A kind of fire-resistant wood and its preparation method and application

A wood, flame-retardant technology, applied in the direction of wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of good dispersion and low density, achieve excellent fire resistance performance, increase barrier properties, and ensure the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

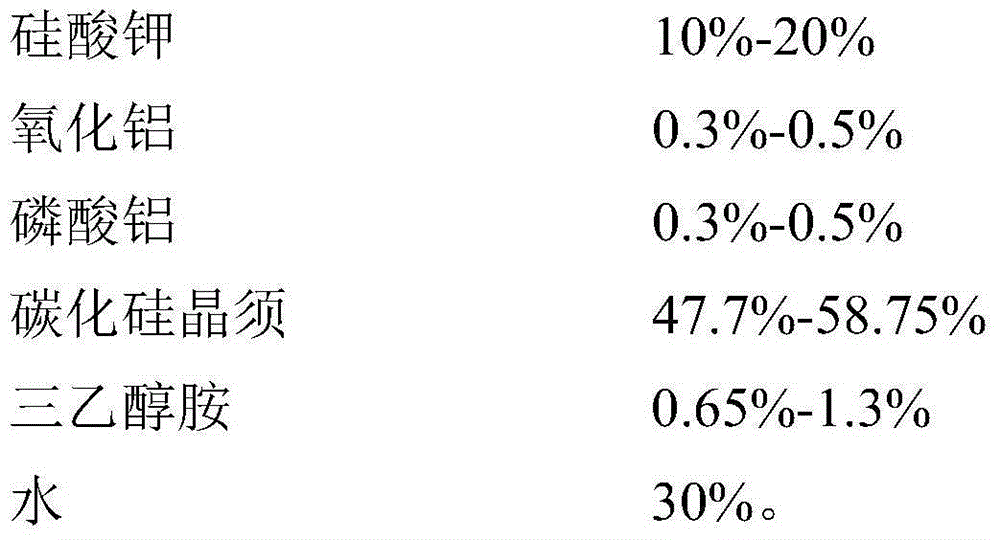

Embodiment 1

[0035] Put 35kg ammonium polyphosphate ((NH 4 ) (n+2) P n o (3n+1) , n=10) dissolved in 65kg of silica sol (SiO in silica sol 2 Dispersed in water in the form of micelles, SiO 2 The mass percentage is 25%), stirred at room temperature and evenly configured into flame retardant liquid A; 10kg of potassium silicate (modulus m=3.2), 0.65kg of triethanolamine, 58.75kg of silicon carbide whiskers (diameter 0.3μm, length 160μm) was added to 30kg of water, stirred at room temperature to form component 1, and component 2, a mixture of 0.3kg of alumina and 0.3kg of aluminum phosphate, was added to component 1, stirred and mixed at room temperature to make flame retardant suspension B. spare.

[0036] Dry the fir raw material at 65°C until the moisture content is not higher than 10%, then place it in the treatment tank and seal it, pump the treatment tank to a vacuum of 0.04MPa and keep it for 2 hours; inject flame retardant liquid A into the treatment tank under vacuum, Then pres...

Embodiment 2

[0038] Put 20kg ammonium polyphosphate ((NH 4 ) (n+2) P n o (3n+1) , n=20) dissolved in 80kg of silica sol (SiO in silica sol 2 Dispersed in water in the form of micelles, SiO 2 The mass percentage is 25%), stirred at room temperature and evenly configured into flame retardant liquid A; 10kg of potassium silicate (modulus m=3.2), 0.65kg of triethanolamine, 58.75kg of silicon carbide whiskers (diameter 0.3μm, length 160μm) was added to 30kg of water, stirred at room temperature to form component 1, and component 2, a mixture of 0.3kg of alumina and 0.3kg of aluminum phosphate, was added to component 1, stirred and mixed at room temperature to make flame retardant suspension B. spare.

[0039] Dry the fir raw material at 65°C until the moisture content is not higher than 10%, then place it in the treatment tank and seal it, pump the treatment tank to a vacuum of 0.04MPa and keep it for 2 hours; inject flame retardant liquid A into the treatment tank under vacuum, Then pres...

Embodiment 3

[0041] Put 40kg ammonium polyphosphate ((NH 4 ) (n+2) P n o (3n+1) , n=15) dissolved in 60kg of silica sol (SiO in silica sol 2 Dispersed in water in the form of micelles, SiO 2 The mass percentage is 25%), stirred at room temperature and evenly configured into flame retardant liquid A; 10kg of potassium silicate (modulus m=3.2), 0.65kg of triethanolamine, 58.75kg of silicon carbide whiskers (diameter 0.3μm, length 160μm) was added to 30kg of water, stirred at room temperature to form component 1, and component 2, a mixture of 0.3kg of alumina and 0.3kg of aluminum phosphate, was added to component 1, stirred and mixed at room temperature to make flame retardant suspension B. spare.

[0042] Dry the fir raw material at 65°C until the moisture content is not higher than 10%, then place it in the treatment tank and seal it, and the treatment tank is pumped to a vacuum of 0.02MPa and kept for 2 hours; inject flame retardant liquid A into the treatment tank under vacuum, The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com