Patents

Literature

69results about How to "Improve production and installation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

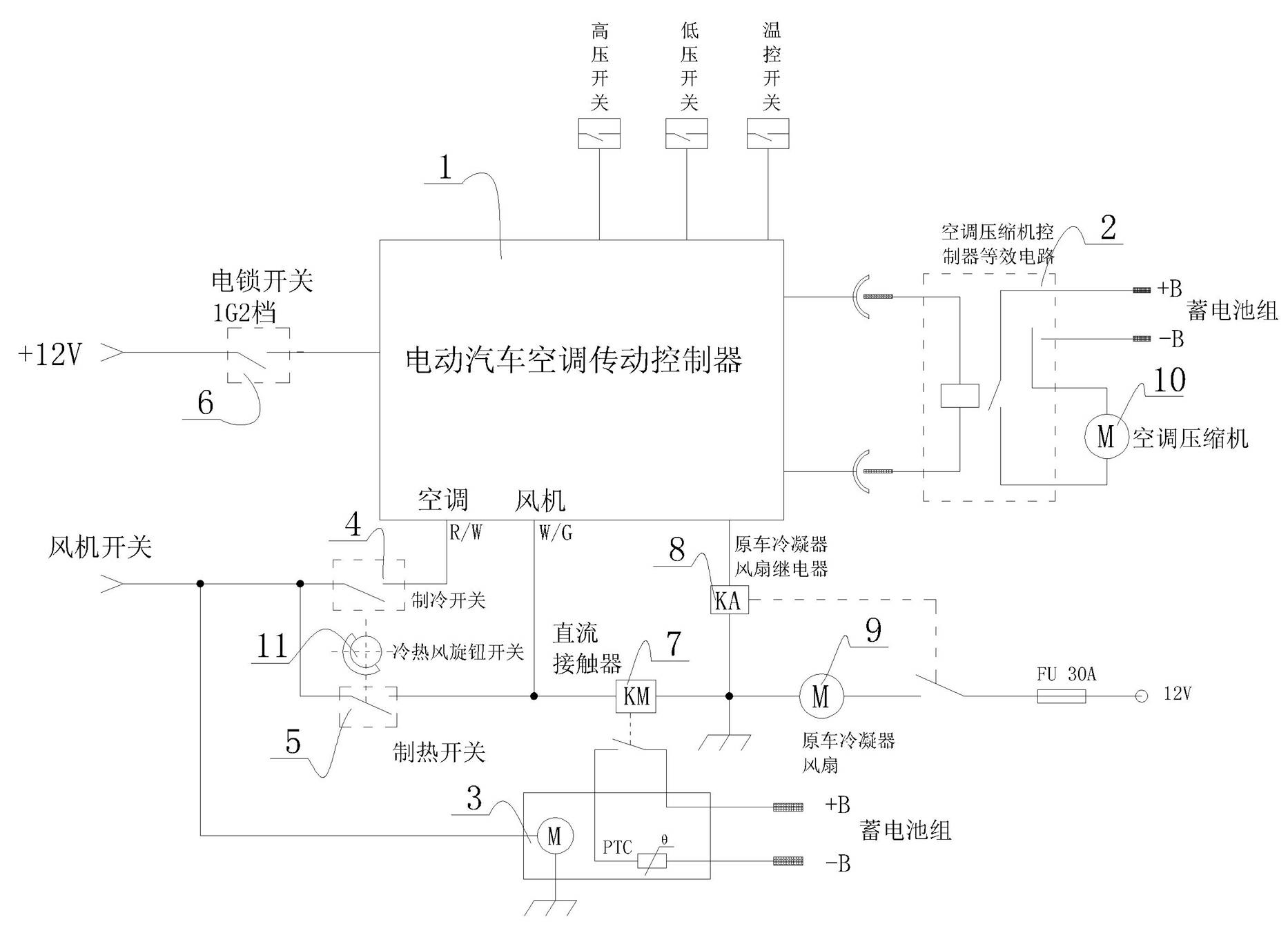

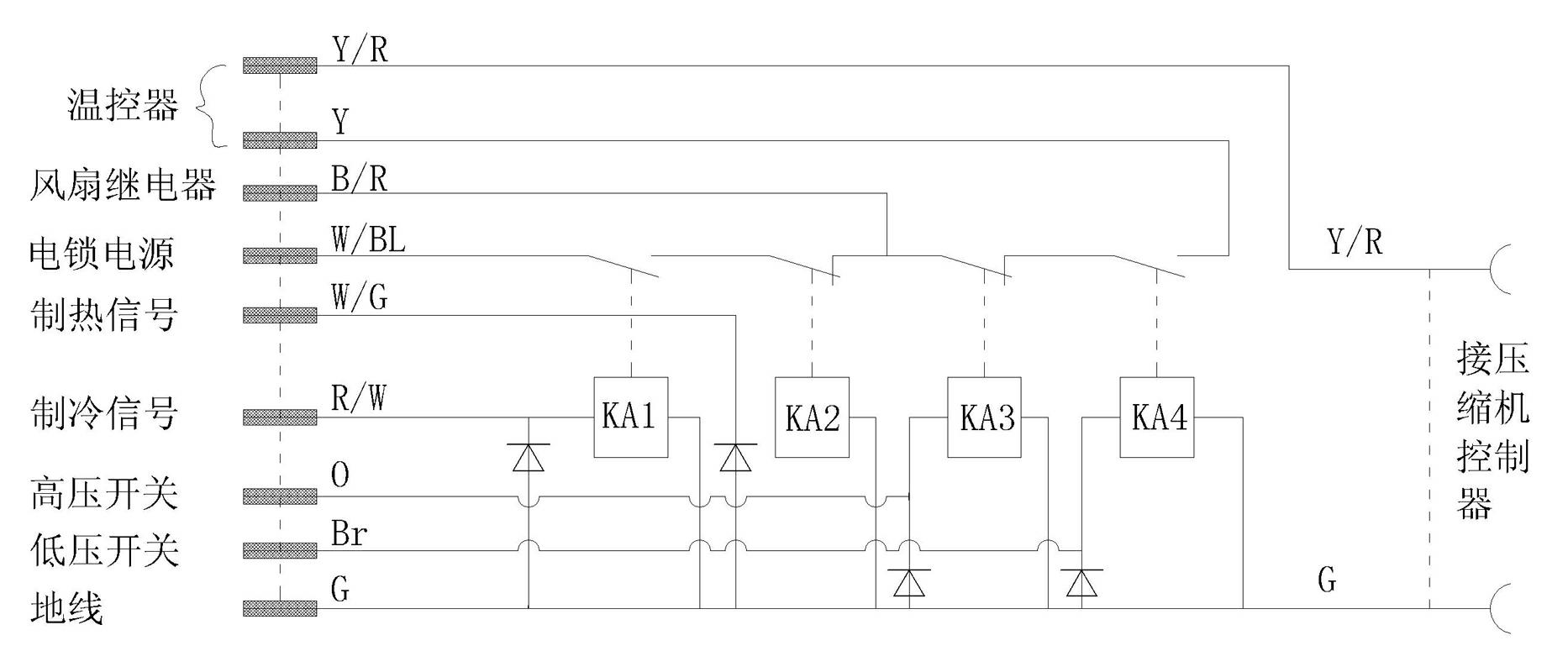

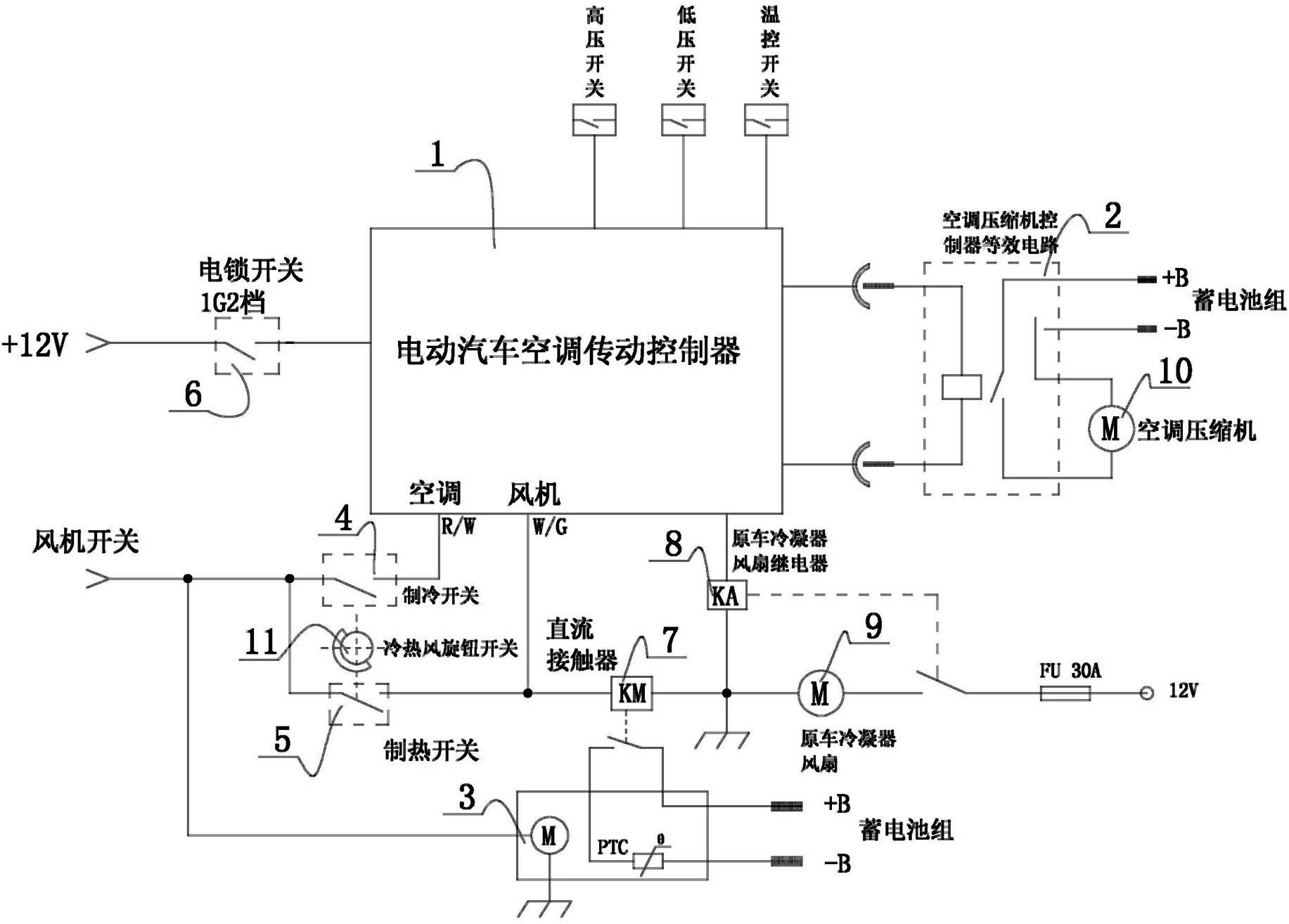

Air conditioning control system for electric vehicles

ActiveCN102278807AEffective controlEffective interlock controlSpace heating and ventilation safety systemsLighting and heating apparatusRotary switchControl system

The invention discloses an air-conditioning control system of an electromobile. The control system comprises an air-conditioning compressor, a blower assembly, a transmission controller and a storage battery, and is characterized in that a heating circuit comprises a heating switch, a direct current contactor and a heating element, wherein the heating switch is controlled by a cold-hot air rotary switch; the heating switch, the coil of the direct current contactor and a fan switch are connected in series and then are connected between a power supply and an earth wire; and the heating element and a normally open point of the direct current contactor are connected in series and then are connected to two ends of the storage battery. According to the invention, the match and combination of a special compression system of the electromobile and an original air-conditioning system of a common automobile are completed, and the control on an air-conditioning refrigeration system is finished effectively; simultaneously a PTC (positive temperature coefficient) heating body is adopted, and the perfect refrigeration and heating functions are realized; the control system is used for a pure electromobile which is obtained by modifying the common automobile, the design of a circuit is simplified greatly, the control system is convenient to install and use, and the modification efficiency of the electromobile can be improved greatly; and the control system has the characteristics of simple structure, low cost, safety and reliability, and is convenient to use and install.

