Preparation method and application of polylactic acid/chitosan/honeysuckle chlorogenic acid nanofiber membrane

A technology of honeysuckle chlorogenic acid and nanofiber membranes, applied in the fields of application, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of low fiber membrane strength, antibacterial and anticorrosion performance that cannot meet practical application requirements, and difficult antibacterial Function and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of polylactic acid / chitosan / honeysuckle chlorogenic acid nanofiber membrane, comprising extraction and electrospinning of honeysuckle chlorogenic acid.

[0034] Further, the extraction method of honeysuckle chlorogenic acid is:

[0035] S1: Wash and dry the honeysuckle flower and crush it to below 200 mesh to obtain the honeysuckle powder, which is set aside;

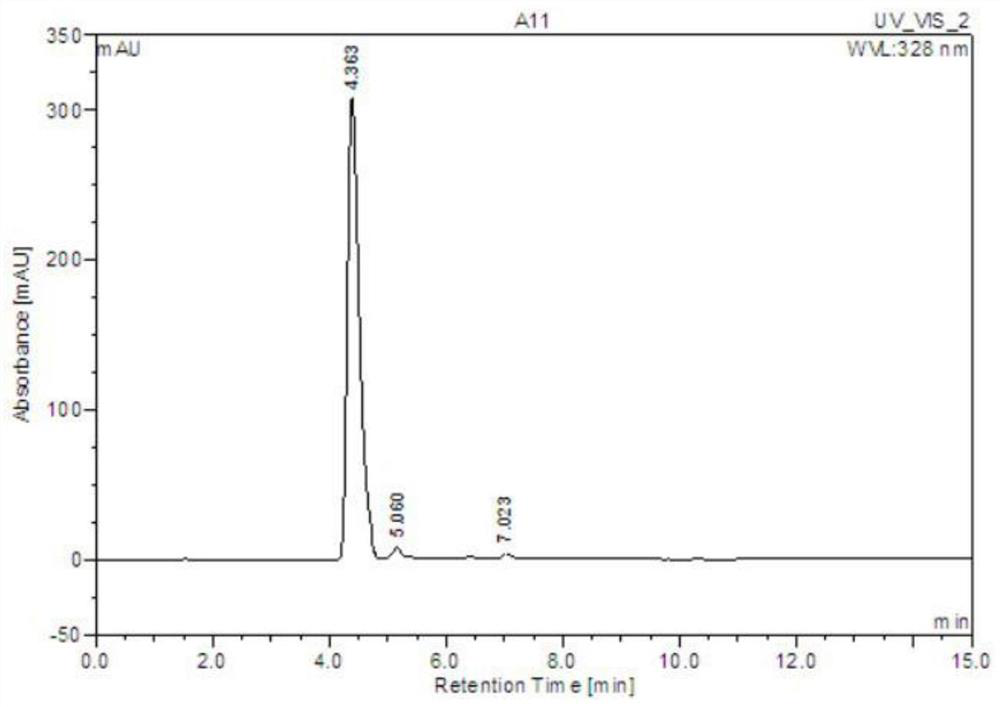

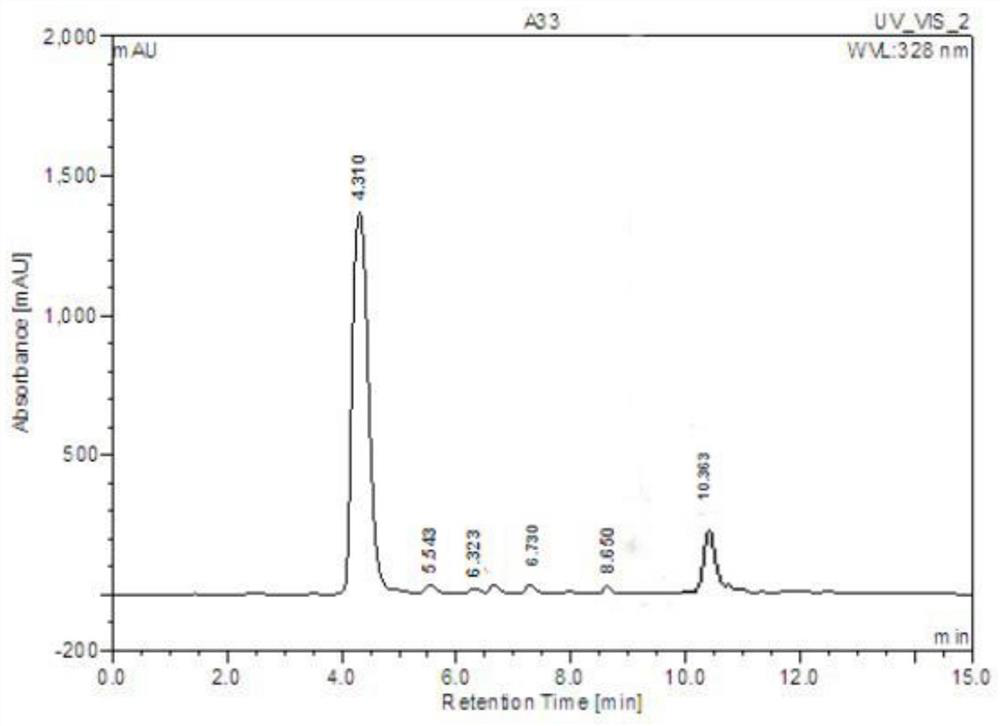

[0036] S2: adding honeysuckle powder into a mixed solution of ethanol and ethyl acetate, soaking for 5 hours, and performing microwave extraction;

[0037] S3: Ultrasonic treatment after microwave extraction, and then filtration. The filtrate is saturated and adsorbed through a macroporous resin adsorption column. After adsorption, it is eluted with ethanol aqueous solution. The eluate is collected, concentrated, and solvent-removed to obtain chlorogenic acid.

