Safety helmet impact resistance puncture testing device

A test device and impact-resistant technology, which is applied in the direction of impact test, measuring device, machine/structural component test, etc., can solve the problem of incomplete test scenes of helmets, achieve perfect test scenes, improve integrity, open and store convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

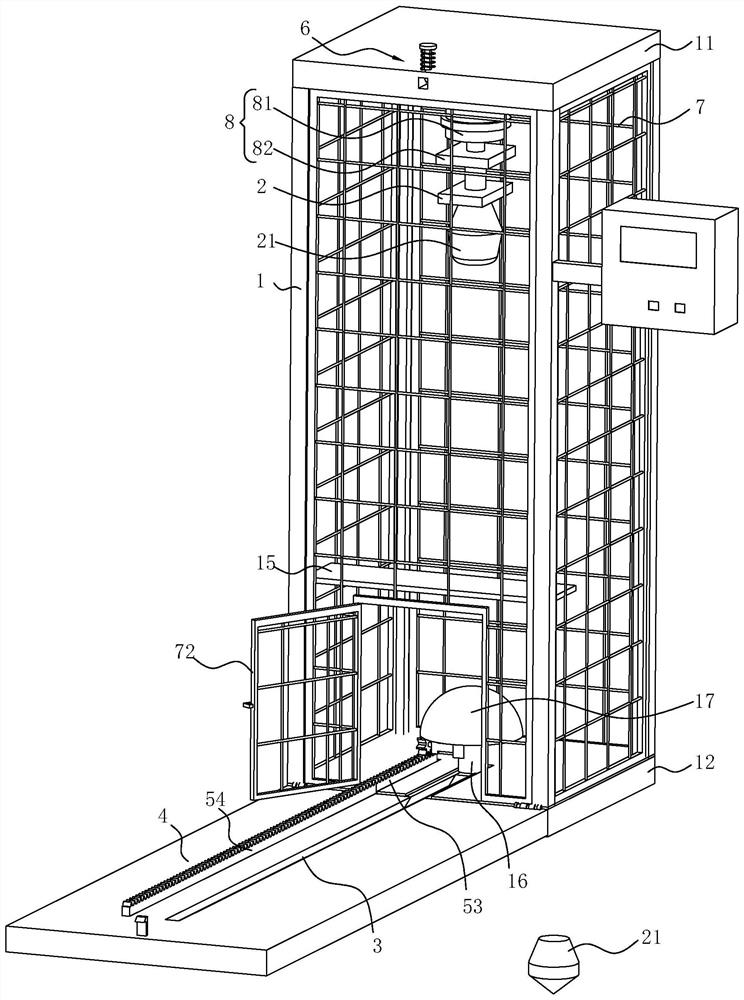

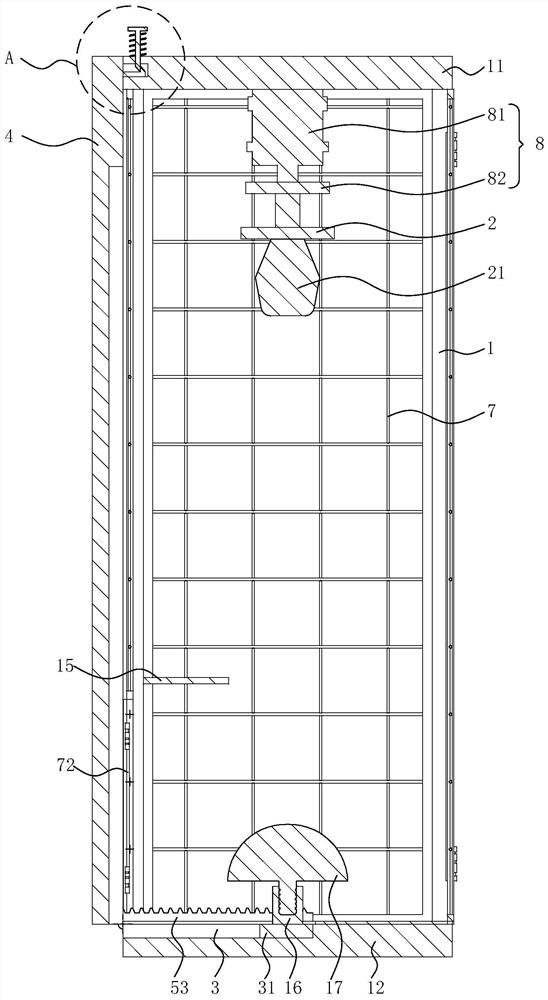

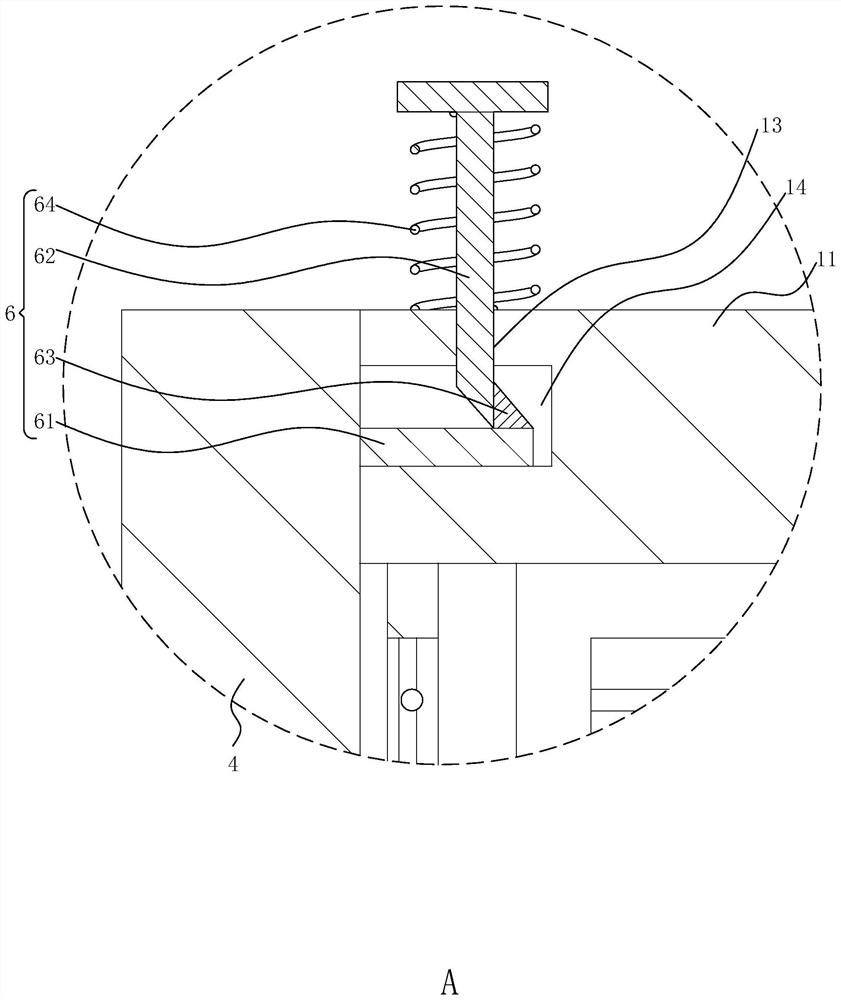

[0036] The following is attached Figure 1-4 The application is described in further detail.

[0037] The embodiment of the present application discloses a safety helmet impact puncture test device.

[0038] refer to figure 1 , a safety helmet impact resistance puncture test device includes a box frame 1, an electromagnet 2 is arranged on the box frame 1, an impact hammer 21 is adsorbed on the electromagnet 2, a mechanical sensor 16 is arranged in the box frame 1, and the mechanical sensor 16 is fixed A headform 17 is set, the helmet is fixed on the headform 17, the impact hammer 21 falls, hits the helmet, and the impact force is transmitted to the mechanical sensor 16, so as to obtain the impact data, which reaches the data for testing the impact resistance and puncture resistance of the helmet .

[0039] refer to figure 1, the box frame 1 is rectangular as a whole, the box frame 1 is vertically arranged, the top of the box frame 1 is fixedly provided with a cover plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com