Special camera for three-dimensional gear measurement center and measurement method

A gear measurement and camera technology, applied in the field of measuring tools and cutting tools, can solve problems such as inconvenience in observation, and achieve the effects of flexible and convenient use, convenient use and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

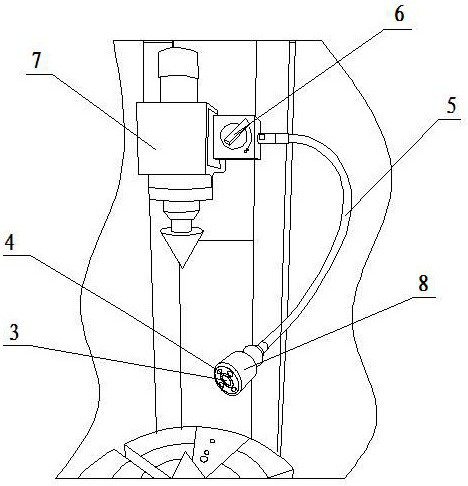

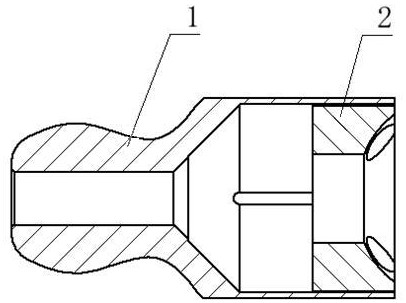

[0022] A special camera for a three-dimensional gear measurement center, which consists of: a camera cover body 8, the camera cover body includes a camera cover 1, a camera head 3 is installed in the camera cover, and the camera cover is connected to the camera through a screw thread The outer cover cover 2 is connected, and the camera head is axially fixed. The camera outer cover cover has 4 holes, and LED lights 4 are respectively installed in the holes, and the camera head passes through the metal The serpentine tube 5 is connected with the PC end, and one end of the metal serpentine tube is connected with the camera cover, and the other end is connected with the magnetic gauge base 6 through a joint.

Embodiment 2

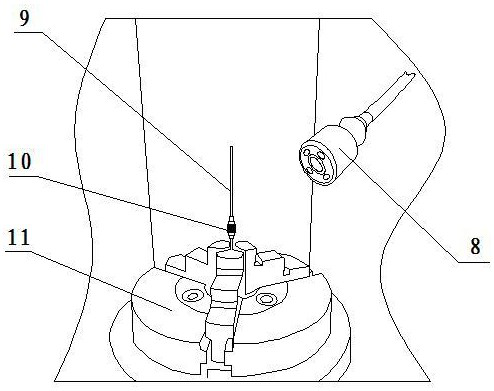

[0024] According to the special camera for the three-dimensional gear measurement center described in Embodiment 1, the magnetic table base is magnetically connected to the side plane of the top support arm 7 of the three-dimensional gear measurement center, and the three-jaw chuck 11 is fixed on the bottom of the three-dimensional gear measurement center On the plane, a mandrel 9 is fixed on the three-jaw chuck, and a workpiece 10 to be measured is sleeved on the mandrel.

Embodiment 3

[0026] A method for measuring a special camera for a three-dimensional gear measurement center, the method comprising the following steps:

[0027] First, the camera camera head is installed between the camera housing and the camera housing cover, and is jointly fixed by the camera housing and the camera housing cover. The camera housing cover has four holes, and is respectively installed in the four holes. LED light, the camera cover body is connected and fixed on the magnetic base by a metal serpentine tube, the camera head is connected to the PC end by USB, and the USB cable passes through the metal serpentine tube to connect to the PC end, and the workpiece to be measured is clamped in the 3D Between the upper and lower top of the gear measurement center, place the magnetic base on the upper top arm of the measurement center, turn the knob of the magnetic base to ensure that the magnetic base is firmly attached to the upper top arm of the measurement center;

[0028] Conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com