Drill and insert for drill having improved centering capability and cutting performance

A technology for inserts and drill bits, used in drilling tool accessories, drilling/drilling equipment, components of boring machines/drilling machines, etc., to achieve the effects of minimized vibration, uniform performance, and excellent centering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

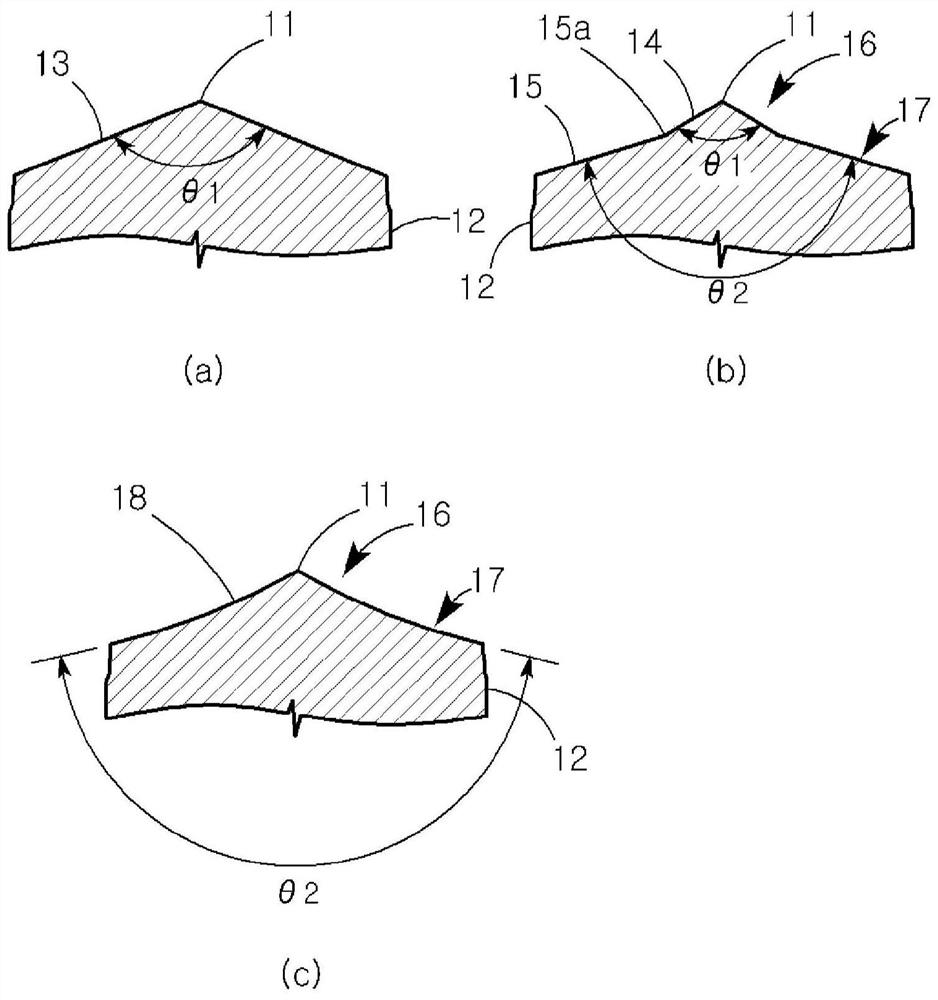

[0032] Hereinafter, the present invention will be described in more detail with reference to the drawings.