[0038] Further, the solid-liquid ratio of the mixed solution of honeysuckle, ethanol and ethyl acetate in step S2 is 40:1mL·g -1 ;...

Embodiment 2

[0045] A preparation method of polylactic acid / chitosan / honeysuckle chlorogenic acid nanofiber membrane, comprising extraction and electrospinning of honeysuckle chlorogenic acid. The extraction part of honeysuckle chlorogenic acid is the same as that in Example 1.

[0046] Further, the method of electrospinning is:

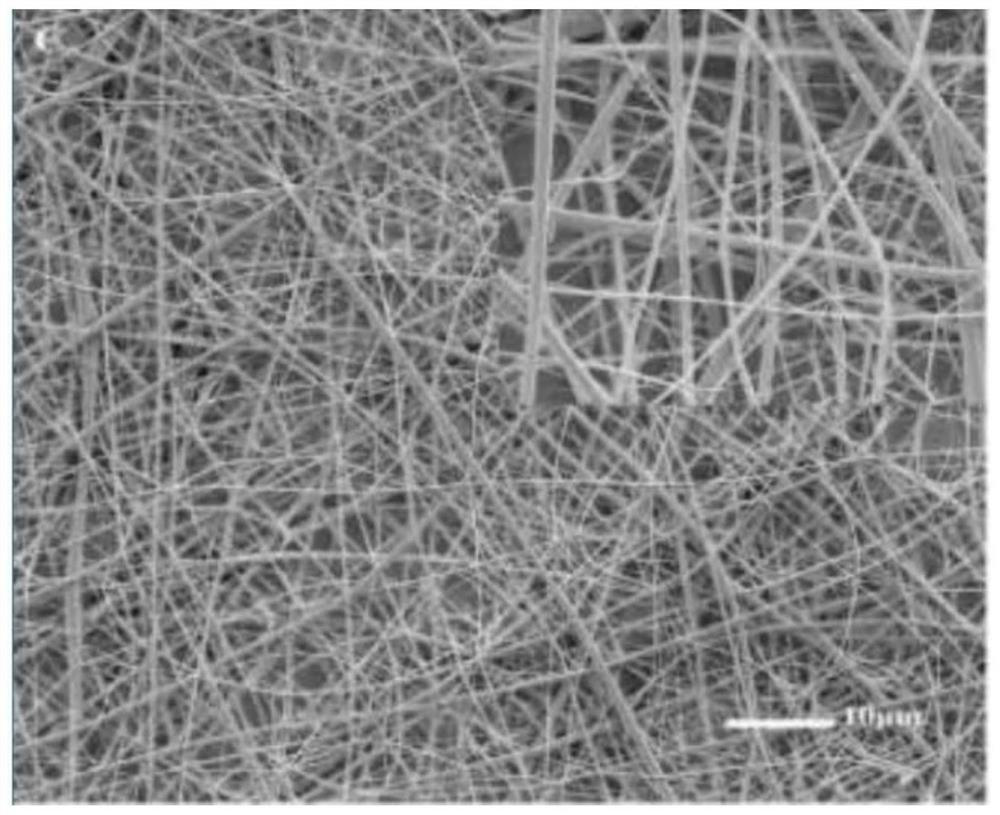

[0047]A1: Chitosan and polylactic acid were mixed and added to hexafluoroisopropanol according to the mass ratio of 1:1 to prepare a spinning solution with a concentration of 10% w / v, and then the extracted honeysuckle chlorogenic acid was added. Stir at a constant temperature for 12 hours to obtain a spinning solution;

[0048] A2: Put the electrospinning blend liquid into the syringe, and use the DP30 electrospinning equipment to carry out electrospinning, the voltage is set to 25kV, and the advancing speed is 0.01mm / h; the receiving material is set to aluminum foil, and the spinning needle is sent to the receiving device The distance between them is 10cm. Af...

Embodiment 3

[0052] A preparation method of polylactic acid / chitosan / honeysuckle chlorogenic acid nanofiber membrane, comprising extraction and electrospinning of honeysuckle chlorogenic acid. The extraction part of honeysuckle chlorogenic acid is the same as that in Example 1.

[0053] Further, the method of electrospinning is:

[0054] A1: Chitosan and polylactic acid were mixed and added to hexafluoroisopropanol according to the mass ratio of 1:1 to prepare a spinning solution with a concentration of 10% w / v, and then the extracted honeysuckle chlorogenic acid was added. Stir at a constant temperature for 12 hours to obtain a spinning solution;

[0055] A2: Put the electrospinning blend liquid into the syringe, and use the DP 30 electrospinning equipment to carry out electrospinning, the voltage is set to 25kV, and the advancing speed is 0.01mm / h; set the receiving material to aluminum foil, and the spinning needle to the receiving The distance between the devices is 10cm. After the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com