Owner:山东宝雅新能源汽车有限公司

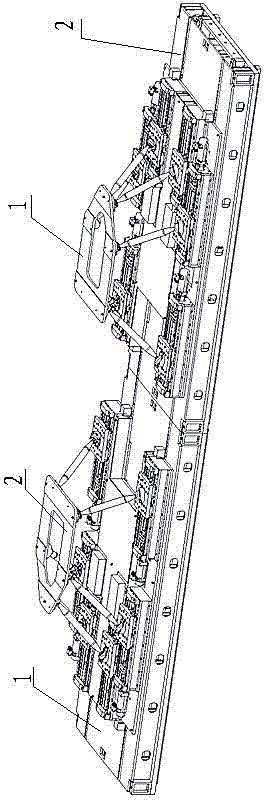

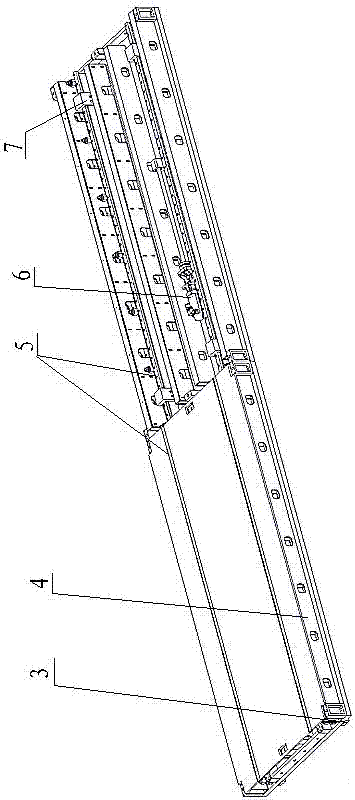

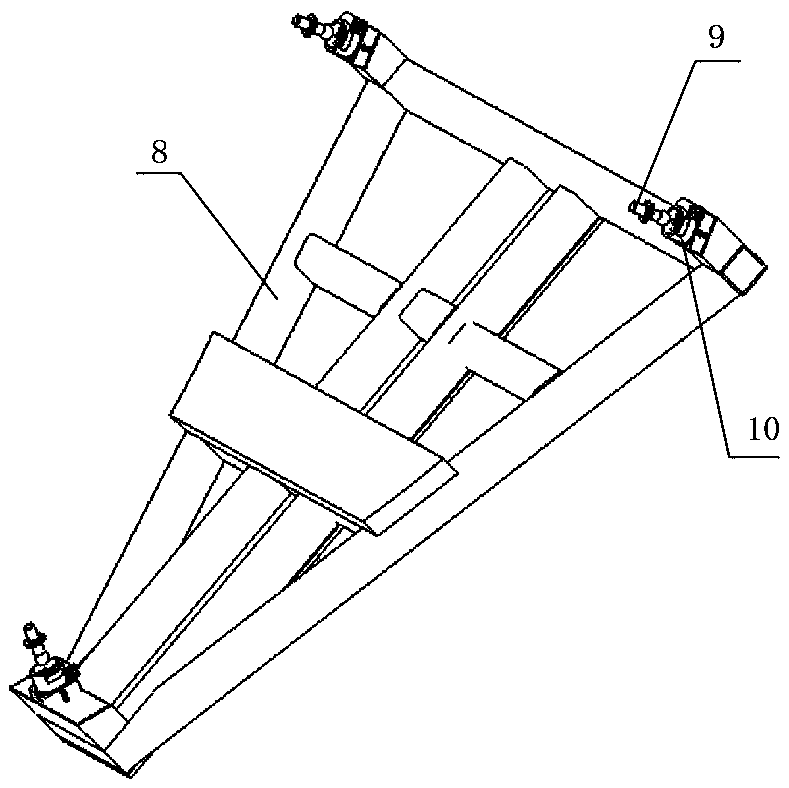

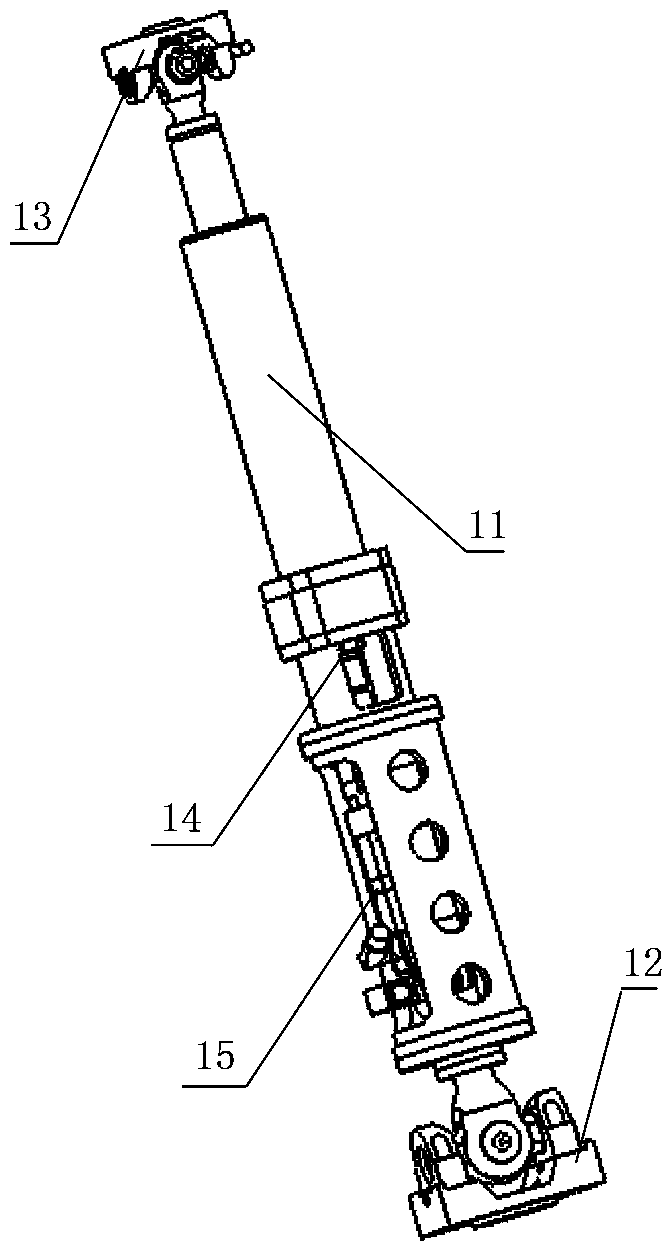

Six-freedom-degree airplane large component digital assembling parallel robot system

PendingCN107009351AQuick assemblyReduce workloadProgramme-controlled manipulatorRobotic systemsControl theory

A six-freedom-degree airplane large component digital assembling parallel robot system comprises two fixed base assemblies and two parallel movable platform assemblies. Each base is provided with an X-axis linear guide rail and an X-axis servo drive system connected with a base plate, wherein the lower portion of the base plate is provided with an X-axis guide rail sliding block matched with the X-axis linear guide rail. Each base plate is provided with at least three supporting bases. Each supporting base is provided with an X1-axis linear guide rail. The upper portion of each supporting base is provided with a spherical hinge supporting base capable of sliding along the corresponding X1-axis linear guide rail. Each spherical hinge supporting base is provided with a lower spherical hinge connected with the lower end of a supporting rod. The upper ends of the supporting rods are connected with upper spherical hinges arranged on the lower sides of posture adjusting platforms. Each supporting base is connected with one X-axis servo drive system. By means of the six-freedom-degree airplane large component digital assembling parallel robot system, it is guaranteed that high-precision positioning and reliable and accurate butt joint assembling of large space components on the system can be achieved; and the problems that in the traditional technology, long-stroke high-precision assembling adaptability is poor, cost is high, the assembling efficiency is low, and the management difficulty is large are solved.

Owner:大连四达高技术发展有限公司

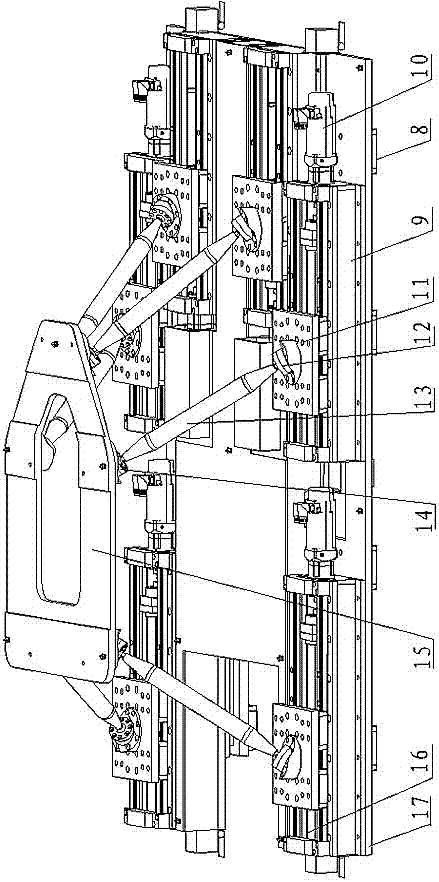

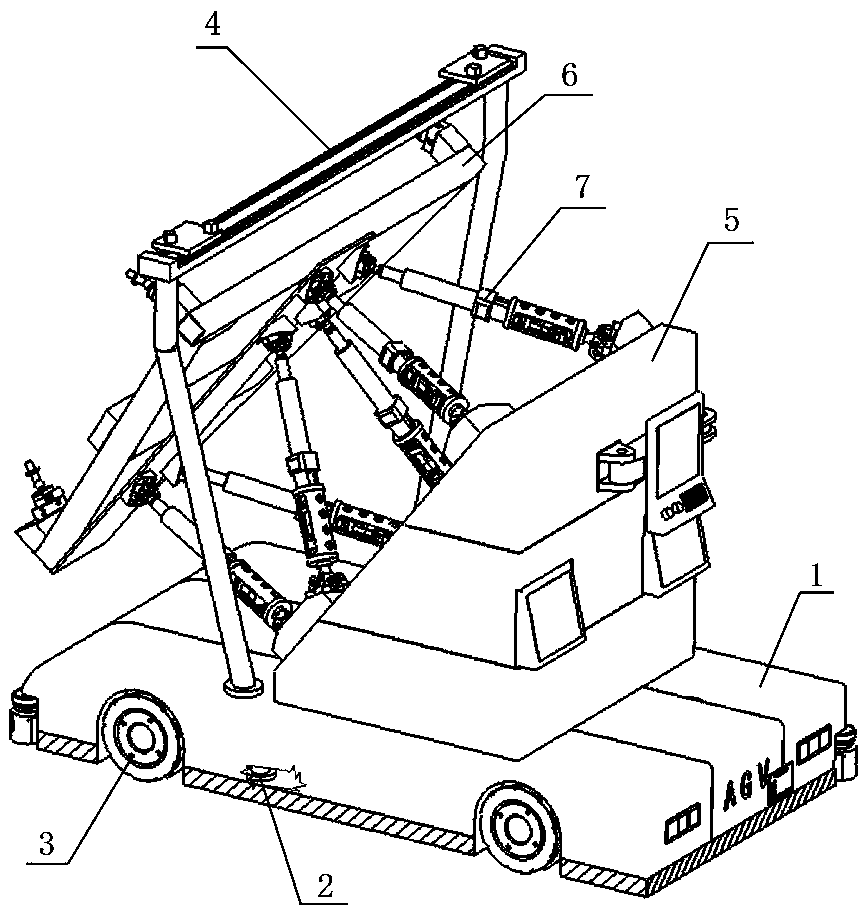

Airplane cabin door intelligent installation method based on AGV intelligent parallel robot

ActiveCN108620840AMeet the requirements of the assembly siteReduce occupancyAircraft componentsProgramme-controlled manipulatorAviationSimulation

The invention discloses an airplane cabin door intelligent installation method based on an AGV intelligent parallel robot. According to the airplane cabin door intelligent installation method based onthe AGV intelligent parallel robot, the AGV intelligent movement robot is used in cooperation a six-degree-of-freedom platform and a binocular vision system, and a technological method of multi-axisposture alignment and accurate installation operation of an airplane cabin door or a light intermediate part is changed. Aiming at installation of the airplane cabin door, the invention discloses theAGV intelligent parallel robot matched with the method. The robot is creatively designed in the aspects of the integral structure, the linkage manner between an AGV body and a parallel platform, the structure of the parallel platform and the like, and can achieve automatic and intelligent installation of the airplane cabin door. Compared with a traditionally manual or semiautomatic installation technology, the accuracy, the efficiency and the safety of cabin door installation are remarkably improved, the number of workers, the labor intensity and the requirement for skills are greatly reduced,and the method and the robot represent the trend that nowadays, the aeronautic equipment manufacturing industry develops in the direction of digitization, automation and intelligence.

