Environment-friendly type sound-absorbing flame-retardant sponge processing machinery and processing process thereof

A processing machinery, environmentally friendly technology, used in metal processing, coiling strips, thin material processing, etc., can solve problems such as increased workload of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

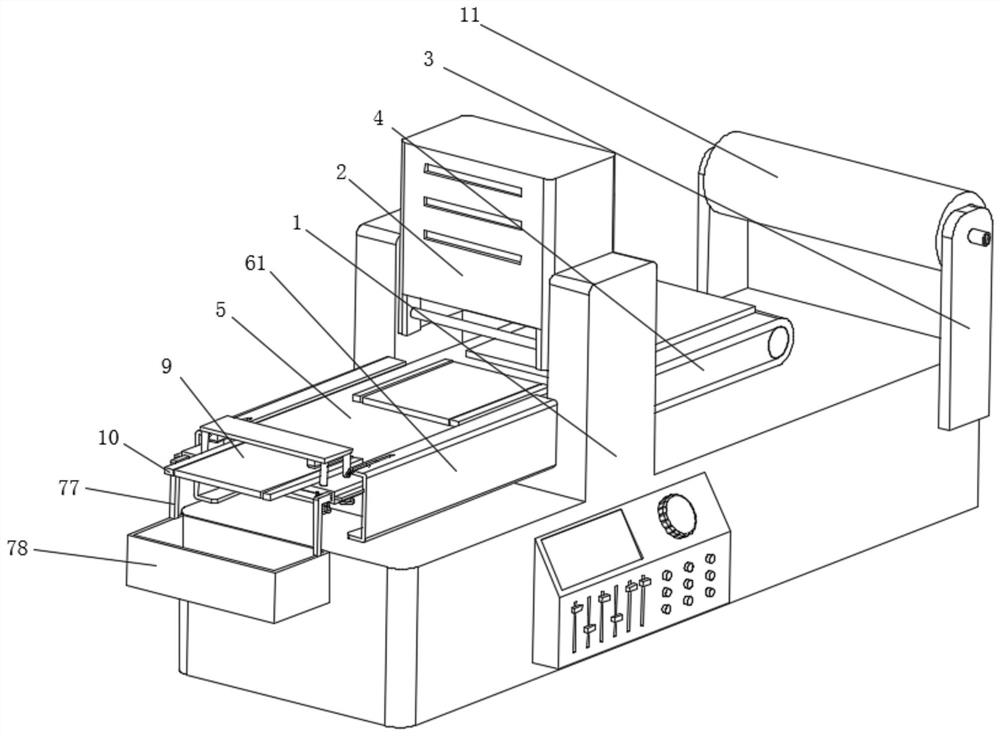

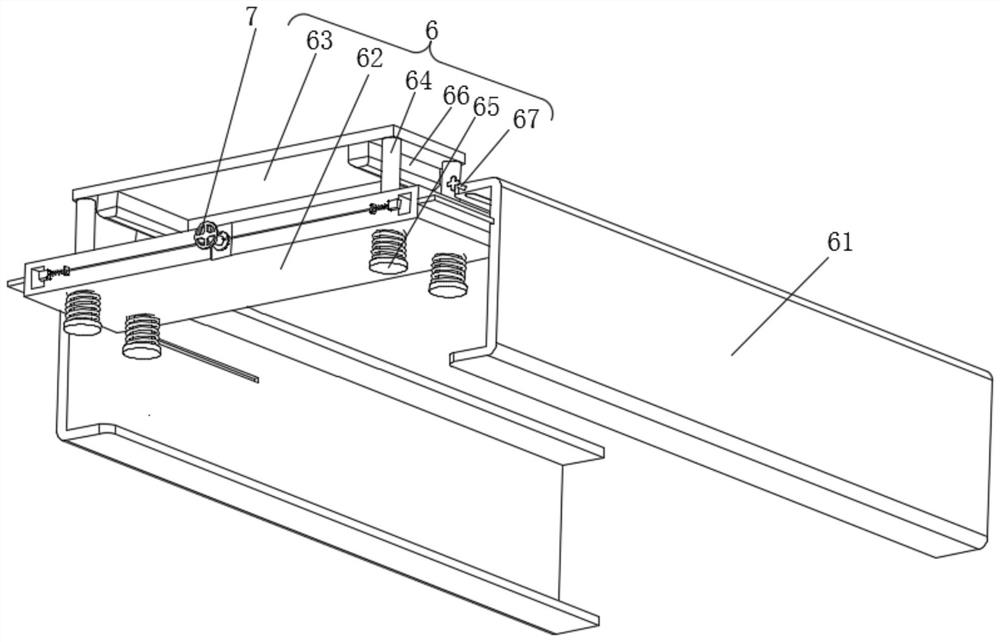

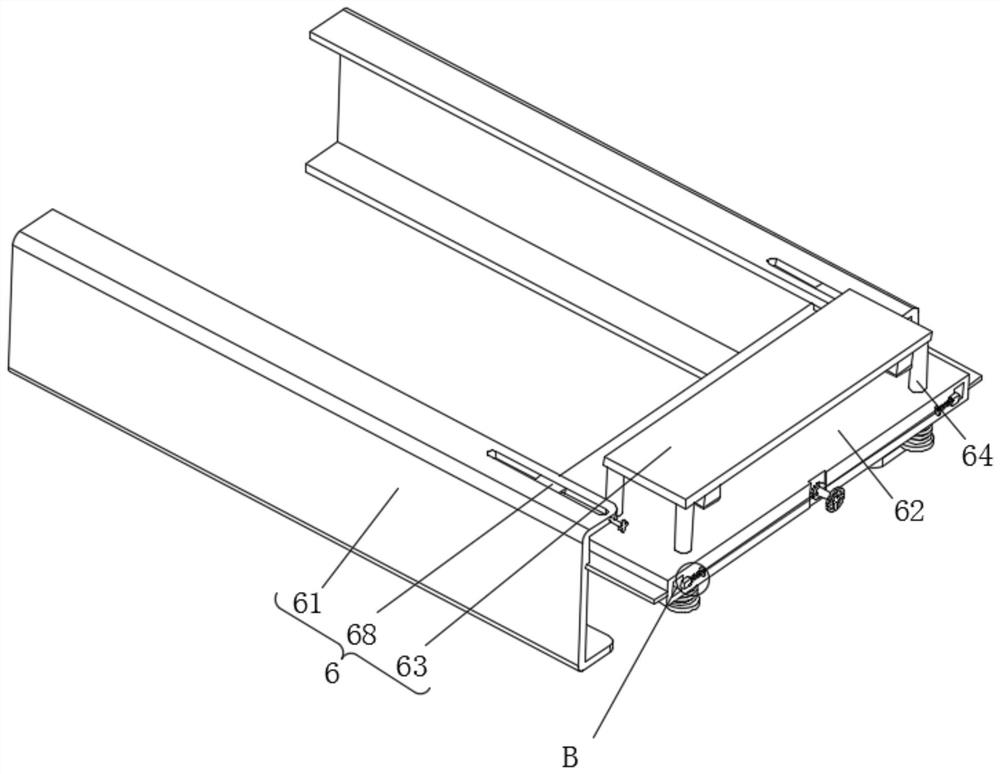

[0034] Example 1, such as Figure 1-11 As shown, the present invention provides an environmentally friendly sound-absorbing and flame-retardant sponge processing machine, including a workbench 1 and a limit structure 6, the surface of the workbench 1 is slidably connected to a cutting machine 2, and the side wall of the workbench 1 is fixedly connected to a connection The plate 3 and the position of the workbench 1 relative to the cutting machine 2 are fixedly connected with a fixed plate 4, the surface of the fixed plate 4 is connected with a conveyor belt 5, and the surface of the conveyor belt 5 is movably connected with a sponge plate 9 and waste corners 10, and the workbench 1 A position limiting structure 6 is provided relative to the position of the conveyor belt 5 .

[0035] Let's talk about the specific setting and function of its position-limiting structure 6, collecting structure 7 and auxiliary structure 8 in detail below.

[0036] Such as figure 1 and Figure 4...

Embodiment 2

[0040] Embodiment 2, on the basis of embodiment 1, as figure 1 and Figure 10 As shown, the surface of the connecting plate 3 is provided with a cylinder 12, the surface of the cylinder 12 is covered with a sponge roll 11, the inside of the connecting plate 3 is provided with an auxiliary structure 8, the auxiliary structure 8 includes a long tube 81, the surface of the long tube 81 and The connecting plate 3 is slidingly connected, and the inner wall of the long tube 81 is rotatably connected with a rotating rod 82, and the surface of the rotating rod 82 is fixedly connected with a round bar 84, and the inner wall of the long tube 81 is fixedly connected with a limit block 83, and the round bar 84 is rotated and inserted in the limit block. Inside the bit block 83, the round bar 84 is fixedly connected with a gear 85 at one end away from the rotating rod 82, and the inside of the long tube 81 is slidably inserted with a slide bar 86, and the arc surface of the long tube 81 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com