Joint connecting structure and assembly type beam frame

A node connection and connector technology, which is applied in the direction of building structure and construction, and can solve the problem that the welding position affects the strength of the node connection structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

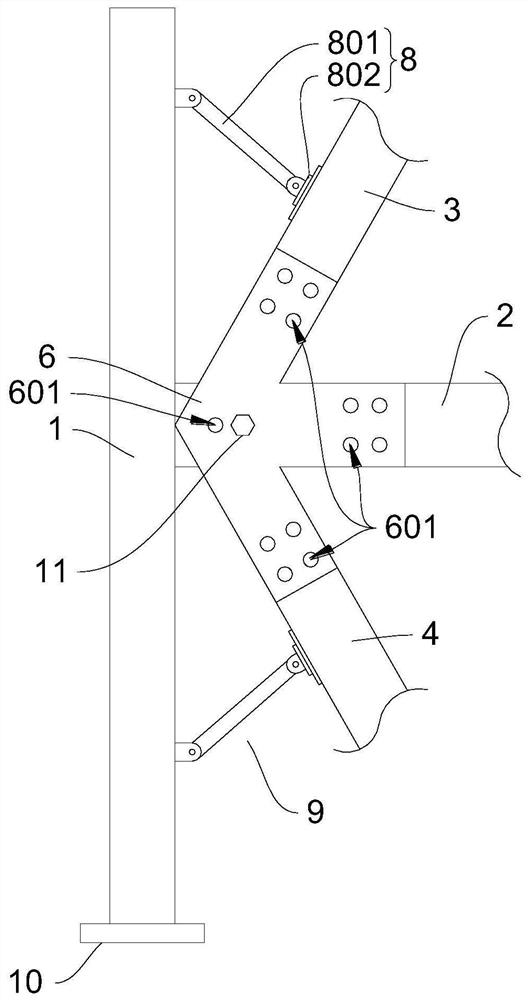

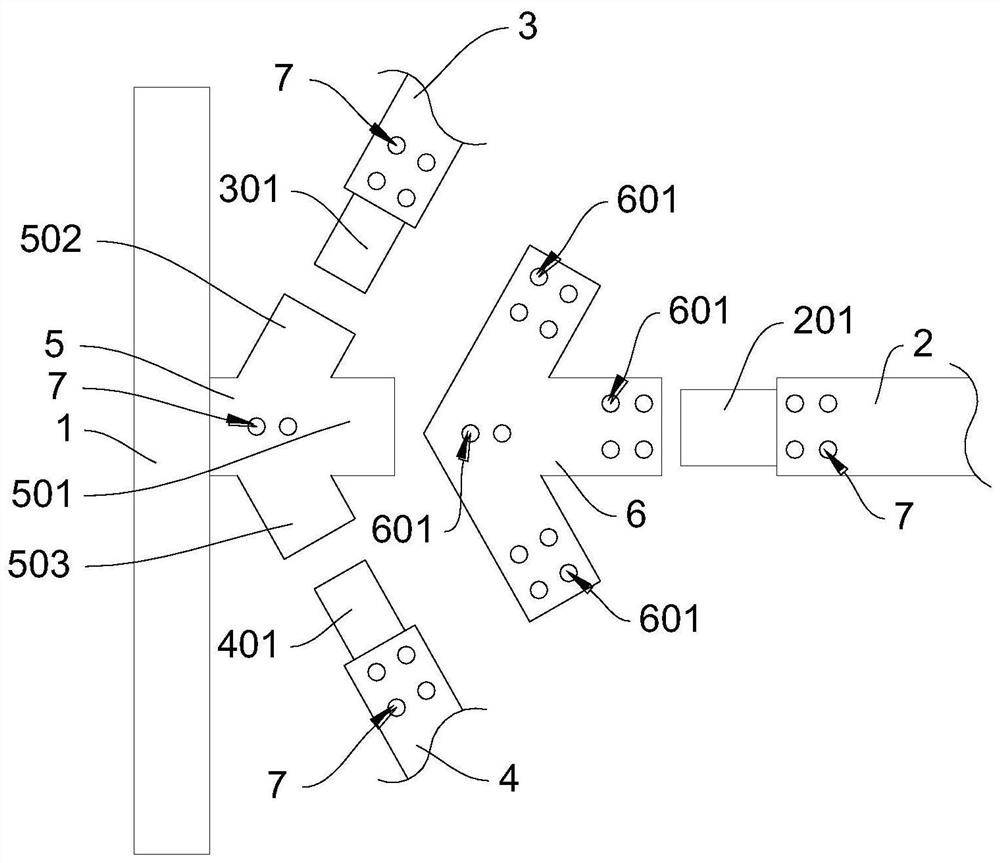

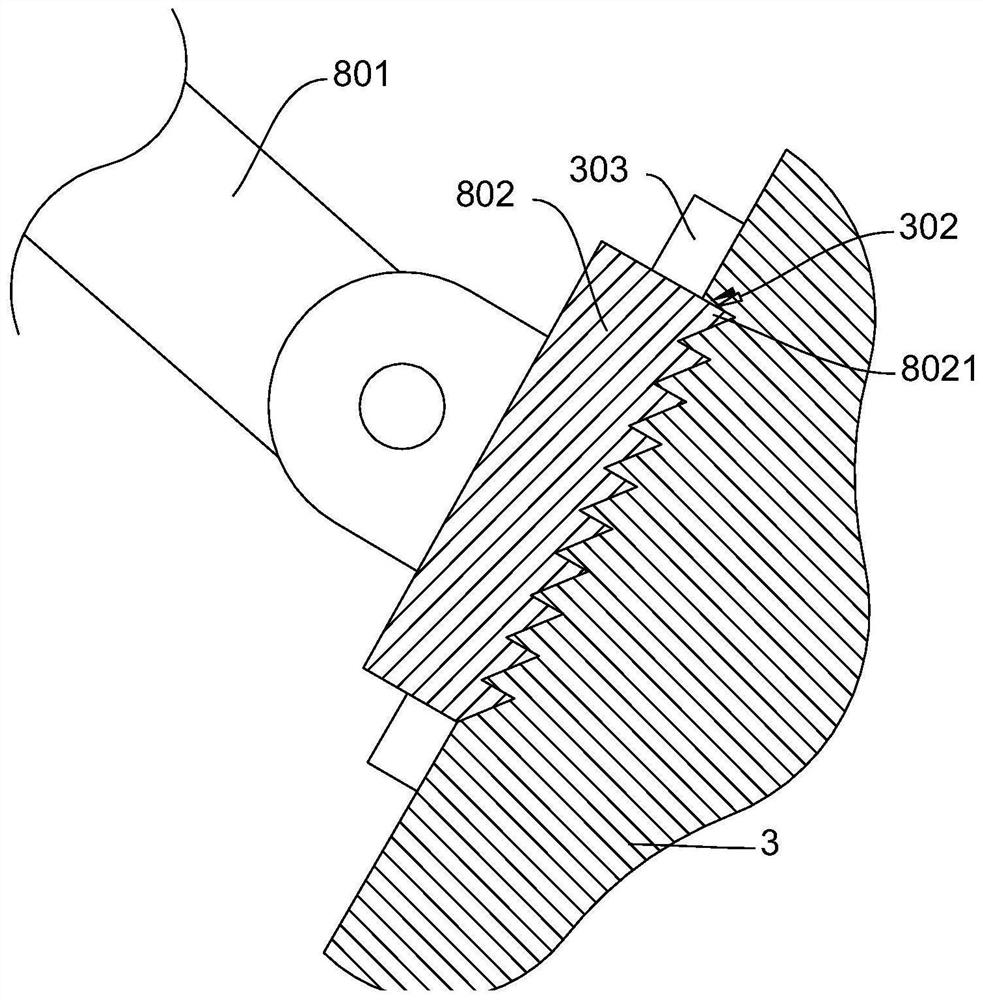

[0039] Please refer to Figure 1 to Figure 6, shows a node connection structure and a prefabricated beam frame provided by an embodiment of the present invention, and the details are as follows.

[0040] Such as figure 1 with figure 2 As shown, the embodiment of the present invention provides a node connection structure, which includes a main beam 1, a cross beam 2, a first inclined support beam 3, a second inclined support beam 4, a connecting head 5 and a connecting piece 6, wherein the main beam 1, The beam 2, the first slanting support beam 3 and the second slanting support beam 4 are all made of rectangular steel. The main beam 1 is arranged vertically to provide vertical support, and the crossbeam 2 is arranged horizontally to provide horizontal support. The first slanting support beam 3 and the second slanting support beam 4 are arranged inclined upwards and downwards respectively to provide support in an oblique direction. The connecting head 5 plays the role of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com