Sliding type positioning and cutting device for notebook computer shell injection molding part

A notebook computer and material cutting device technology, applied in the direction of metal processing, etc., can solve the problems that affect the quality of injection molded parts of notebook computer casings and the effect of later use, easily reduce the efficiency and accuracy of cutting materials, and damage the injection molded parts of notebook computer casings. , to achieve the effect of guaranteeing quality and post-use effect, improving cutting efficiency and cutting accuracy, and improving the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

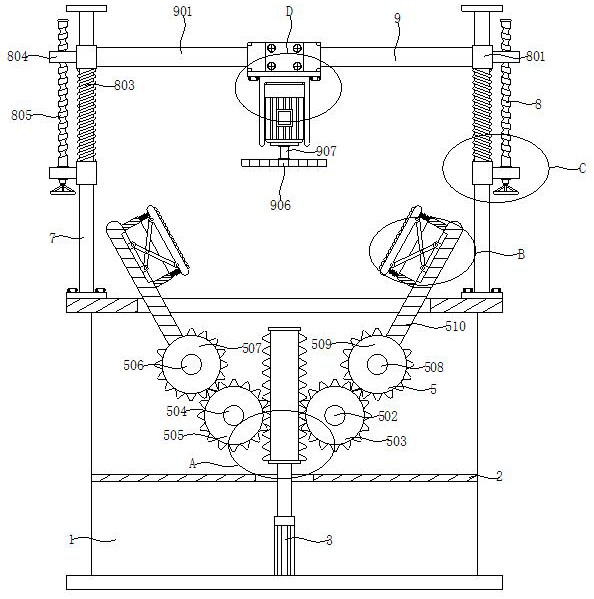

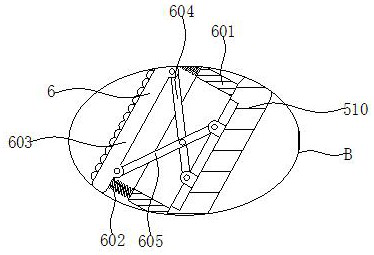

[0026] see Figure 1-7 , the present invention provides a technical solution: a sliding type positioning and cutting device for injection molded parts of a notebook computer shell, including a bow-shaped plate 1, a reinforcement plate 2 is fixedly installed on the rear inner wall of the bow-shaped plate 1, and the inner bottom of the bow-shaped plate 1 is fixedly installed There is an electric push rod 3, a circular opening is opened on the reinforcement plate 2, the free end of the electric push rod 3 passes through the circular opening and is fixedly connected with a connector 4, and the top of the reinforcement plate 2 is provided with a positioning mechanism 5 and a limit mechanism 6, The top outer surface of the bow-shaped plate 1 is fixedly connected with two sets of slide bars 7 by bolts, and the two sets of slide bars 7 are provided with a height adjustment mechanism 8 and a material cutting mechanism 9, and the top of the bow-shaped plate 1 is provided with a long open...

Embodiment 2

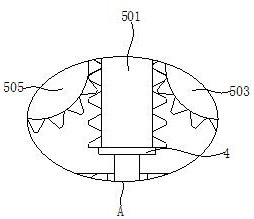

[0028] see Figure 1-7, on the basis of Embodiment 1, the positioning mechanism 5 includes a double-sided gear plate 501, a first rotating rod 502, a first gear 503, a second rotating rod 504, a second gear 505, a third rotating rod 506, a third gear 507, the fourth rotating rod 508, the fourth gear 509 and the positioning plate 510, the top outer surface of the connector 4 is fixedly connected with a double-sided toothed plate 501, and the rear side inner wall of the arcuate plate 1 is rotatably equipped with the first rotating rod 502, the second Two rotating rods 504, the third rotating rod 506 and the fourth rotating rod 508, the first rotating rod 502 is fixedly sleeved with a first gear 503, the second rotating rod 504 is fixedly sleeved with a second gear 505, and the third rotating rod 504 is fixedly sleeved with a second gear 505. The fixed sleeve on the rod 506 is provided with a third gear 507, the fixed sleeve on the fourth rotating rod 508 is provided with a fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com