Light-load hanging belt type conveying system

A belt-type conveying and light-load technology, which is applied in the direction of conveyors, transportation and packaging, packaging, etc., can solve the problems of not being suitable for fast transportation of light-weight items, increasing production costs, and high manufacturing requirements, so as to improve service life and reduce errors. The chance of avoiding collision and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

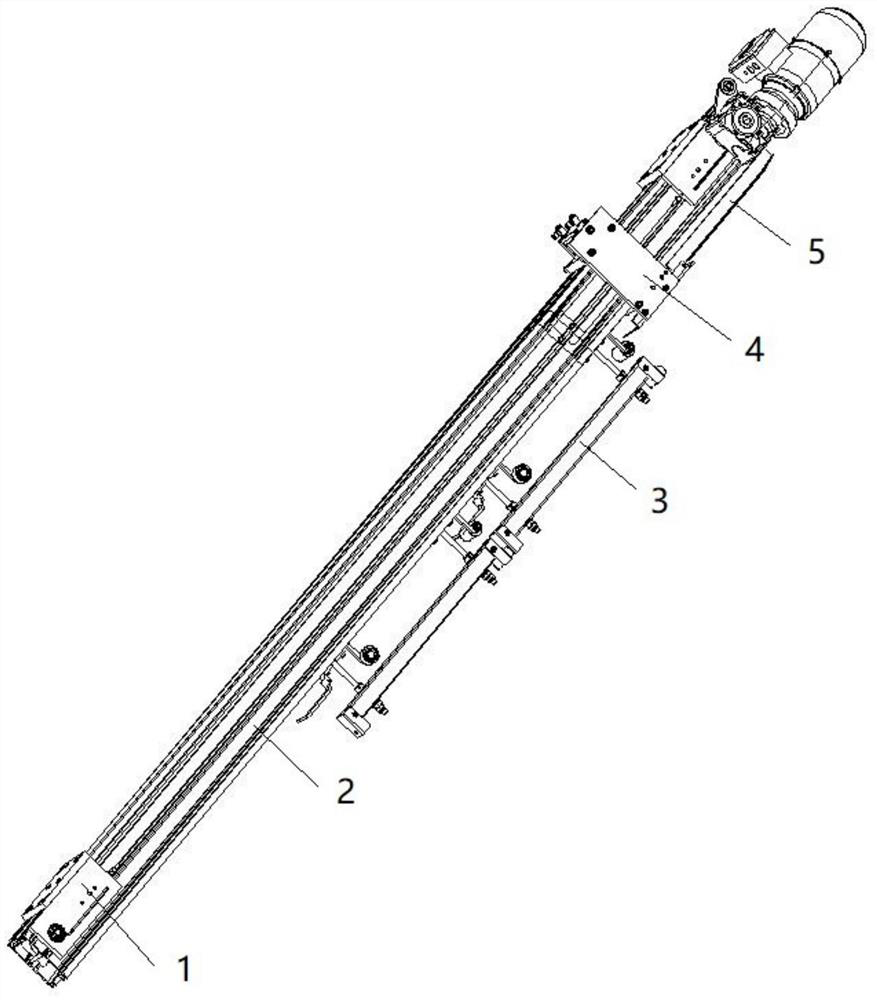

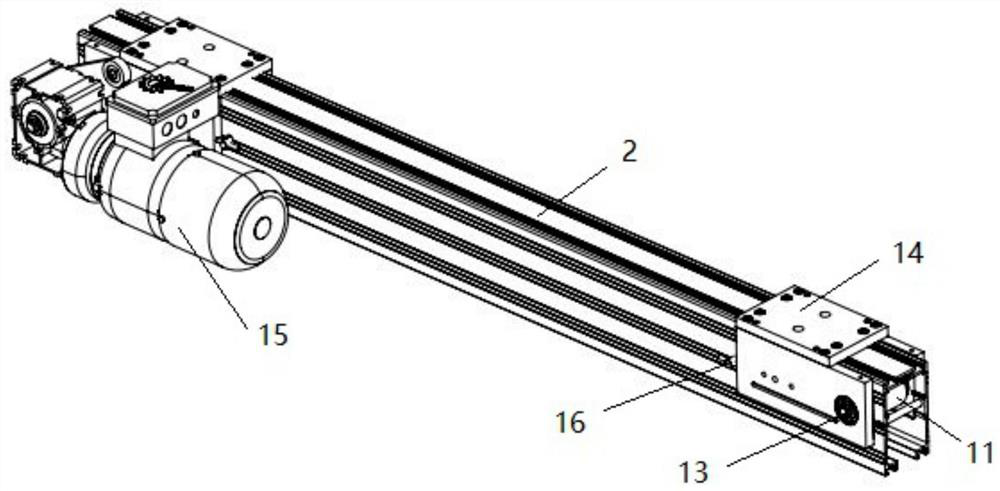

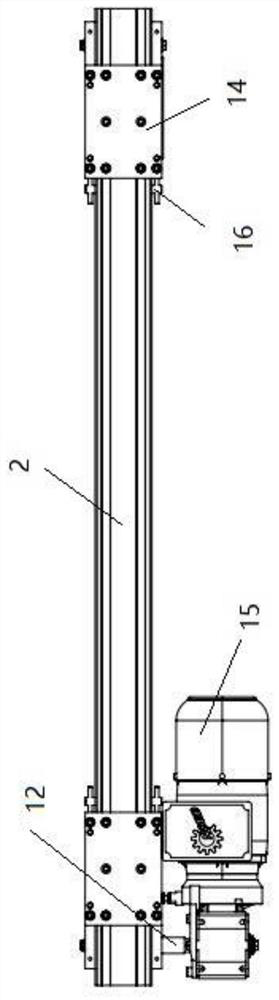

[0038] if Figure 1-11 As shown, a light-load suspended belt conveyor system includes a drive belt 1, a guide rail 2, a transport vehicle 3 and a stopper 4, the guide rail 2 is provided with a drive belt 1, and the lower end of the guide rail 2 is provided with a plurality of transport Vehicle 3, the transport vehicle 3 is driven by the drive belt 1 to move along the track 2, the transport vehicle 3 includes a front vehicle group 31, a rear vehicle group 32 and a connecting crossbeam 33, and the front end of the connecting crossbeam 33 is provided with a front end along the moving direction. Vehicle group 31, the rear end is provided with rear vehicle group 32, and described front vehicle group 31 comprises vehicle body 311, mobile guiding mechanism, 310 first front vehicle brakes, and described vehicle body 311 is provided with mobile guiding mechanism, described The mobile guiding mechanism is slidingly connected with the guide rail 2, and the first front vehicle brake 310 i...

Embodiment 2

[0043] if Figure 1-11 As shown, a light-load suspended belt conveyor system includes a drive belt 1, a guide rail 2, a transport vehicle 3 and a stopper 4, the guide rail 2 is provided with a drive belt 1, and the lower end of the guide rail 2 is provided with a plurality of transport Vehicle 3, the transport vehicle 3 is driven by the drive belt 1 to move along the track 2, the transport vehicle 3 includes a front vehicle group 31, a rear vehicle group 32 and a connecting crossbeam 33, and the front end of the connecting crossbeam 33 is provided with a front end along the moving direction. Vehicle group 31, the rear end is provided with rear vehicle group 32, and described front vehicle group 31 comprises vehicle body 311, mobile guiding mechanism, 310 first front vehicle brakes, and described vehicle body 311 is provided with mobile guiding mechanism, described The mobile guiding mechanism is slidingly connected with the guide rail 2, and the first front vehicle brake 310 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com