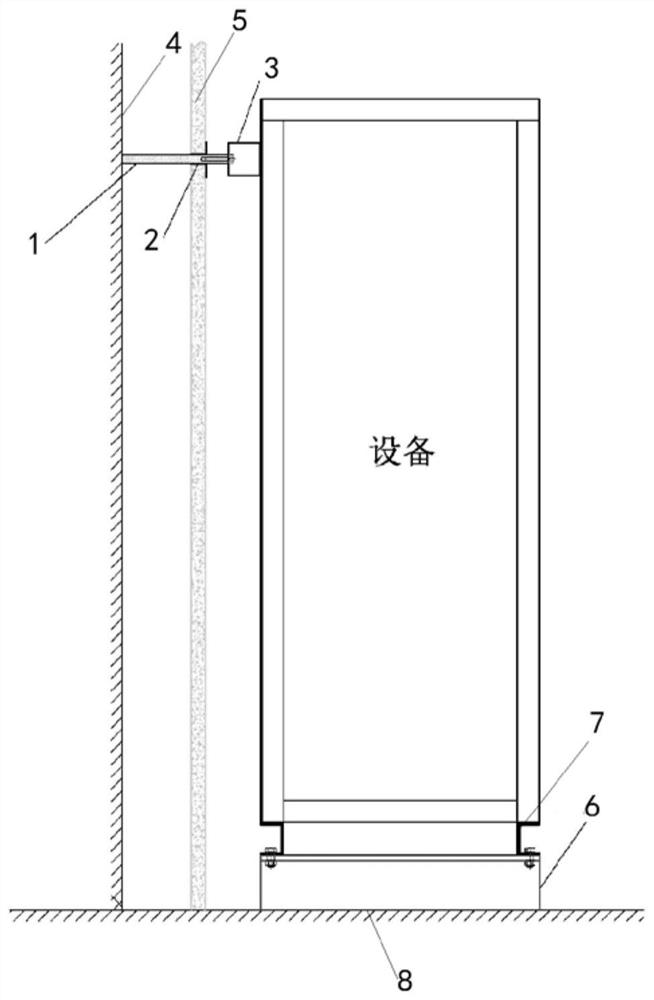

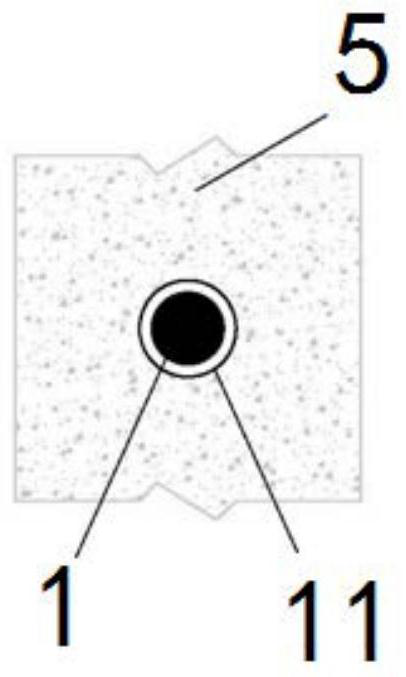

[0034] This embodiment provides a horizontal support installation device for the back of marine equipment, including an equipment base 6, a bottom support channel steel 7, a back support channel steel 3 and a horizontal support round steel 1. The diameter of the horizontal support round steel 1 is 16 mm-20 mm mm. The bottom support channel steel 7 belongs to the equipment itself and is fixedly installed at the bottom of the equipment, the back support channel steel 3 belongs to the equipment itself and is fixedly installed on the back of the equipment, the equipment base 6 is fixedly installed on the steel deck 8, and the bottom support channel steel 7 and The side connected to the equipment base 6 is provided with a first waist round hole 10 along the length direction, the bottom support channel steel 7 and the equipment base 6 are fixed and installed by bottom bolts, and one end of the horizontal support round steel 1 is welded and installed on the steel surrounding wall 4 ,...

Embodiment 2

[0039] The present embodiment provides a method for installing a horizontal support on the back of marine equipment, comprising the following steps:

[0040]Step 1, in the segmentation stage, the equipment base 6 is welded on the steel deck 8, and the horizontal support round steel 1 is welded on the steel surrounding wall 4;

[0041] Step 2. In the regional stage, according to the position of the horizontal support round steel, open a through hole in the corresponding position of the cabin plate, and install the cabin plate;

[0042] Step 3. In the regional stage, install the equipment: install the bottom support channel steel 7 and the equipment base 6 of the equipment through the bottom bolts, and install the back support channel steel 3 and the horizontal support round steel 1 of the equipment through the back bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com