Owner:大连四达高技术发展有限公司

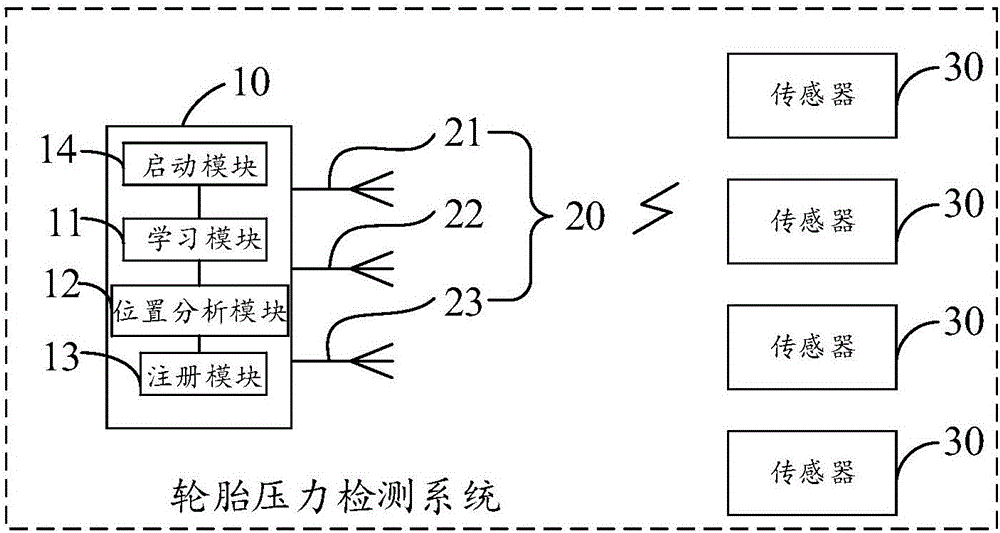

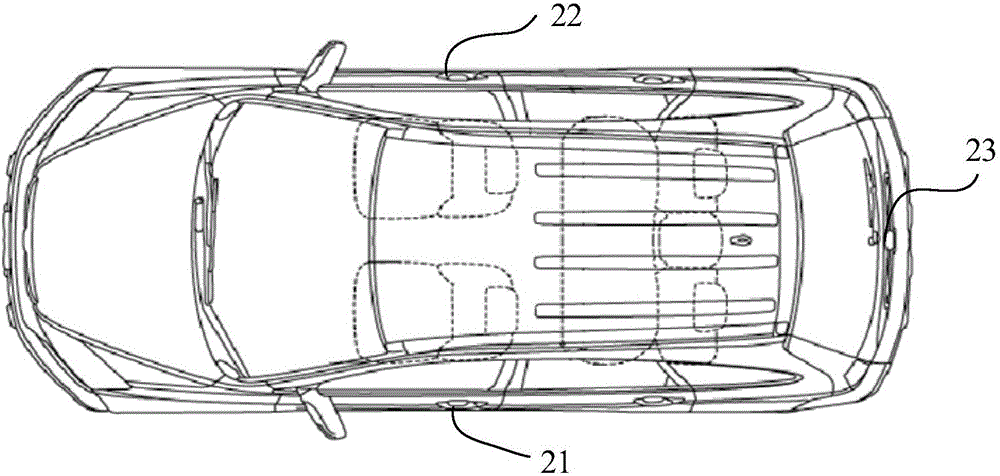

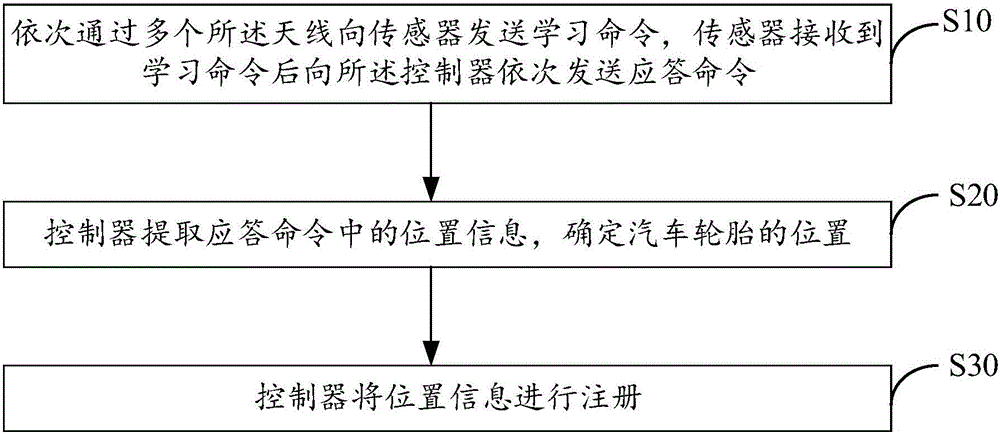

Tire automatic matching method and tire pressure detection system

InactiveCN105751833AImprove production and installation efficiencyTyre measurementsEngineeringTire pressure

The invention discloses a tire automatic matching method and a tire pressure detection system. The tire automatic matching method comprises the following steps: sending learning commands to a sensor through a plurality of antennas in sequence; after the sensor receives the learning commands, sending answering commands to a controller in sequence; extracting position information in the answering commands through the controller and determining the position of an automobile tire; and registering the position information through the controller. With the adoption of the technical scheme, the production and installation efficiency of an automobile is improved.