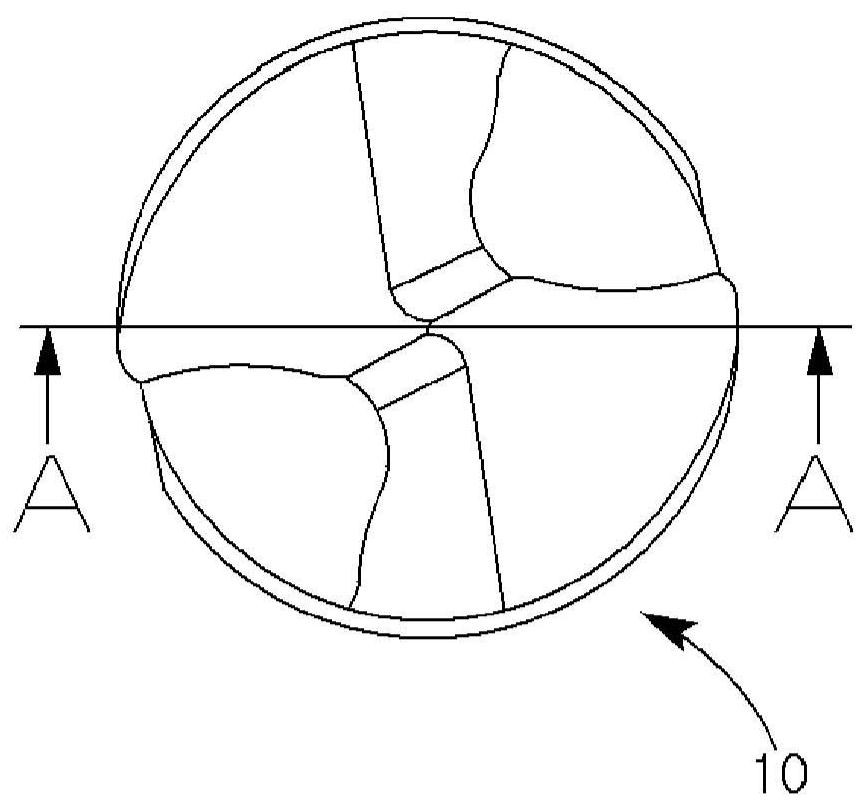

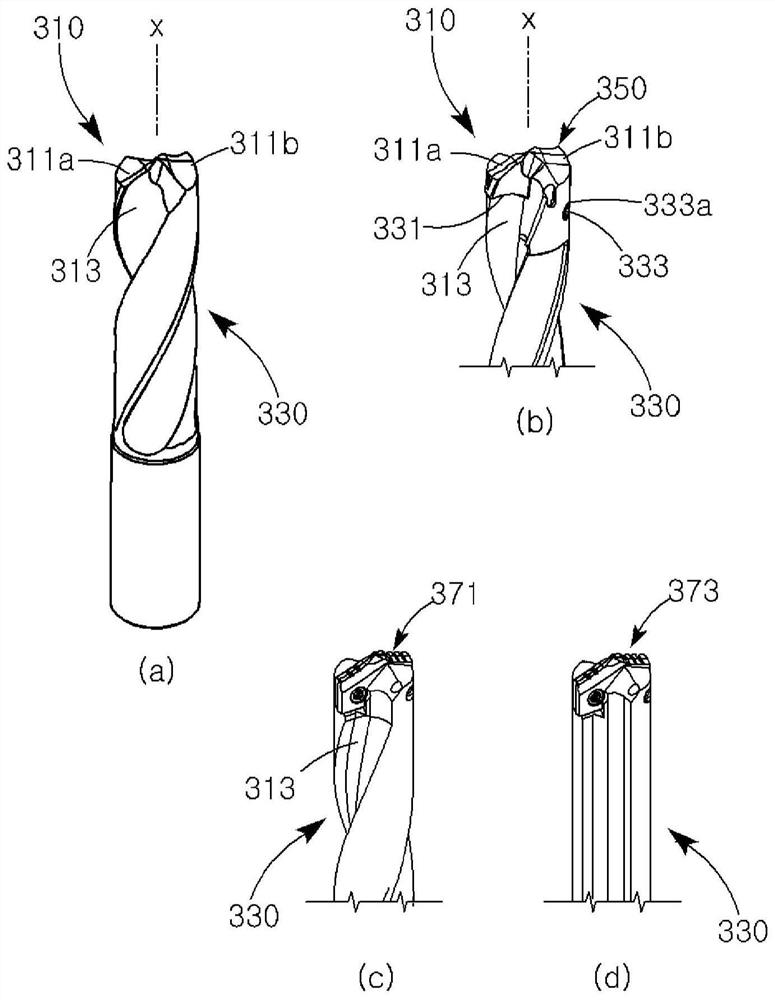

[0033] The present invention is not only applicable to common solid type (Solid type) drill bits, but also applicable to indexable type (Indexable type) drill bits. Inserts for indexable drills, such as spade drill inserts, also have various forms depending on the fastening method, and any of them can be applied. image 3 (a) shows an example of a common solid type (Solidtype) drill bit or a welding type drill bit, image 3 (b) shows an example of an indexable type drill, and image 3 (c) and (d) show examples of spade drills.

[0034] refer to image 3, The drill bit of the present invention includes a head 310 formed at the front end along the rotation axis X and a main body (Shank) 330 provided at the rear end of the head 310 . The invention is implemented in the head 310 and thus can be implemented in the drill bit itself or in inserts such as insert 350 or spad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com