A kind of tanning process and its application for multi-component chrome-free combined tanned cow white leather

A technology of combined tanning and wet white leather, applied in the field of multi-component chrome-free combined tanned cow white leather technology, can solve the problems that chrome-free tanning is difficult to combine and use, and achieve the effect of basic thickness, poor antibacterial performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

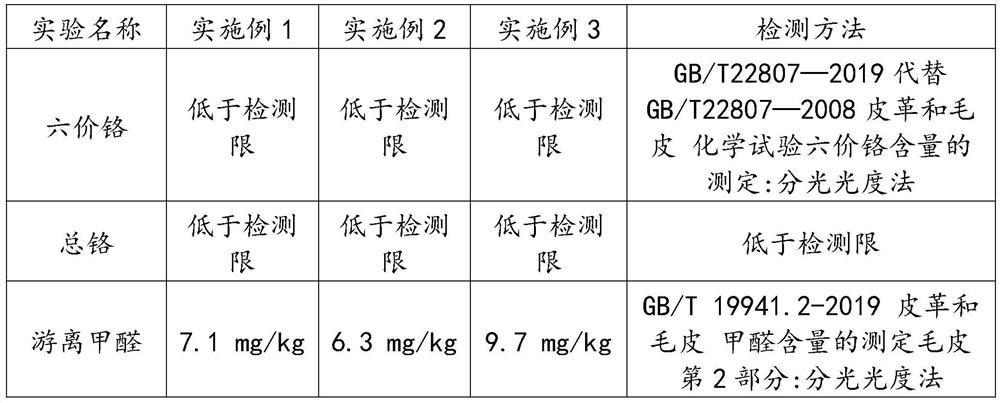

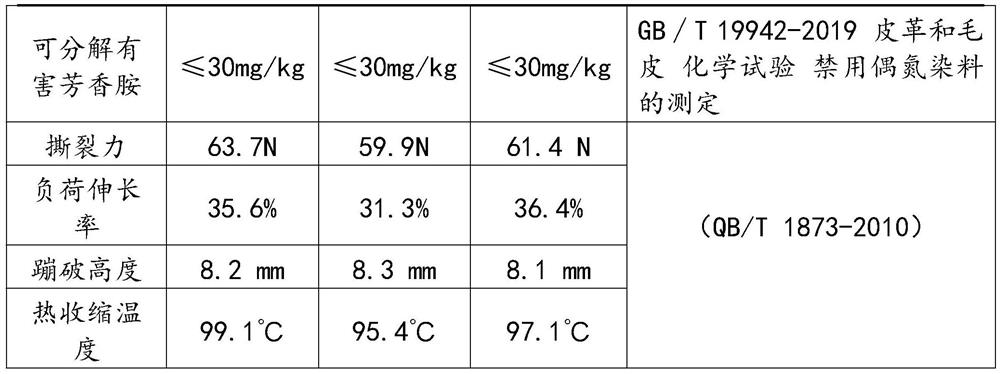

Examples

Embodiment 1

[0041] A multi-component chrome-free combined tanning process for wet white cow leather, at least comprising the following steps:

[0042] Step 1: Preparation of cyclodextrin polyaldehyde derivative MACD:

[0043] Step (1): Dissolve 1 mmol of cyclodextrin in 10 mL of dimethyl sulfoxide to obtain solution A (denoted as 1 part of solution A);

[0044] Step (2): Dissolve 1.2mmol o-iodobenzoic acid in 12mL dimethyl sulfoxide to obtain solution B (denoted as 1 part of solution B);

[0045] Step (3): Add solution B dropwise to solution A, and react for 24 hours to obtain solution C;

[0046] Step (4): Add solution B dropwise to solution C;

[0047] Step (5): Repeat step (4) once to obtain a mixed solution; [at this time, the mixed solution contains 1 part of solution A and 3 parts of solution B]

[0048] Step (6): filter the mixture, drop the filtrate into 200-500ml acetone, and stir at 4°C for 2h;

[0049] Step (7): Centrifuge the step (6) with a refrigerated centrifuge, dissolve...

Embodiment 2

[0064] A multi-component chrome-free combined tanning process for wet white cow leather, at least comprising the following steps:

[0065] Step 1: Preparation of cyclodextrin polyaldehyde derivative MACD:

[0066] Step (1): Dissolve 1 mmol of cyclodextrin in 15 mL of dimethyl sulfoxide to obtain solution A (denoted as 1 part of solution A);

[0067] Step (2): Dissolve 1.2mmol o-iodobenzoic acid in 8mL dimethyl sulfoxide to obtain solution B (denoted as 1 part of solution B);

[0068] Step (3): Add solution B dropwise to solution A, and react for 24 hours to obtain solution C;

[0069] Step (4): Add solution B dropwise to solution C;

[0070] Step (5): Repeat step (4) twice to obtain a mixed solution; [at this time, the mixed solution contains 1 part of solution A and 4 parts of solution B];

[0071] Step (6): filter the mixture, drop the filtrate into 200-500ml acetone, and stir at 4°C for 2h;

[0072] Step (7): Centrifuge the step (6) with a refrigerated centrifuge, disso...

Embodiment 3

[0085] A multi-component chrome-free combined tanning process for wet white cow leather, at least comprising the following steps:

[0086] Step 1: Preparation of cyclodextrin polyaldehyde derivative MACD:

[0087] Step (1): Dissolve 1 mmol of cyclodextrin in 10 mL of dimethyl sulfoxide to obtain solution A (denoted as 1 part of solution A);

[0088] Step (2): Dissolve 1.2 mmol o-iodobenzoic acid in 15 mL dimethyl sulfoxide to obtain solution B (recorded as 1 part of solution B);

[0089] Step (3): Add solution B dropwise to solution A, and react for 24 hours to obtain solution C; [at this time, solution C contains 1 part of solution A and 1 part of solution B]

[0090] Step (4): Filter solution C, drop the filtrate into 200-500ml acetone, and stir at 4°C for 2h;

[0091] Step (5): Centrifuge step (4) with a refrigerated centrifuge, dissolve the filter residue with deionized water, filter, and then freeze-dry the filtrate to obtain cyclodextrin polyaldehyde derivatives.

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear load | aaaaa | aaaaa |

| tear load | aaaaa | aaaaa |

| tear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com