Owner:CLOUDATLAS ELECTRONICS EQUIP SYST CO LTD

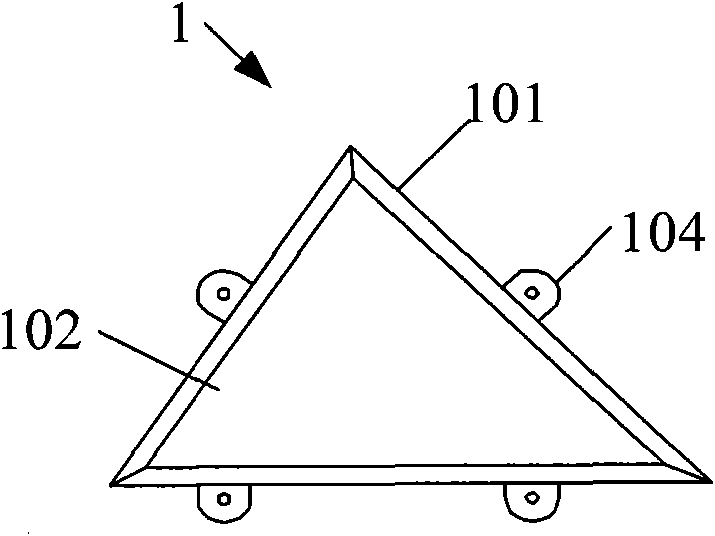

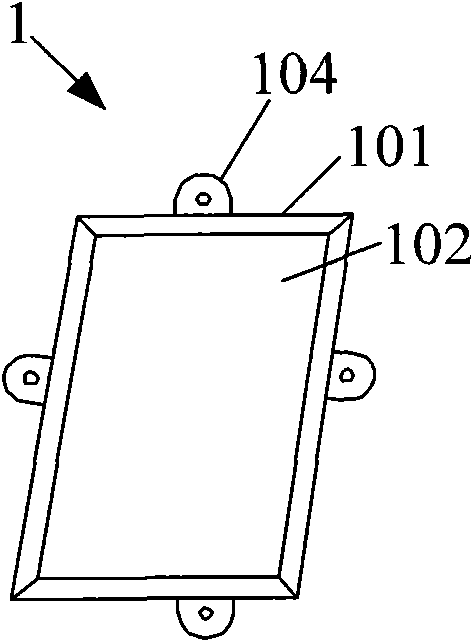

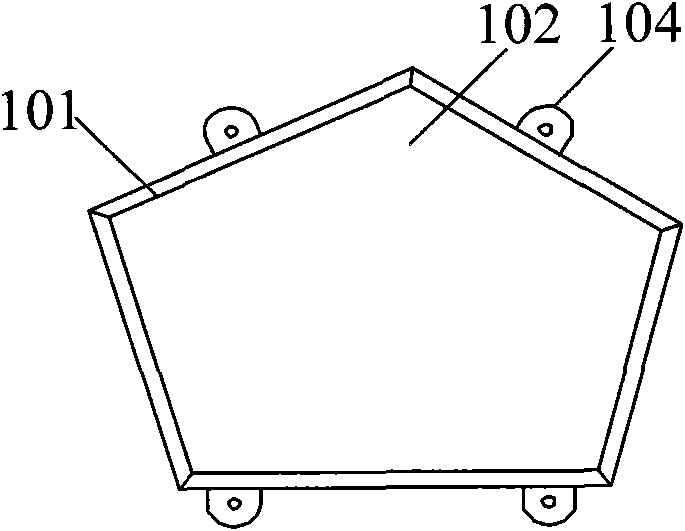

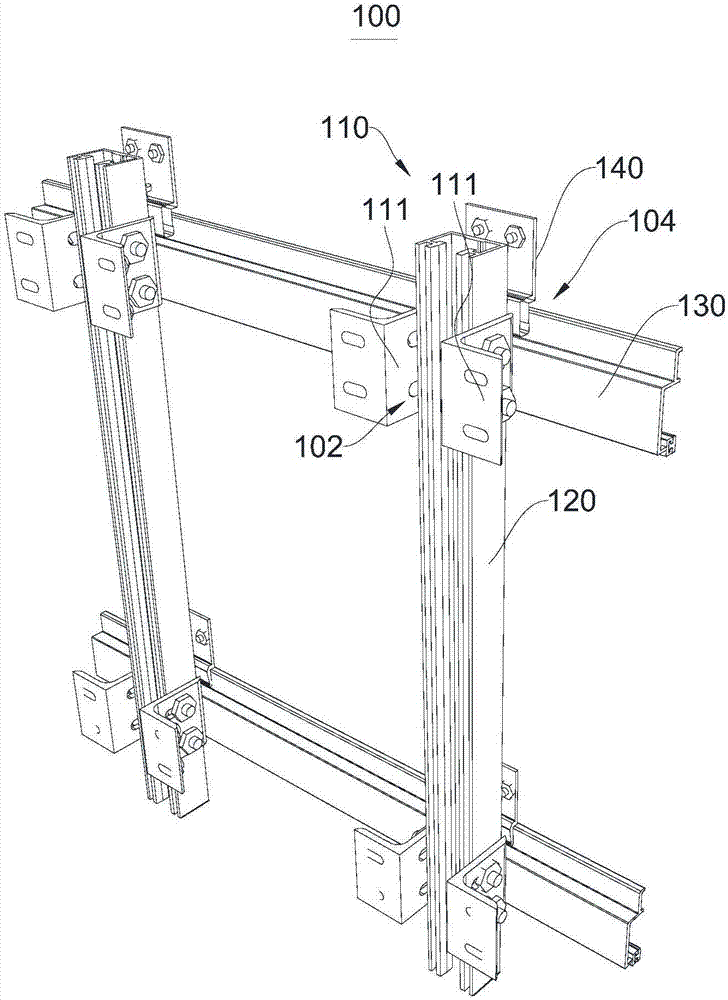

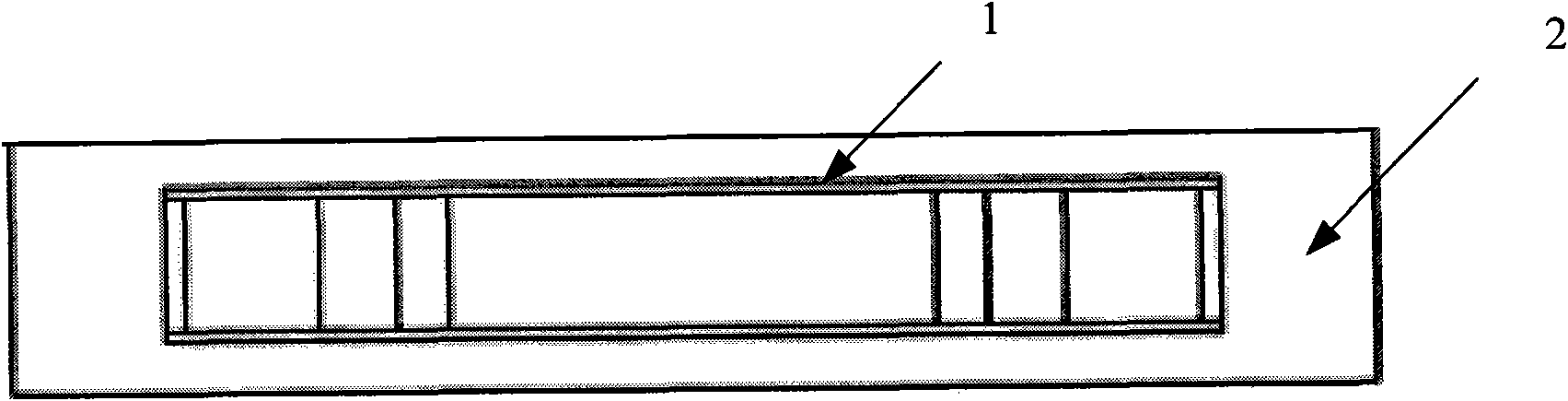

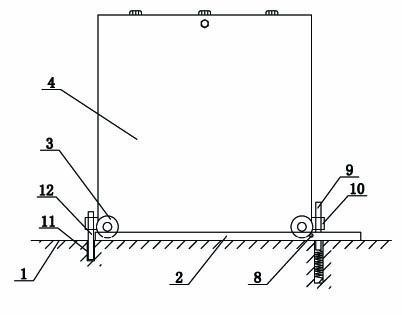

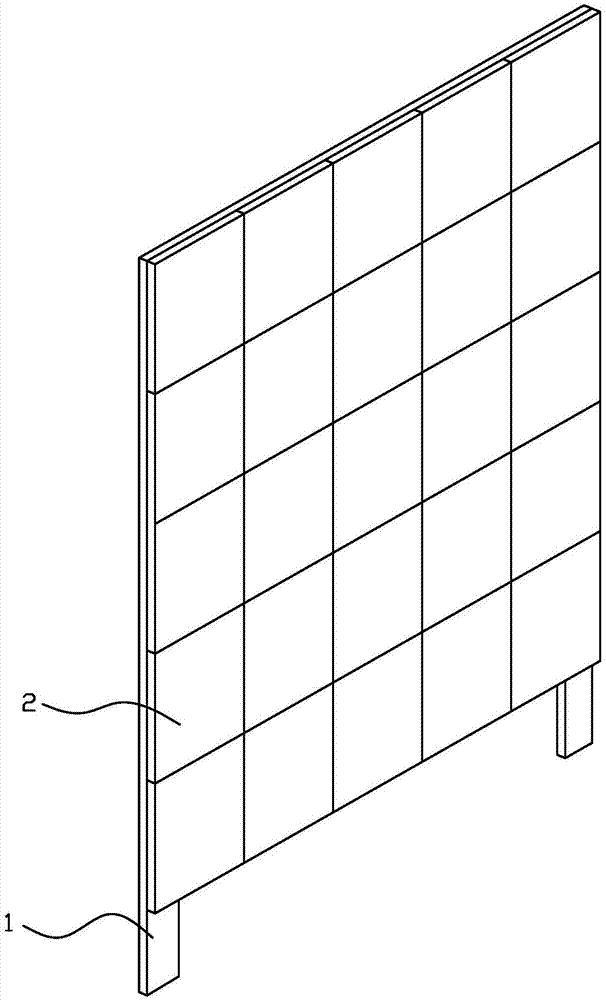

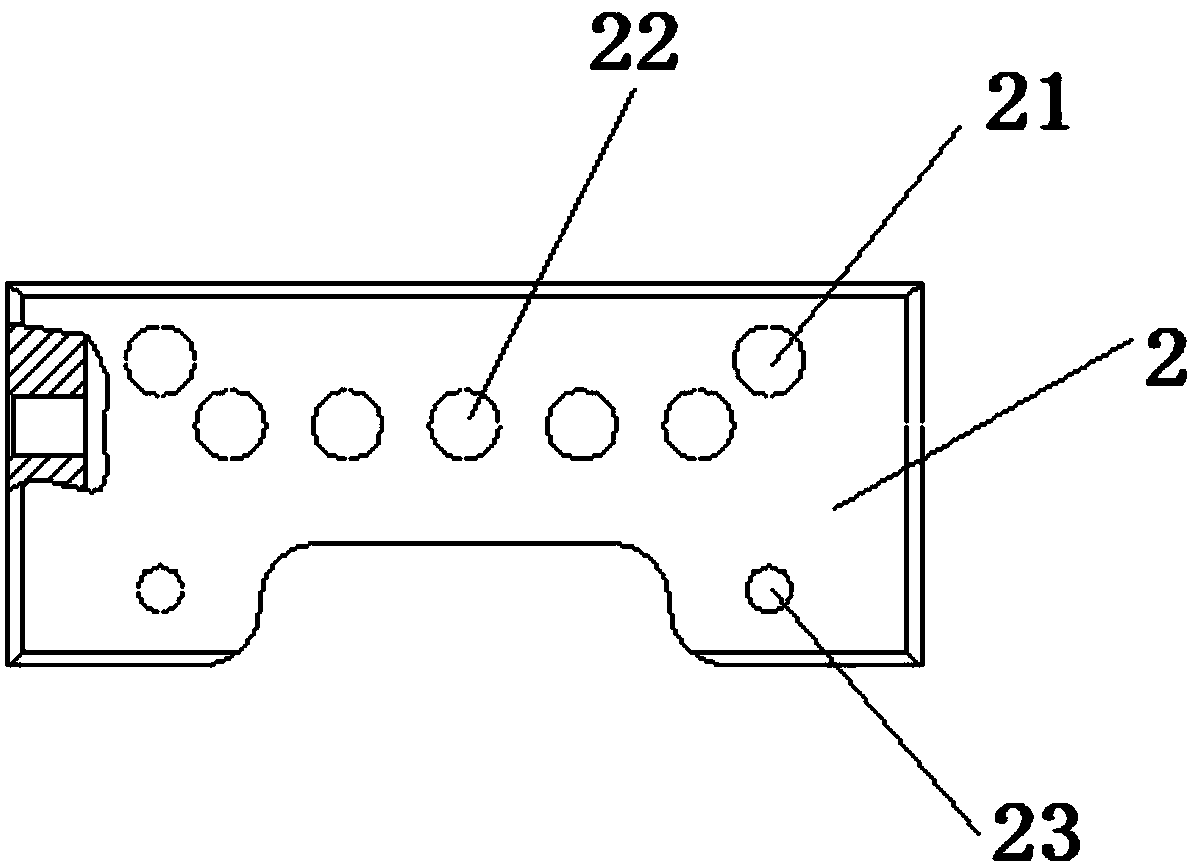

Building curtain wall component and spliced building curtain wall thereof

ActiveCN102312493AVarious shapesImprove production and installation efficiencyCovering/liningsWallsGeometric frameworkArchitectural engineering

The invention discloses a building curtain wall component which comprises a plurality of frameworks and at least one panel. The frameworks are welded into a geometric framework component and the panel and the framework component are connected into a whole. The invention also discloses a spliced building curtain wall which is formed by splicing a plurality of the building curtain wall components. The spliced building curtain wall formed by assembling the building curtain wall components provided by the invention has diversity. The whole building curtain wall is formed by the building curtain wall components. By adopting a processing method for welding a component type spliced building curtain wall, componentization and factory production can be realized, and the spliced effect of the outervertical surface of a building is ensured.

Owner:SHANGHAI JANGHO CURTAIN WALL SYST ENG +2

Dry hang structure and decorative finish system

PendingCN107327111AEasy to disassembleImprove production and installation efficiencyCovering/liningsKeelMaterial resources

The invention relates to the field of buildings, and discloses a dry hang structure and a decorative finish system. The dry hang structure comprises at least one first keel, at least one second keel, a connecting part used for fixedly connecting the first keel and the wall and a hanging buckling member used for connecting the second keel and a decorative finish plate. The first keel is connected to the wall through the connecting part; the second keel is detachably connected to the first keel through a second fastening piece, and after the hanging buckling piece is fixed to the decorative finish plate which needs to be installed, and is connected to the second keel, and hanging of the decorative finish plate is completed. The dry hang structure enables staff to conduct combining and assembling in a field, the installation efficiency is improved, a large amount of labor and material resources for conducting positioning, base layer manufacturing and hanging strip fireproof brushing treatment are saved, and the manual cost is lowered. The dry hang structure also facilitates dismantling of the decorative finish plate, and the damage to the decorative finish plate or the dry hang structure is small; when part of the decorative finish plate is damaged, the decorative finish plate is convenient to replace.

Owner:GOLD MANTIS CONSTR DECORATION

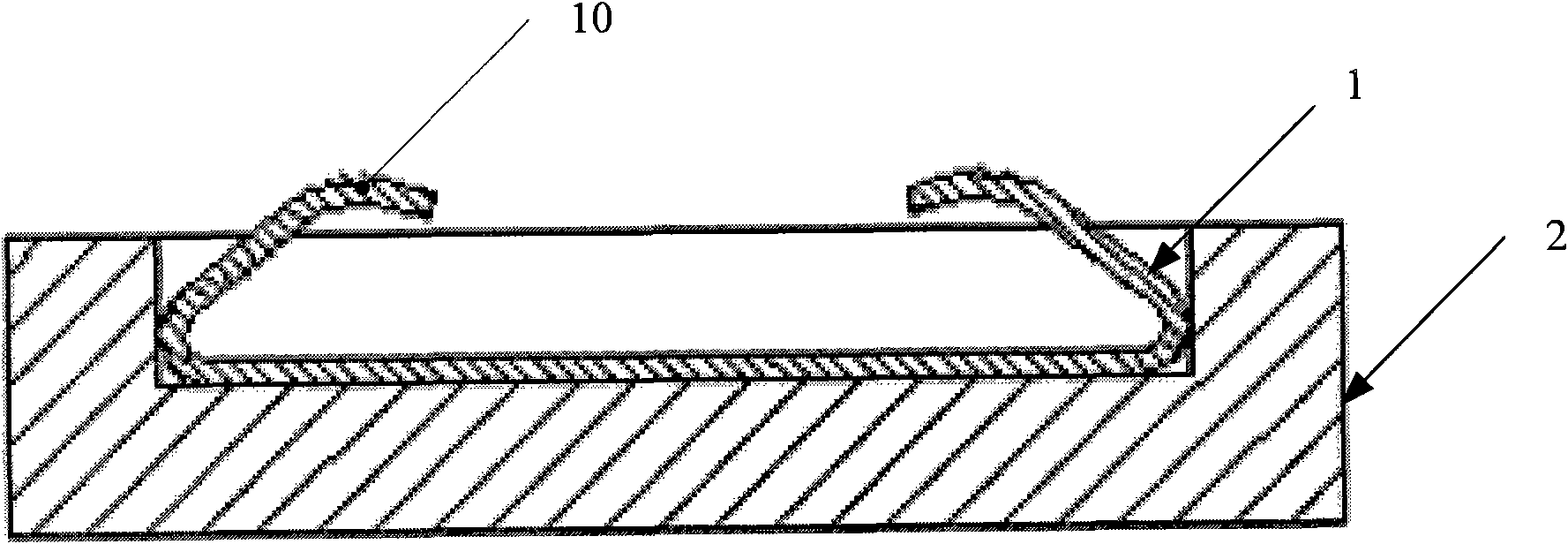

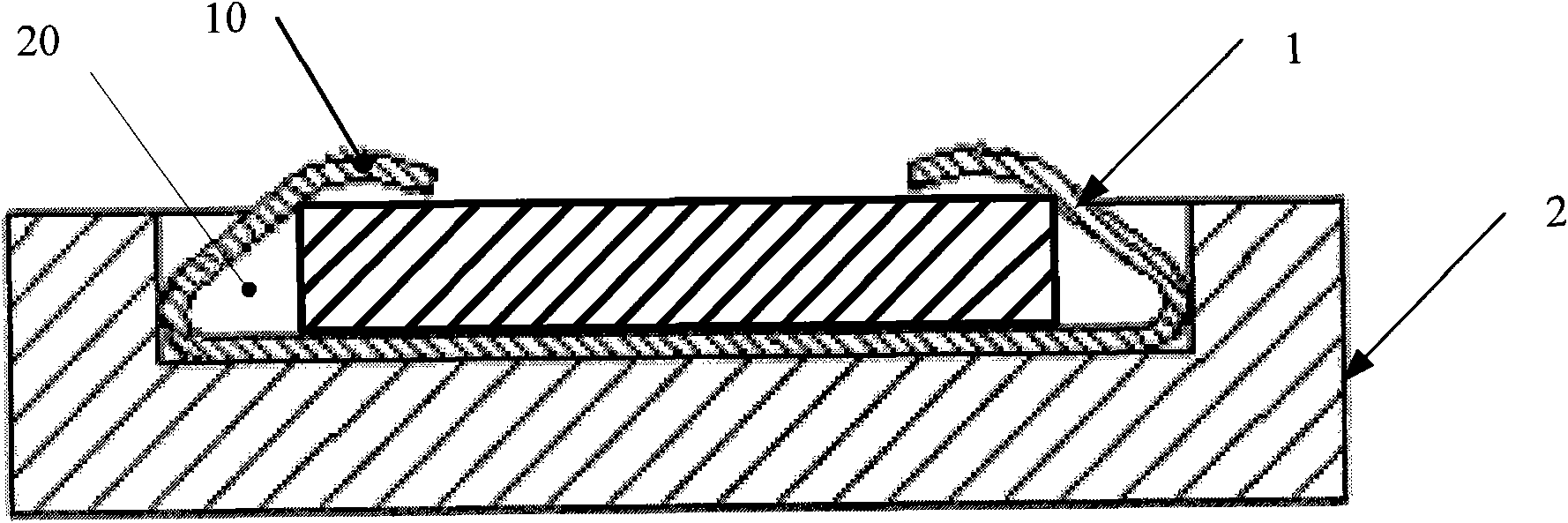

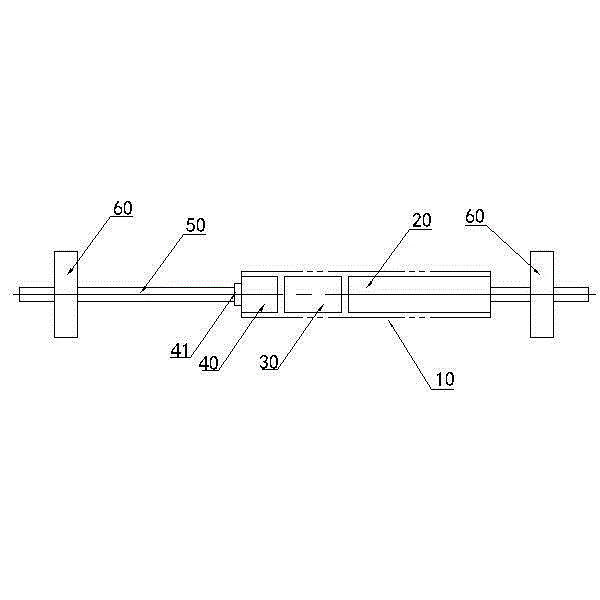

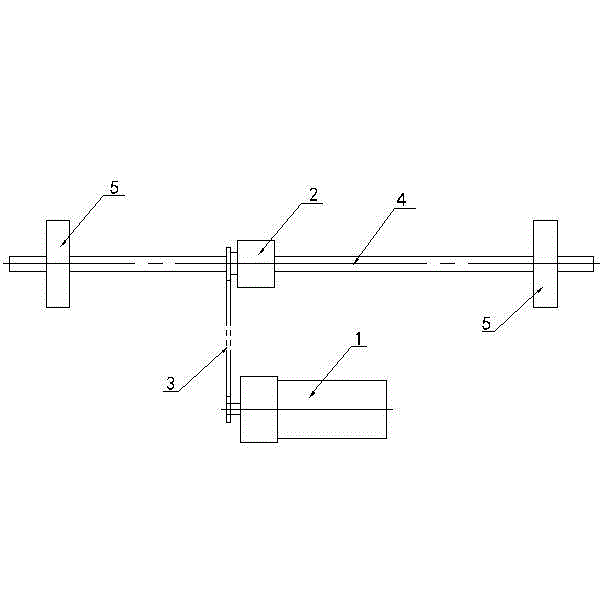

Connector among plates and electronic device

InactiveCN101685913AImprove production and installation efficiencyImprove consistencyCoupling contact membersClamped/spring connectionsElectronic circuitSingle plate

The invention discloses a connector among plates and an electronic device, belonging to the field of electronic circuits. The connector among plates comprises a metal elastic connecting body and a sleeve member, wherein the metal elastic connecting body comprises at least two mutually connected pins; the pins are respectively connected with a plurality of veneers; and the metal elastic connectingbody is placed in the sleeve member. The electronic device comprises the connector among plates. The invention has the advantages of high efficiencies of production and installation and good consistency of radio frequency signals.

