Wear-resistant and collision-resistant echo probe for ultrasonic flaw detection

An ultrasonic and echo technology, which is applied in the direction of material analysis, measurement device, and instrument using sonic/ultrasonic/infrasonic waves, can solve the problem that the echo probe is easily damaged, the echo probe is inconvenient to adjust, and the echo probe is wear-resistant and collision-resistant. It can avoid problems such as unsatisfactory performance and achieve the effect of avoiding wear, improving wear resistance and good collision resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

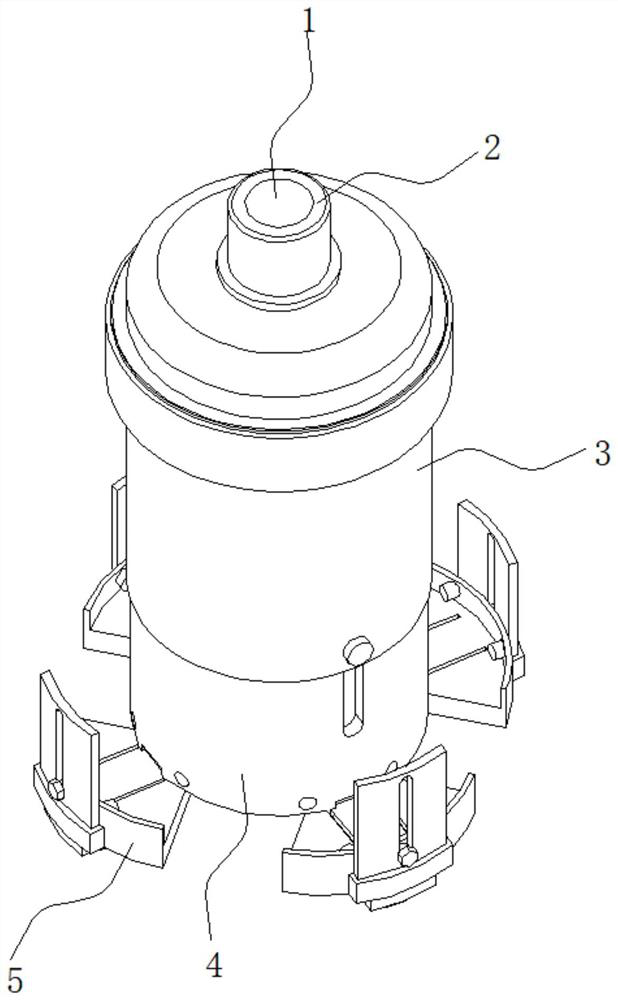

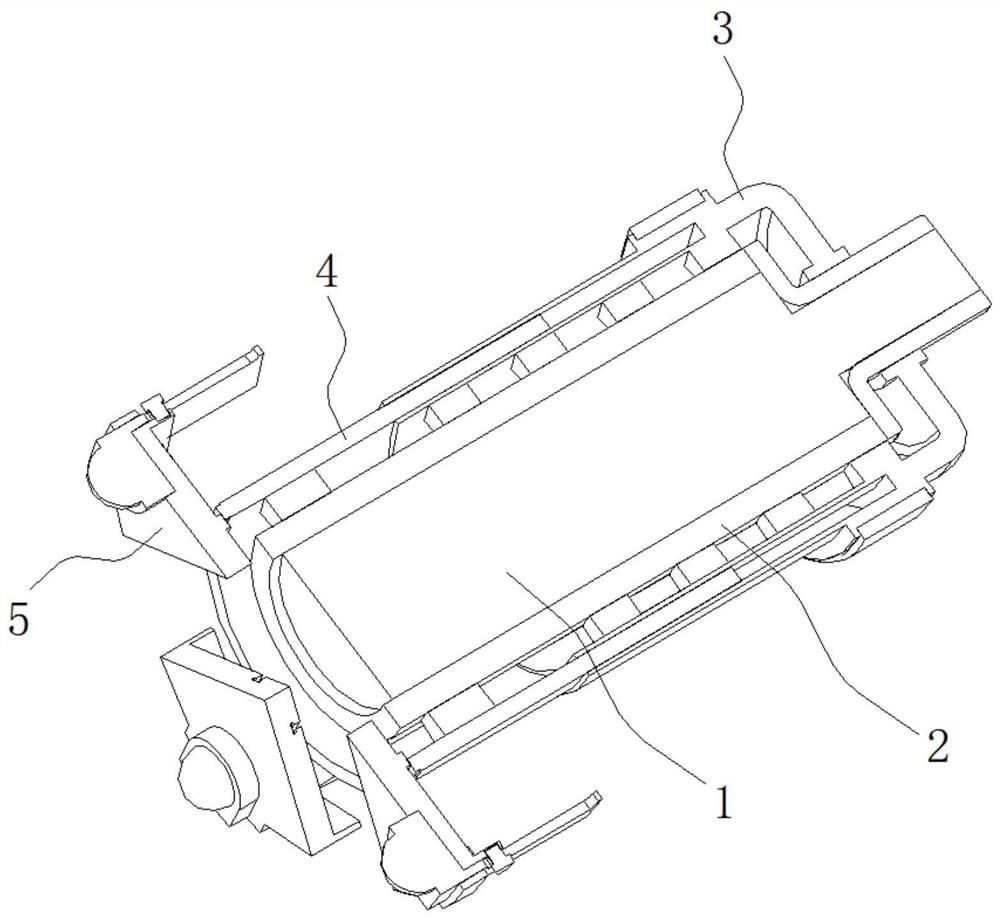

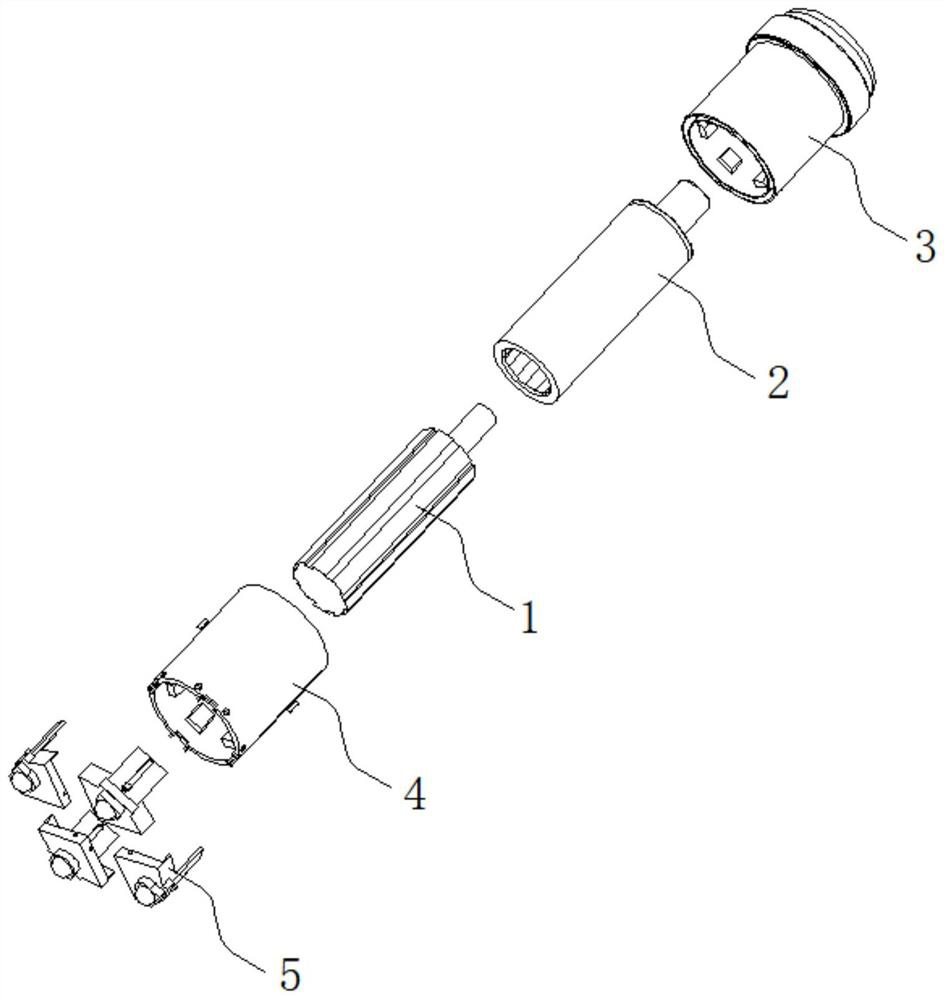

[0040] see Figure 1-3 As shown, the present invention is a wear-resistant and collision-resistant ultrasonic flaw detection echo probe, which includes a probe body 1, a wear-resistant layer 2, an outer protective tube 3 and an inner protective tube 4, and the outer surface of the probe body 1 is fixedly sleeved There is a wear-resistant layer 2, and an outer protective tube 3 is fixed on the outer surface of the wear-resistant layer 2. The bottom of the outer protective tube 3 is movably inserted with an inner protective tube 4, and the bottom of the inner protective tube 4 is provided with four uniformly distributed along the circumference. Bottom mechanism 5.

[0041] Among them such as Figure 4-5As shown, the wear-resistant layer 2 includes a side wear-resistant ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com