A composite resin tanning agent

A technology of composite resin and tanning agent, applied in the field of composite resin tanning agent, to achieve the effect of plump leather, good hand feeling and better leather body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Put 25kg of resin tanning agent R6, 2kg of kaolin, 5kg of sodium sulfate, 4kg of talcum powder, 3kg of sodium lignosulfonate and 1kg of flour into the mixer in sequence, stir for 30 minutes, and then discharge the materials for packaging to obtain the composite resin tanning agent. Among them, resin tanning agent R6 is resin tanning agent R6 with a solid content of 95% and a pH value of 8.5 to 9.5. The particle size of kaolin is 0.2 to 5 µm, the particle size of sodium sulfate is 1800 to 2000 mesh, and the talcum powder The particle size of sodium lignosulfonate is 1200-1500 mesh and 100-150 mesh.

Embodiment 2

[0024] Put 35kg of resin tanning agent R6, 4kg of kaolin, 6kg of sodium sulfate, 5kg of talcum powder, 3.6kg of sodium lignosulfonate and 1.4kg of flour into the mixer in sequence, stir for 30 minutes, and then discharge the materials for packaging to obtain the compound Resin tanning agent; Among them, the resin tanning agent R6 selects the resin tanning agent R6 with a solid content of 95% and a pH value of 8.5-9.5, the particle size of kaolin is 0.2-5 µm, and the particle size of sodium sulfate is 1800-2000 mesh. The particle size of talcum powder is 1200-1500 mesh and that of sodium lignosulfonate is 100-150 mesh.

Embodiment 3

[0026] Put 30kg of resin tanning agent R6, 3kg of kaolin, 5.5kg of sodium sulfate, 4.5kg of talcum powder, 3.3kg of sodium lignosulfonate and 1.2kg of flour into the mixer in order, stir for 30min, and then discharge for packaging, that is Obtain a composite resin tanning agent; wherein, the resin tanning agent R6 selects the resin tanning agent R6 with a solid content of 95% and a pH value of 8.5 to 9.5, the particle size of kaolin is 0.2 to 5 μm, and the particle size of sodium sulfate is 1800 to 2000 μm. Mesh, the particle size of talcum powder is 1200-1500 mesh and the particle size of sodium lignosulfonate is 100-150 mesh.

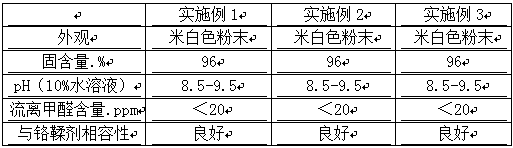

[0027] The physical and chemical indicators of the composite resin tanning agent prepared by Examples 1-3 are shown in Table 1.

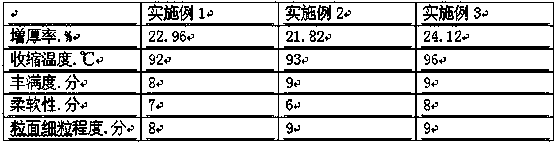

[0028] The application indicators of the composite resin tanning agent prepared in Examples 1-3 to leather retanning are shown in Table 2.

[0029] The physicochemical index of the composite resin tanning agent prepared by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com