Owner:HUAWEI TECH CO LTD

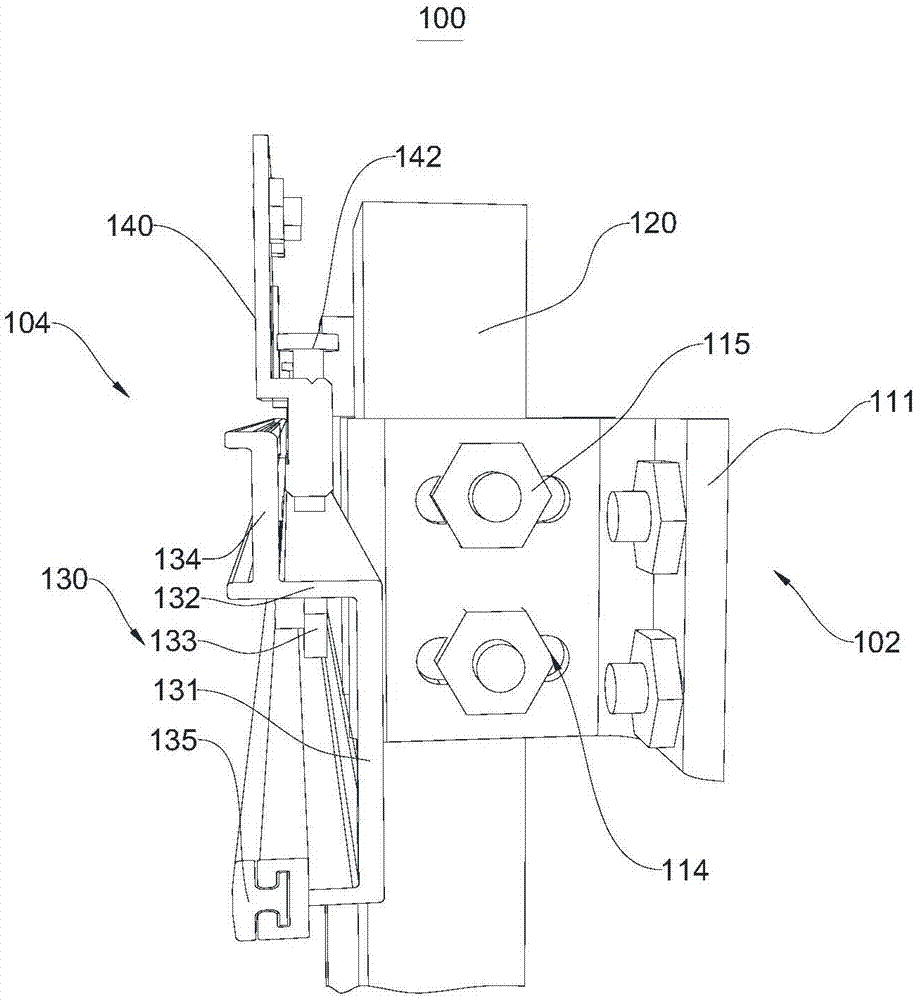

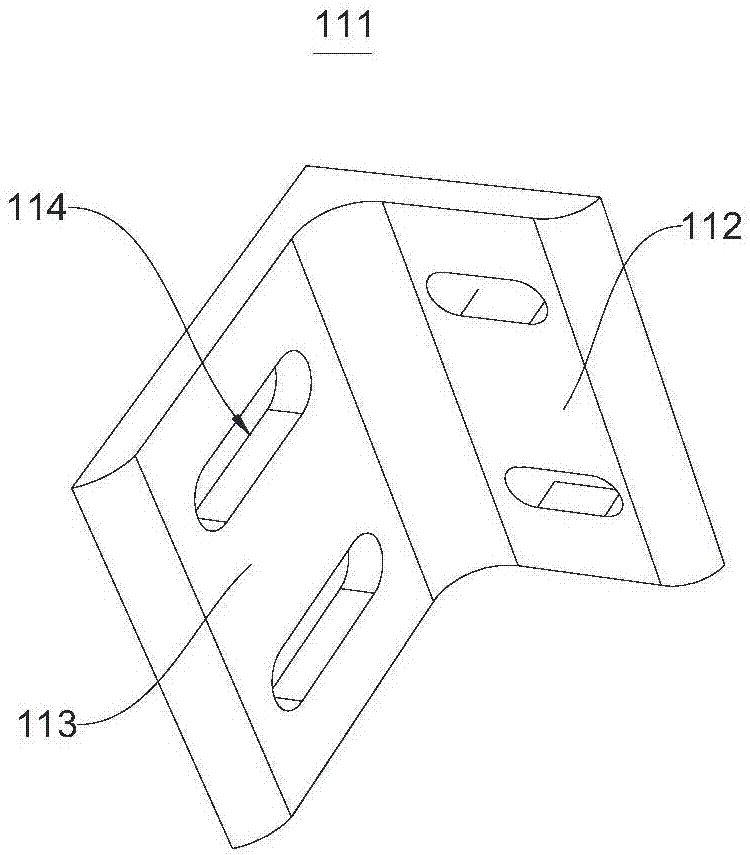

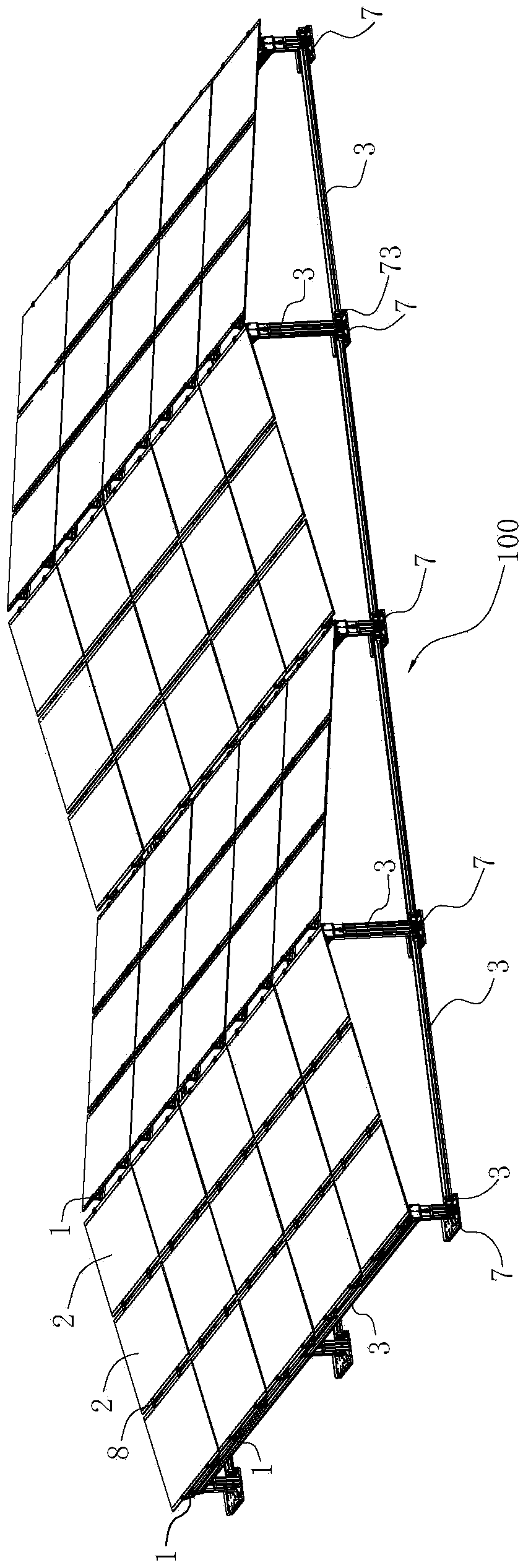

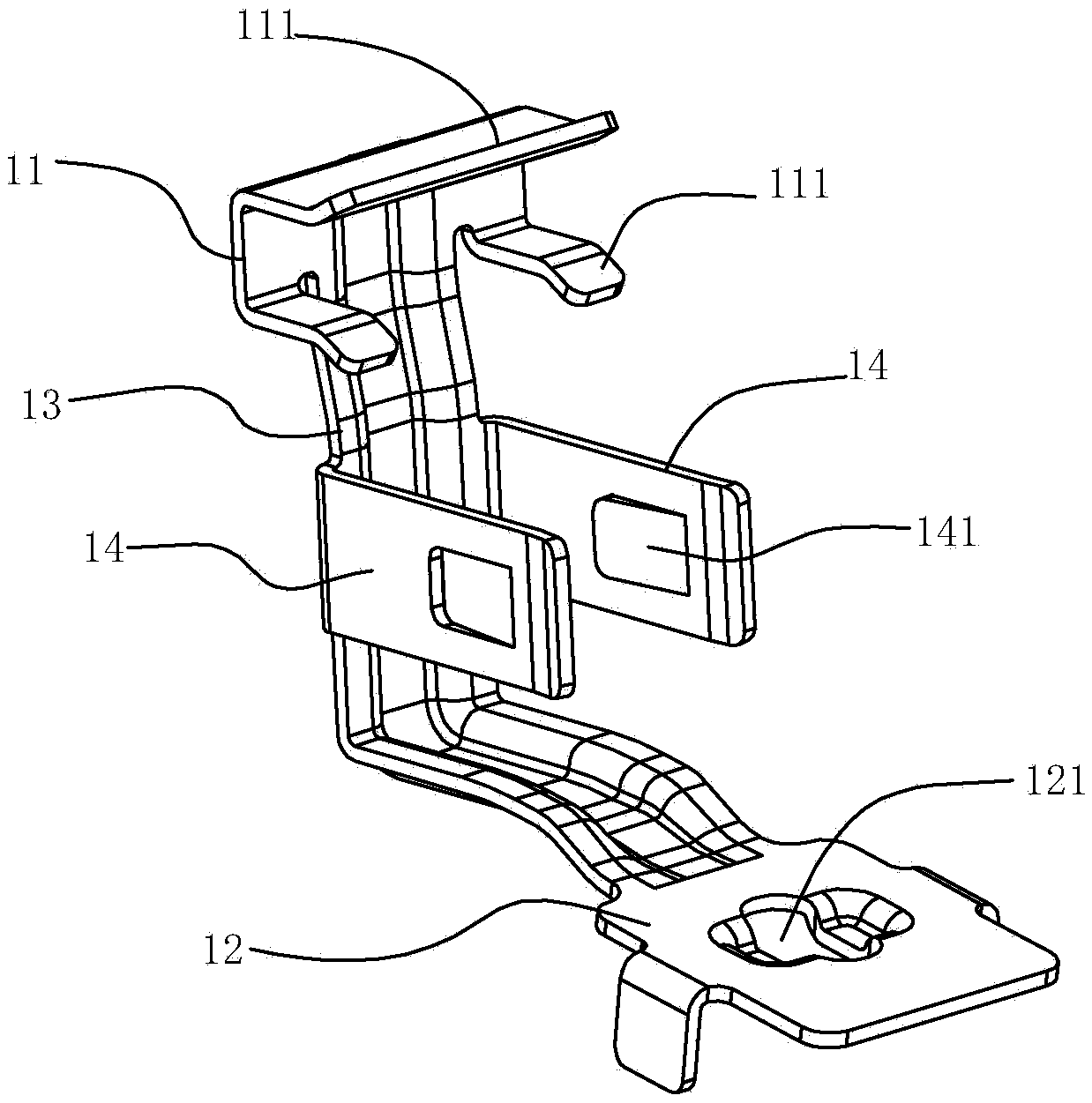

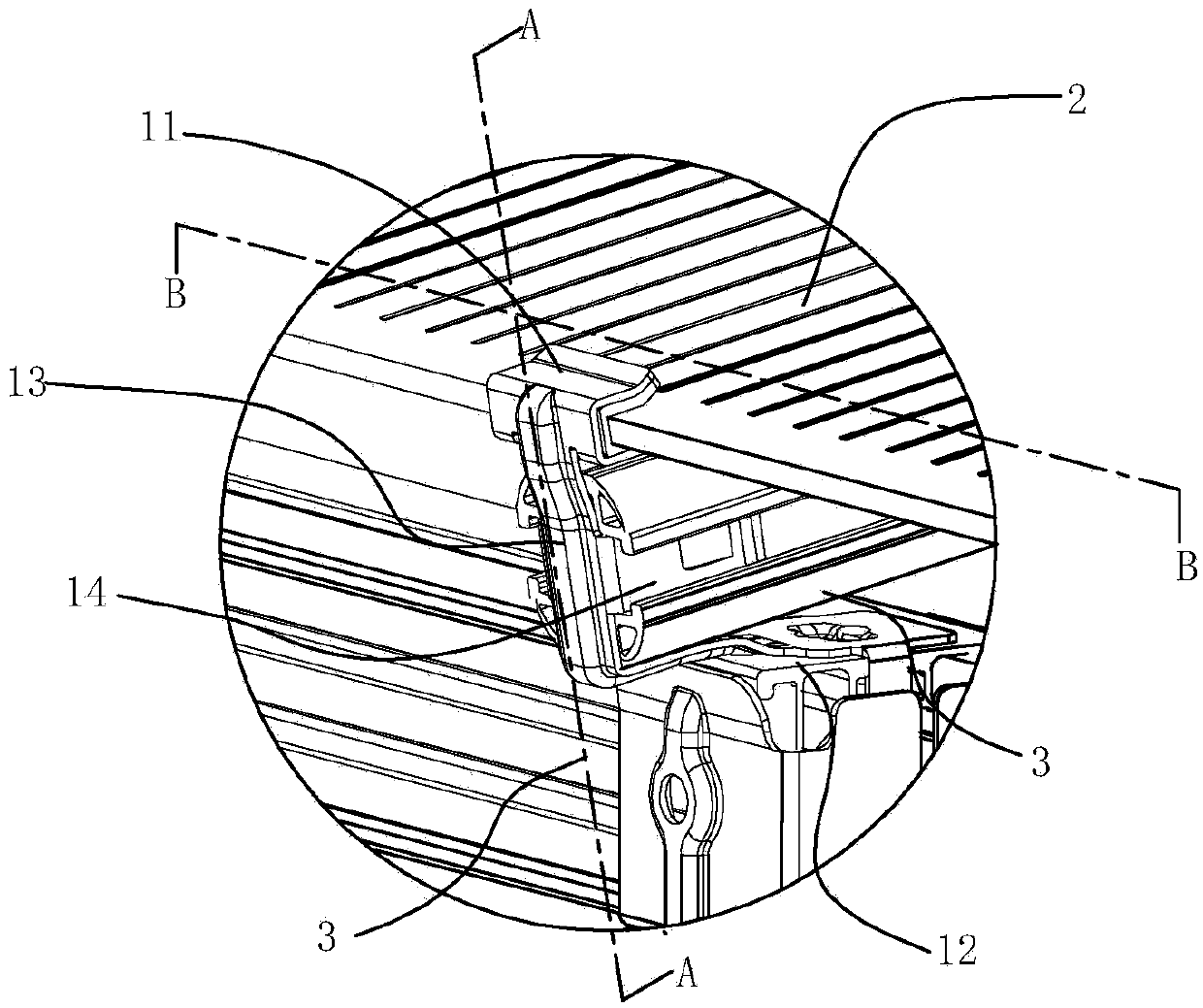

Connecting piece and solar panel installation support with same

ActiveCN105375868AEasy to install and disassembleImprove connection strengthPhotovoltaic supportsPhotovoltaic energy generationEngineeringElectrical and Electronics engineering

Owner:NINGBO DAZHI MACHINE TECH CO LTD

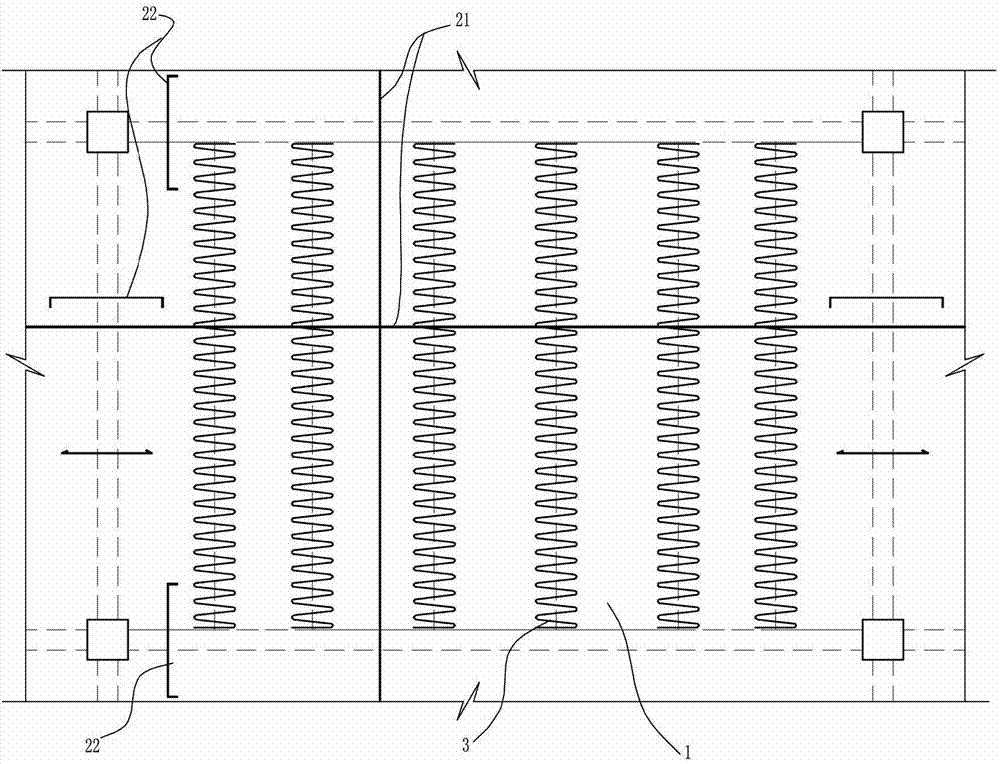

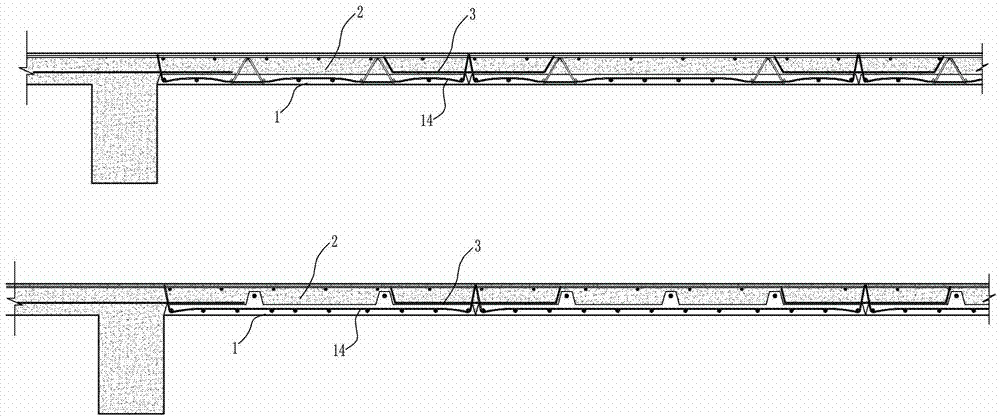

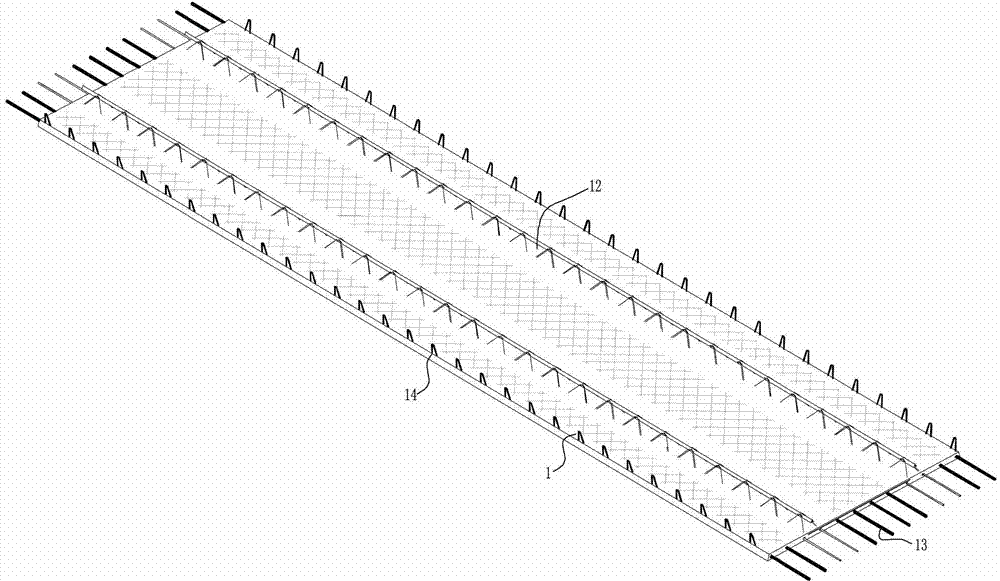

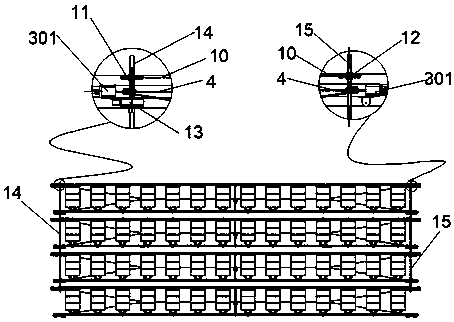

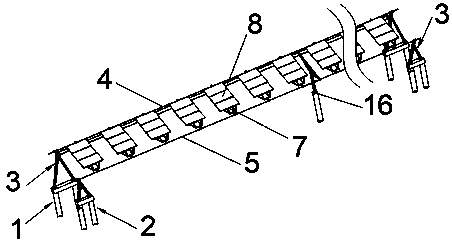

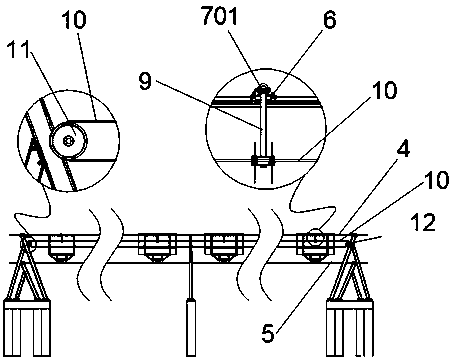

Lap joint bar type prestressed two-way laminated plate and construction method

The invention provides a lap joint bar type prestressed two-way laminated plate which comprises at least three prefabricated prestressed thin plates, a rear pouring concrete layer and a plate seam lap joint steel bar. The prefabricated prestressed thin plates are large-width plates with ribs and steel bar trusses, and the plate seam lap joint steel bar is S-shaped in continuous mode, stretches cross plate seams, is horizontally paved on the upper surfaces of the adjacent prefabricated thin plates, and is embedded in the rear pouring concrete layer. The prefabricated prestressed thin plates are small in thickness, light in self weight, high in two-way reinforcement strength, not prone to crack and large in transportation radius and facilitates amplification of service radius of products.

