Thermoplastic resin composition and molded product comprising same

A technology of thermoplastic resin and composition, applied in the field of thermoplastic resin composition and molded products containing the thermoplastic resin composition, which can solve the problems of low gloss, weather resistance of external material physical properties and surface texture limitations, and achieve uniformity Effects of surface gloss, good aesthetics and soft feel, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

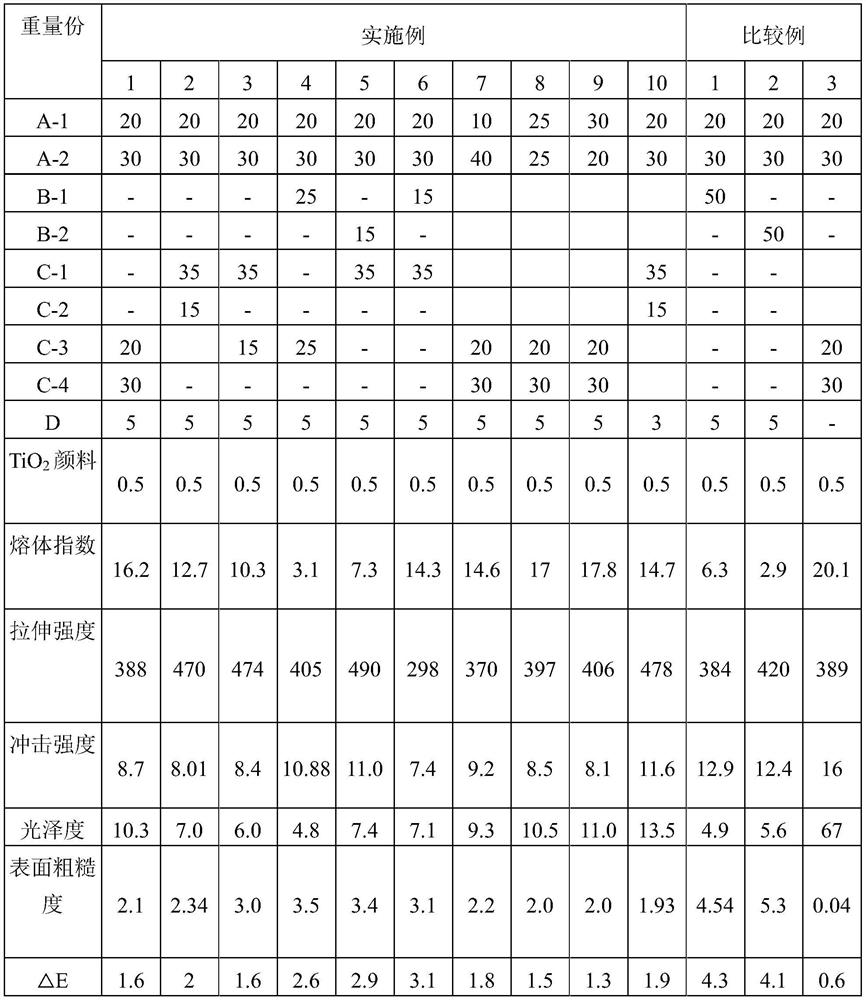

Embodiment 1 to Embodiment 10 and comparative example 1 to comparative example 3

[0110] As shown in Table 1 below, components were prepared according to the contents and kneaded and extruded at 280° C. using a twin-screw extruder to prepare pellets. In addition, a 0.15T sheet was prepared at a molding temperature of 220° C. using the obtained pellets. Then, the gloss and surface roughness values of the films were measured. In addition, the prepared pellets were injected at a molding temperature of 220° C. to prepare test pieces for measuring physical properties. Then, the tensile strength and impact strength of the test specimens were measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap