A kind of prestressed anchor cable structure and prestressed anchor cable construction method

A technology of prestressed anchor cables and anchor cables, which is applied in the direction of foundation structure engineering, structural elements, excavation, etc., can solve problems affecting the stability of anchor cables, and achieve the effect of enhancing the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

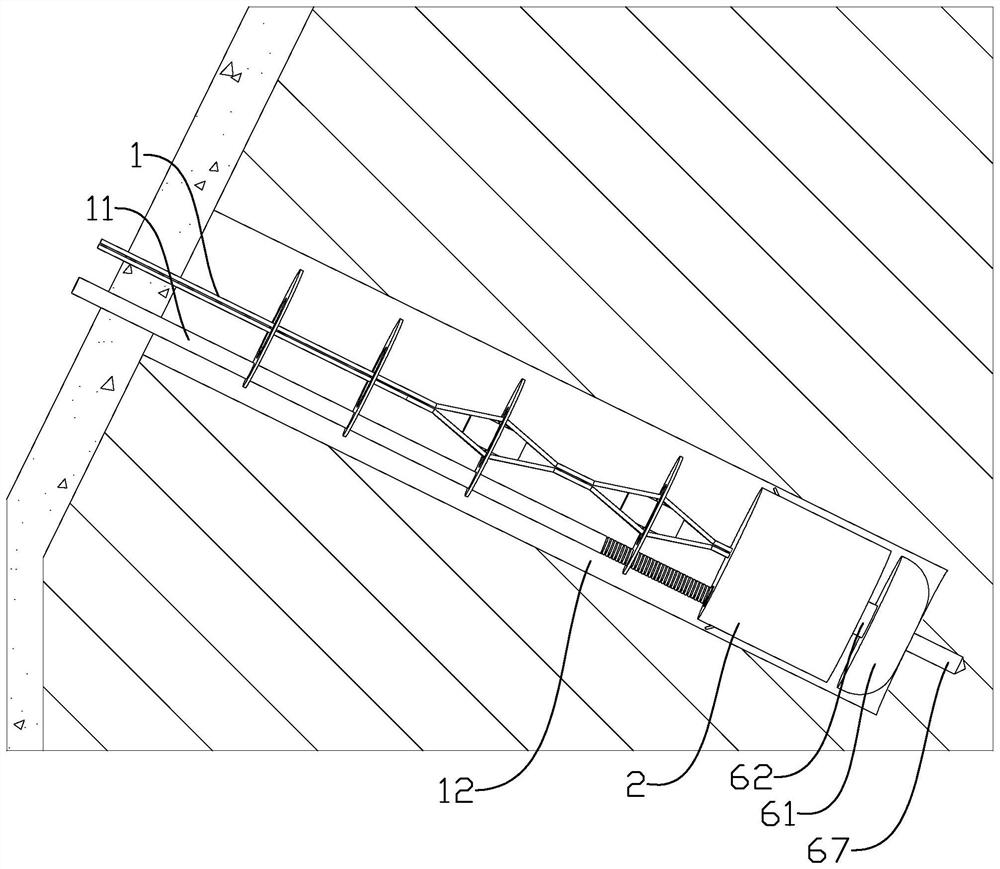

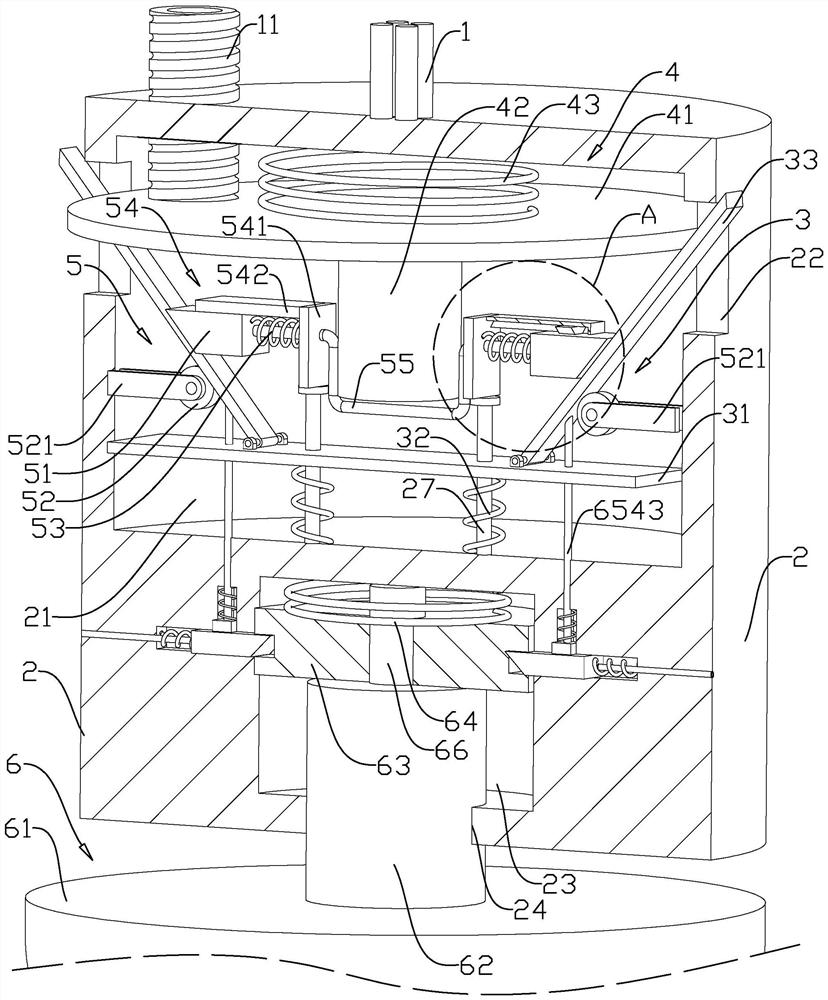

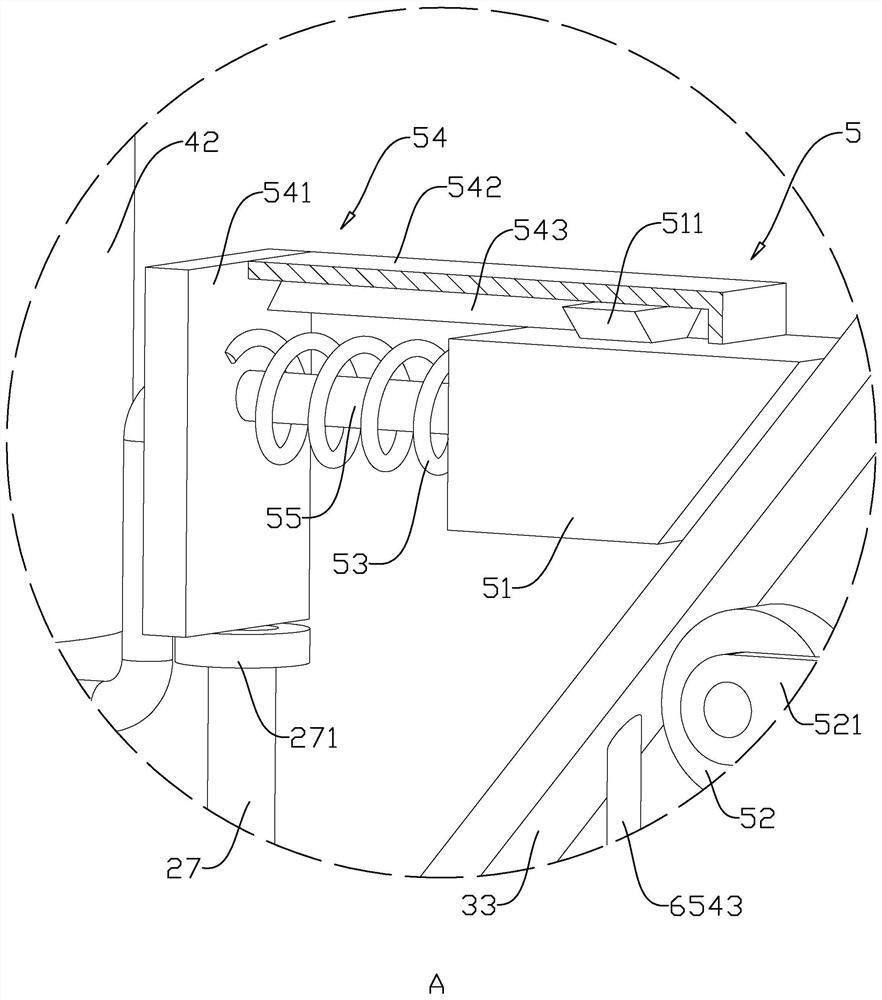

[0039] Attached to the following Figure 1-5 This application will be described in further detail.

[0040] The embodiment of the present application discloses a prestressed anchor cable structure, such as figure 1 and figure 2 As shown, the prestressed anchor cable structure includes an anchor cable 1 and a grouting pipe 11. An anchor cable hole 12 is opened in the soil layer. A support plate, and a fixed block 2 is fixedly connected to the end of one end of the anchor cable 1 . The grouting pipe 11 passes through a plurality of support plates in sequence, and one end of the grouting pipe 11 is threadedly connected with the fixing block 2 . Both the grouting pipe 11 and the anchor cable 1 are partially located in the anchor cable hole 12 , and the fixing block 2 is located in the anchor cable hole 12 . By arranging the support plate, it is convenient to reduce the possibility that the anchor cable 1 is fitted with the inner wall of the anchor cable hole 12 .

[0041] li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com