Finishing method of non-permeable cattle corrected grain leather

A kind of finishing leather and finishing technology, which is applied in the finishing field of non-transparent yellow buffalo leather. It can solve the problems of rough base, discontinuous film formation, and thick fluff, so as to achieve soft, plump and elastic bones, and cover the disabled. The effect of good resistance and uniform surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Example 1 A kind of finishing method of non-transparent yellow cattle repaired leather

[0086] The method comprises the steps of:

[0087] (1) Grinding surface

[0088] Put 240-mesh sandpaper into the leather grinding machine, grind the dry uncoated crust leather, remove the grain layer, make the length of the piles consistent, and the depth of defects become shallower, forming crust A;

[0089] (2) Dust removal

[0090] Clean the surface of the crust A by using a dedusting machine to remove the grinding dust on the surface of the crust A to form the ground crust B;

[0091] (3) Primer

[0092] Dip the primer solution, brush evenly on the surface of the ground leather B, and fill the fiber gaps of the leather at the same time, so that the surface color is basically the same, forming the base leather C;

[0093] Wherein, the active ingredient of described primer comprises:

[0094] Pigment paste 50 g, water 500 g, penetrant 80 g, SB-900 (BRUK ACRYLIC SB-900, acryl...

Embodiment 2-4

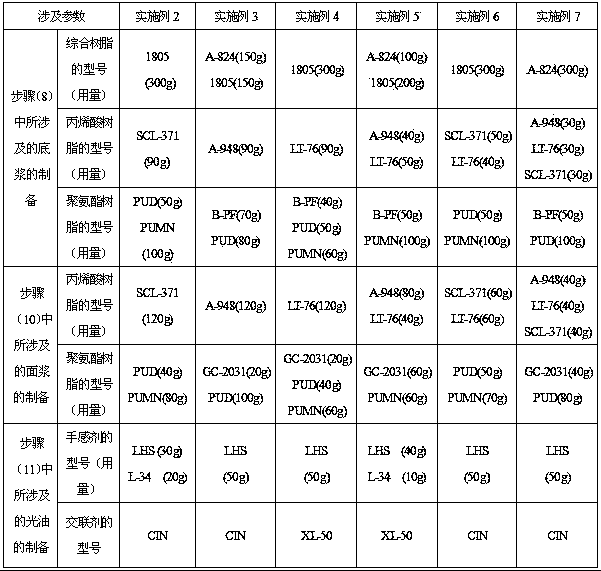

[0148] The finishing method of the impervious dyed yellow cattle trimmed leather used in embodiment 2-4 is similar to the finishing method of embodiment 1, and the difference is only that the parameters used therein are different, specifically as follows:

[0149]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com