Owner:杨众 +1

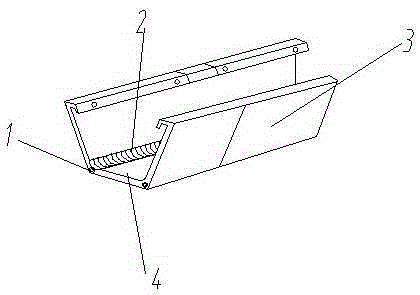

Rear-mounted energy storage device of electric automobile

InactiveCN102582405ASolve mobileEasy to fixElectric propulsion mountingStructural engineeringMechanical engineering

The invention relates to a rear-mounted energy storage device of an electric automobile, which comprises a trunk. A slide way is arranged on a bottom plate of the trunk, rollers are arranged on the slide way and connected with an energy storage box via roller shafts, a front slot is arranged at the bottom of the front end surface of the energy storage box, a front inserting plate corresponding to the front slot is disposed on the bottom plate of the trunk, a rear inserting plate is disposed at the bottom of the rear end surface of the energy storage box, a rear slot corresponding to the rear inserting plate is arranged on the bottom plate of the trunk, a storage battery is arranged in the energy storage box and fixed with the energy storage box via a pressure plate, one end of the pressure plate is hinged with the energy storage box, and the other end of the pressure plate is fixed with the energy storage box via a bolt. The energy storage box can be conveniently and fast fixed with the trunk of the automobile, simultaneously, the rollers are disposed at four bottom corners of the energy storage box, the slide way is arranged in the trunk of the automobile and matches with the rollers, so that the energy box can move, and the difficult problem that the storage battery of the electric automobile is detached and replaced difficultly is resolved.

