Self-sealing loading unit and open type load box structure based on self-sealing loading unit

A loading unit and self-sealing technology, which is applied in basic structure engineering, basic structure test, construction, etc., can solve the problems of complex structure, stability, poor sealing, etc., to ensure stability and reliability, and realize self-sealing effect , Improve the efficiency of production and installation

Pending Publication Date: 2021-07-30

ZHEJIANG OUGAN MASCH CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing loading unit is an oil cylinder type loading

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

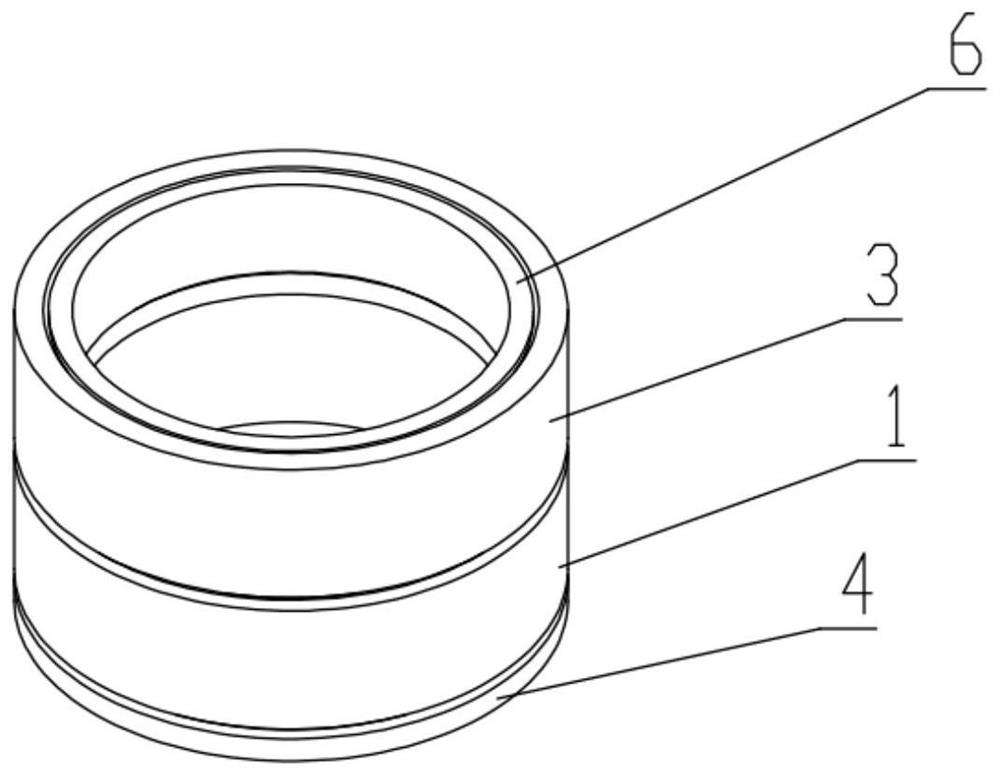

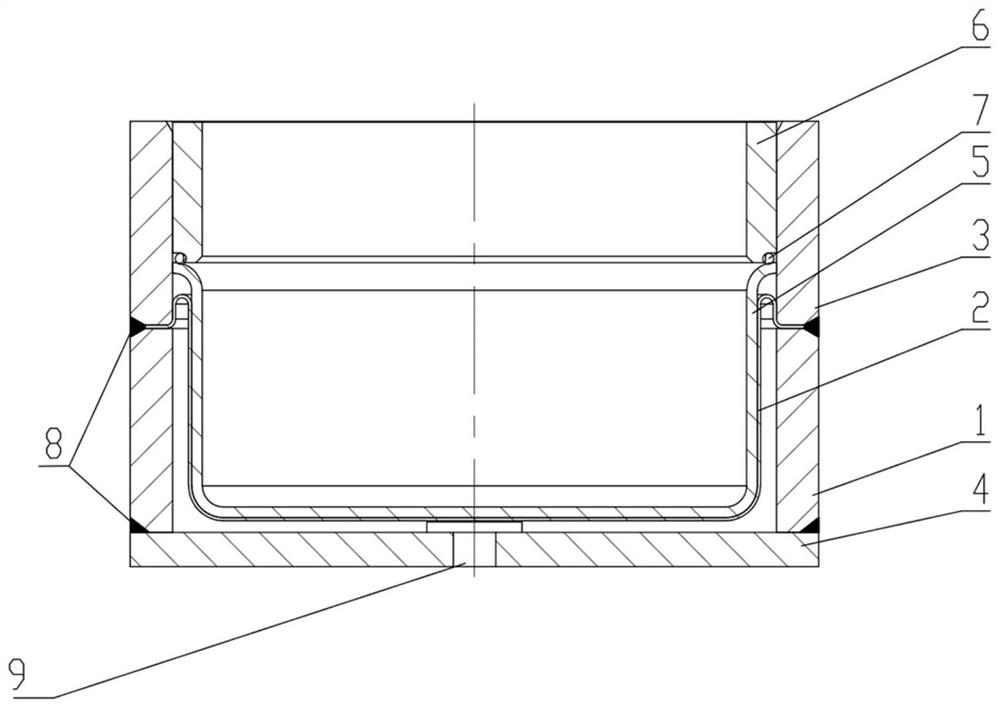

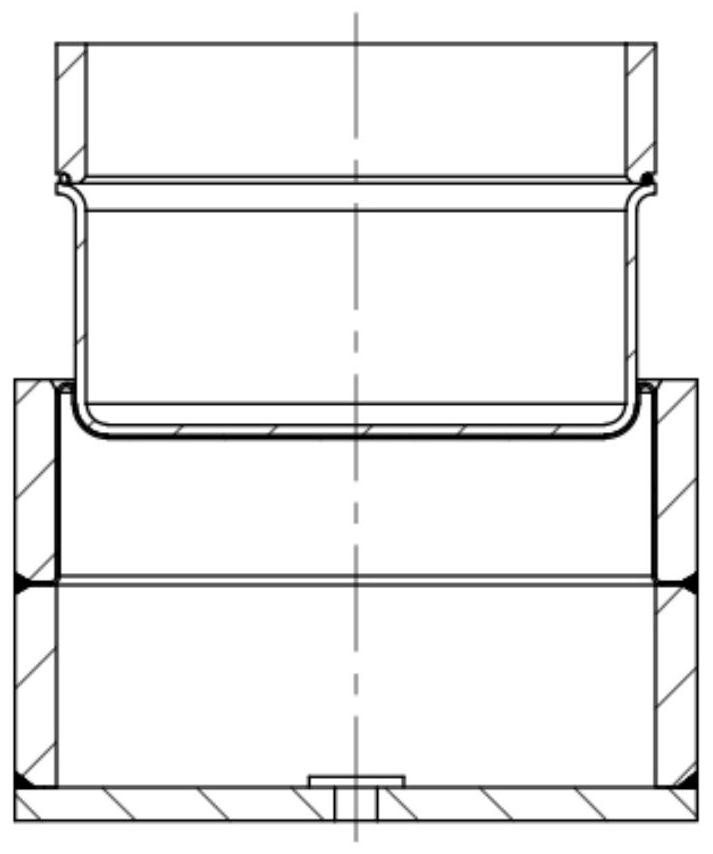

The invention discloses a self-sealing loading unit and an open type load box structure based on the self-sealing loading unit. According to the self-sealing loading unit and the open type load box structure based on the self-sealing loading unit, an upper steel sleeve and a lower steel sleeve are welded, a bottom plate is welded to the bottom face of the lower steel sleeve, a sealing ring is arranged above the bottom plate, the edge of the sealing ring is arranged between the upper steel sleeve and the lower steel sleeve, the upper steel sleeve, the lower steel sleeve, the sealing ring and the bottom plate are combined to form a loading cavity, a lining is placed above the sealing ring, the bottom face of the lining is connected with the sealing ring, the sealing ring moves up and down to enable the loading cavity to ascend or descend, the lining is driven to ascend or descend, loading units, upper base plates installed above the loading units and lower base plates installed below the loading units are combined into loading unit assemblies, the multiple loading unit assemblies are annularly arranged, and reinforcing rings are welded to the upper portions and the lower portions of the loading unit assemblies. According to the self-sealing loading unit, the working stability of the loading units is improved, the modular structure of the open type load box is realized, the production and installation efficiency of the load box is improved, and the working stability and reliability of the load box in a self-balancing static load test system are ensured.

Description

technical field [0001] The invention relates to the field of static load detection of self-balancing pile foundations, in particular to a self-sealing loading unit and an open load box structure based on the unit. Background technique [0002] Self-balancing pile foundation static load detection technology is a static load test pile method in which the weight of the pile itself provides the reaction force without external force. During the construction process, the load box shaped according to the pile bearing capacity parameters is placed in the At the bottom of the pile body, connect the pressure oil pipe and the displacement measuring device to the top of the pile. After the concrete is cured to the standard age, pressurize the bottom load box through the top high-pressure oil pump to obtain the pile end bearing capacity and the total friction resistance of the pile side. At present, with the application and popularization of self-balancing pile foundation static load det...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02D33/00

CPCE02D33/00

Inventor 张自平符磊王磊冯校楠马良

Owner ZHEJIANG OUGAN MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com