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

Parallelism detection method for contact surfaces of sector plate of coiling machine

InactiveCN104215209AReduce difficultyImprove production and installation efficiencyMeasurement devicesDatum referenceEngineering

The invention relates to a parallelism detection method for contact surfaces of a sector plate of a coiling machine. A benchmark reference plane is set, after the sector plate is mounted at one step, the parallelism between each contact surface of the sector plate and the benchmark reference plane is detected, and the sector plate is mounted after all the contact surfaces are determined to be parallel, so that repeated assembly, detection and polishing is not required, difficulty in parallelism detection of the contact surfaces of the sector plate is lowered greatly, and production and mounting efficiency is improved.

Owner:宝钢苏冶重工有限公司

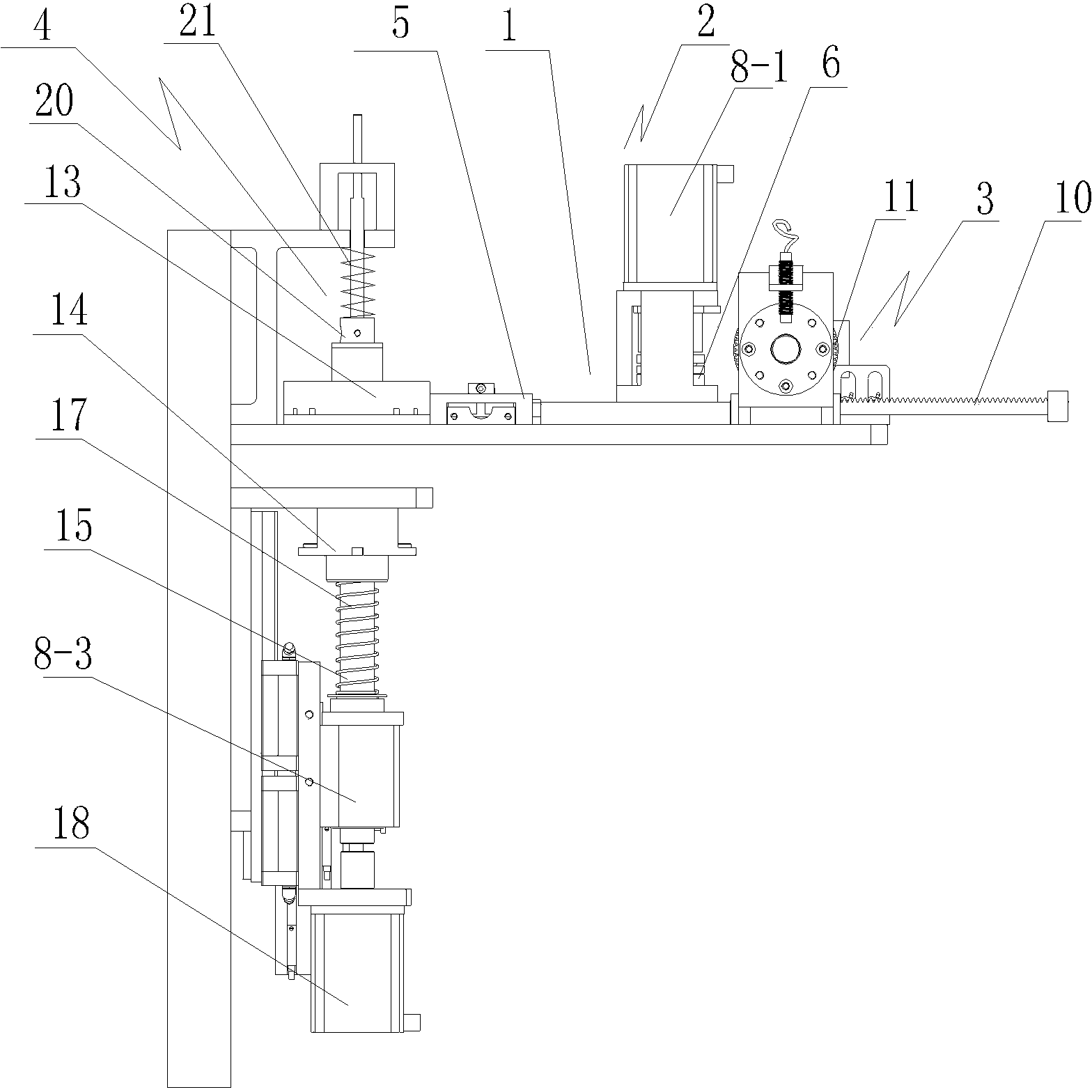

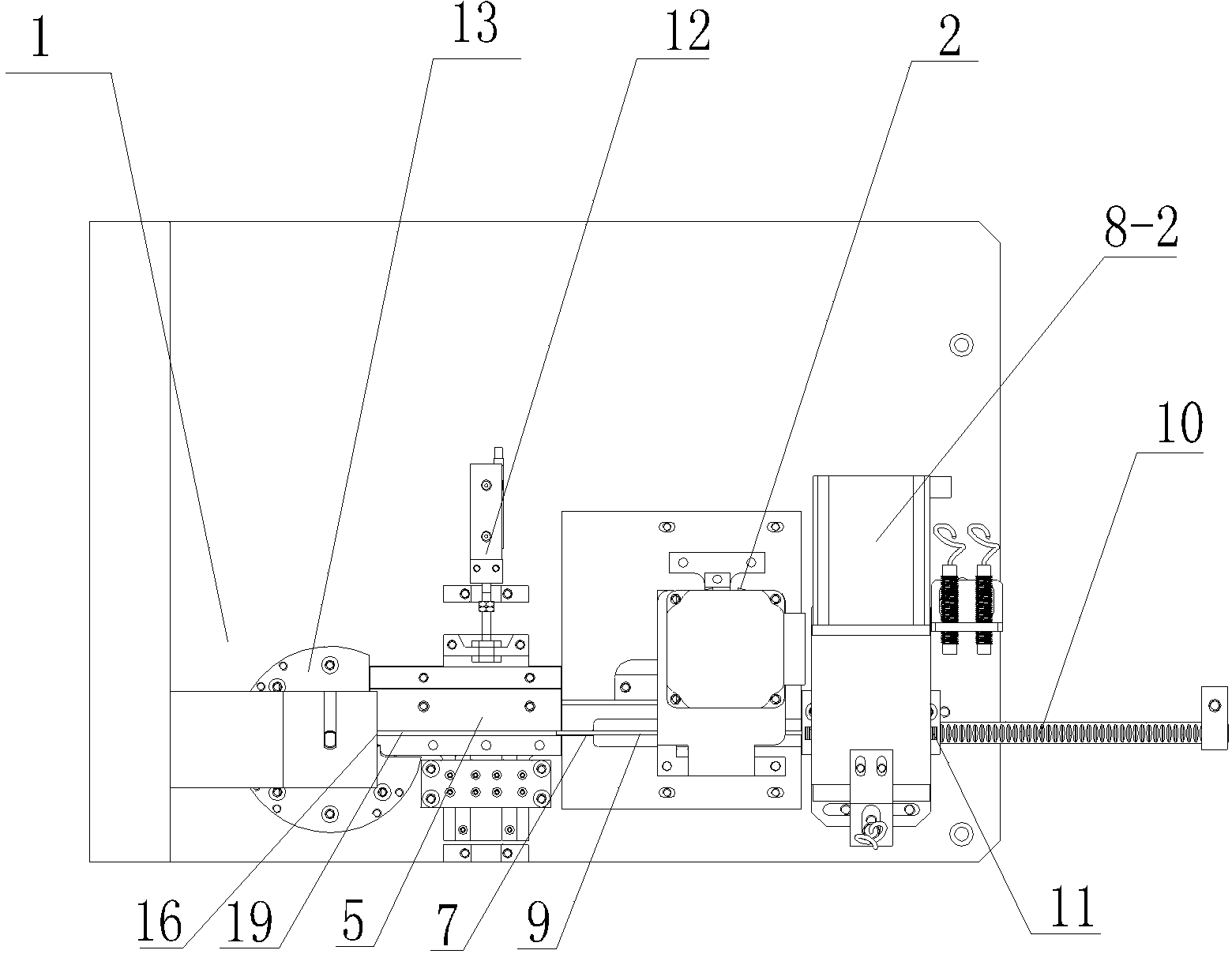

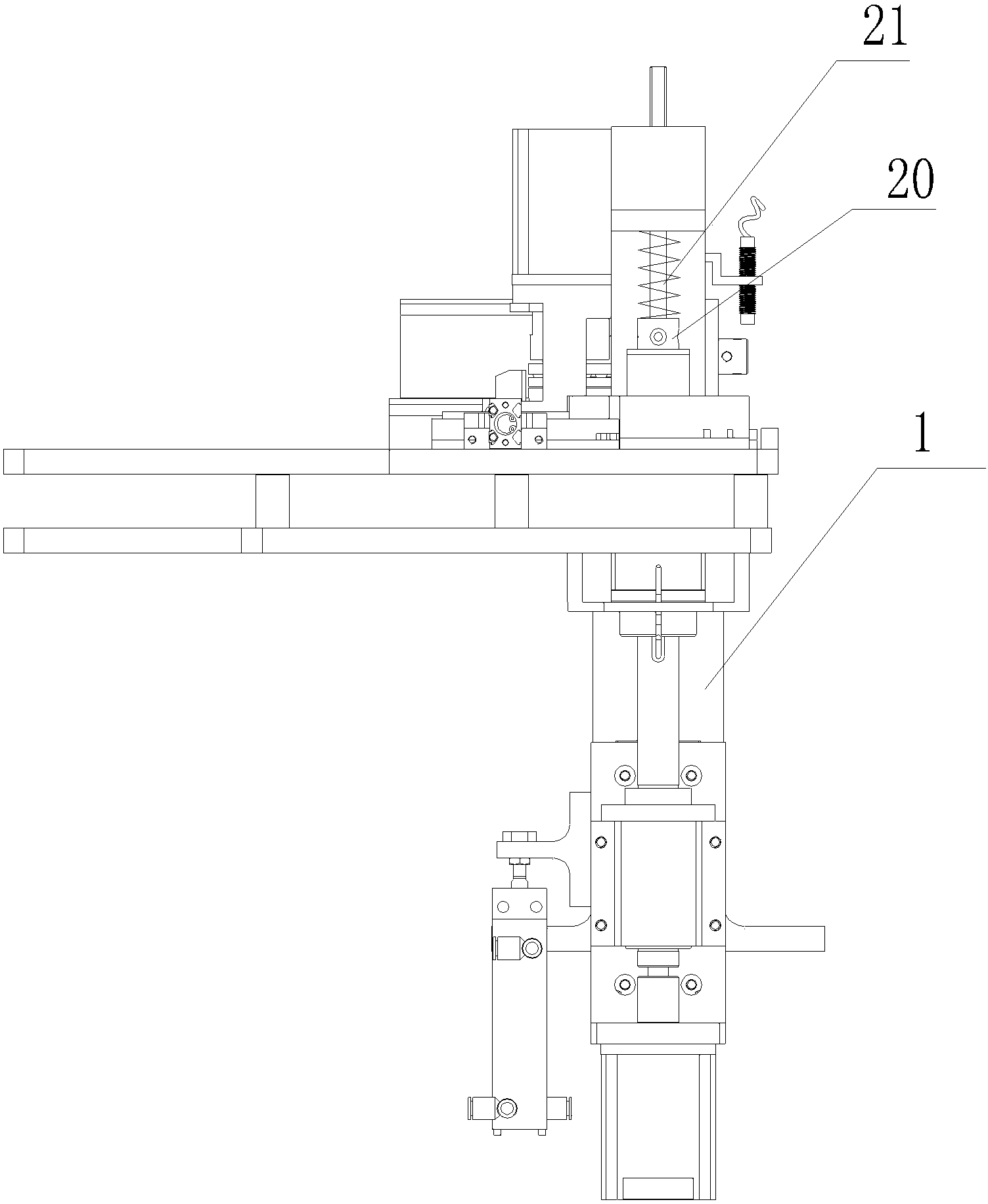

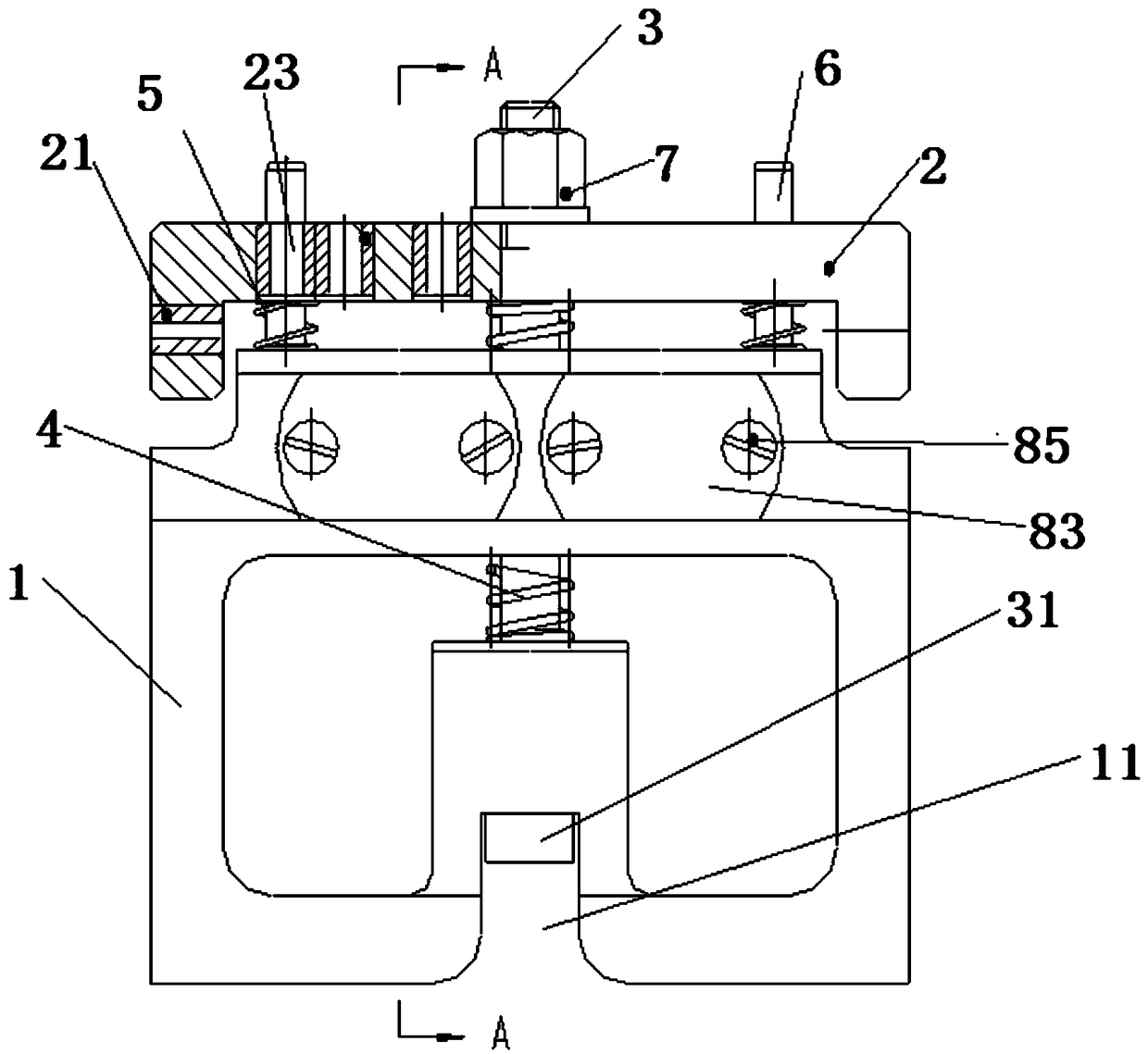

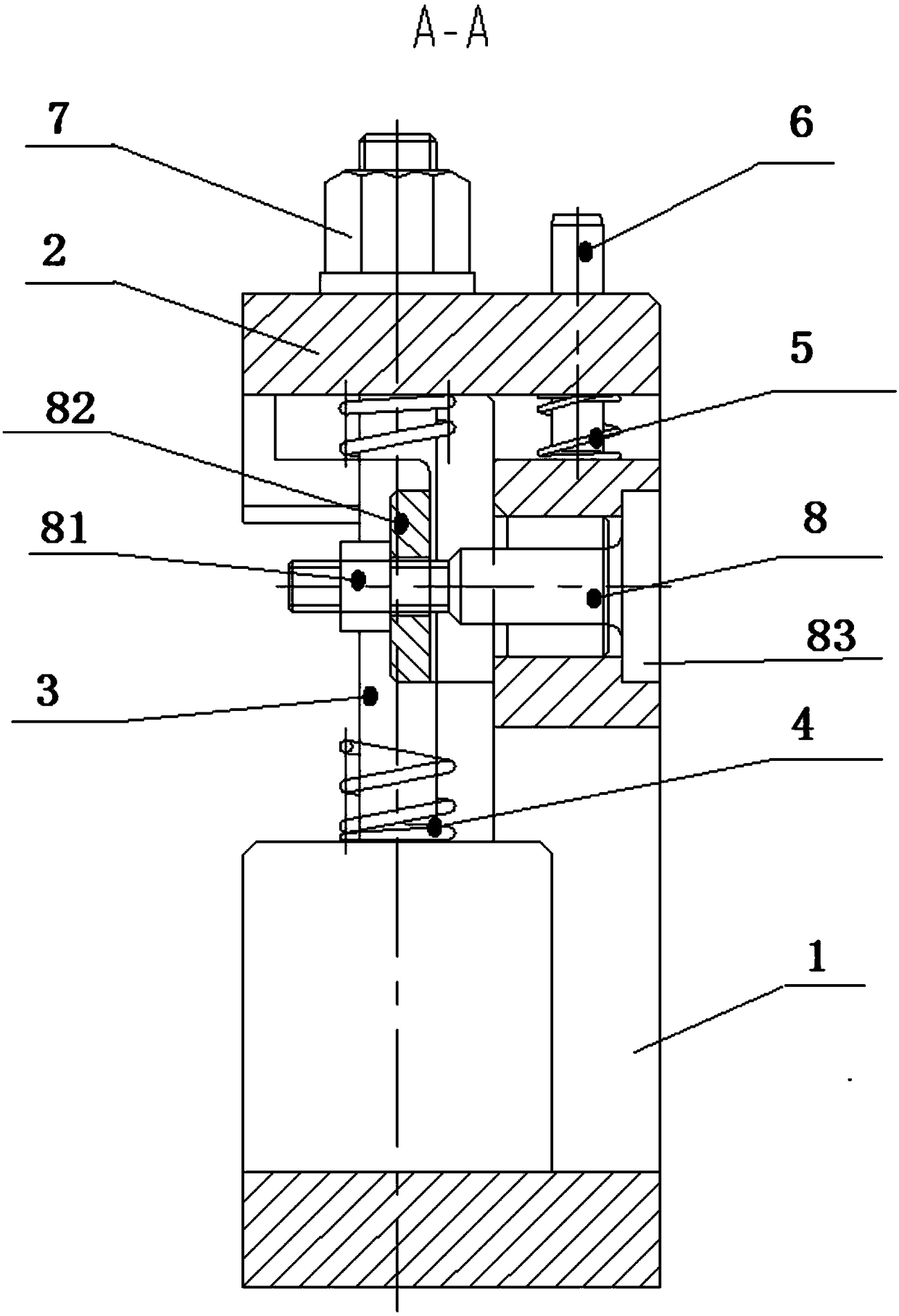

Needle bearing installing mechanism

ActiveCN103410875AImplement automatic installationImprove production and installation efficiencyBearing componentsBiomedical engineering

Owner:WUXI SHUANGYI PRECISION MACHINERY

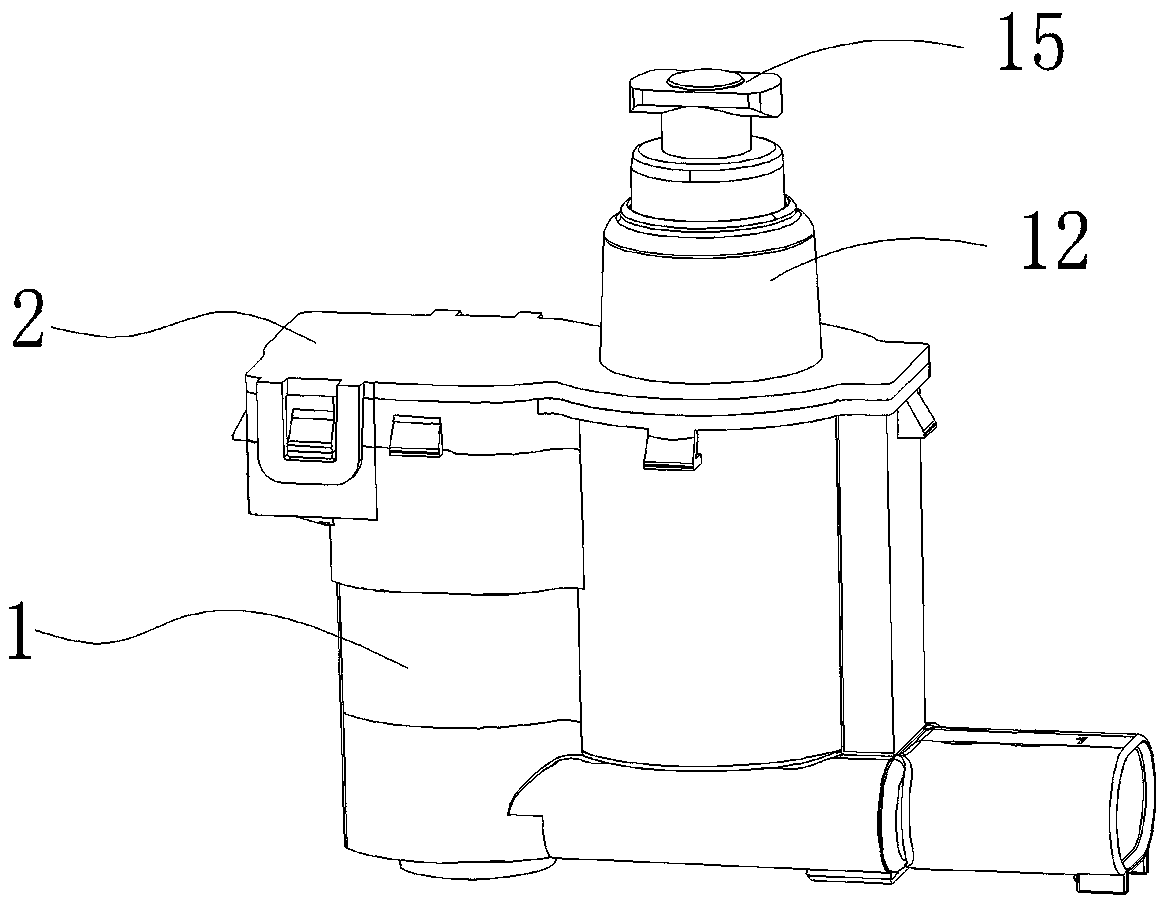

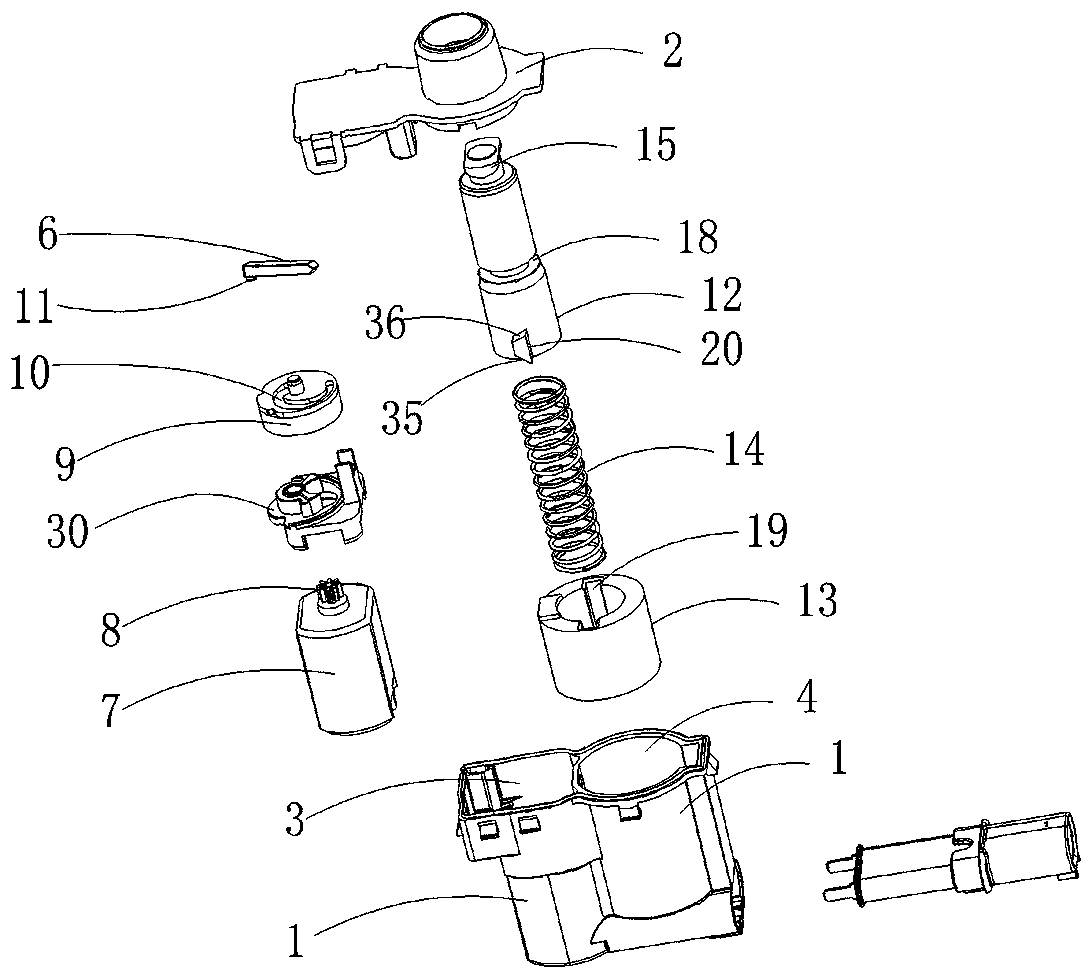

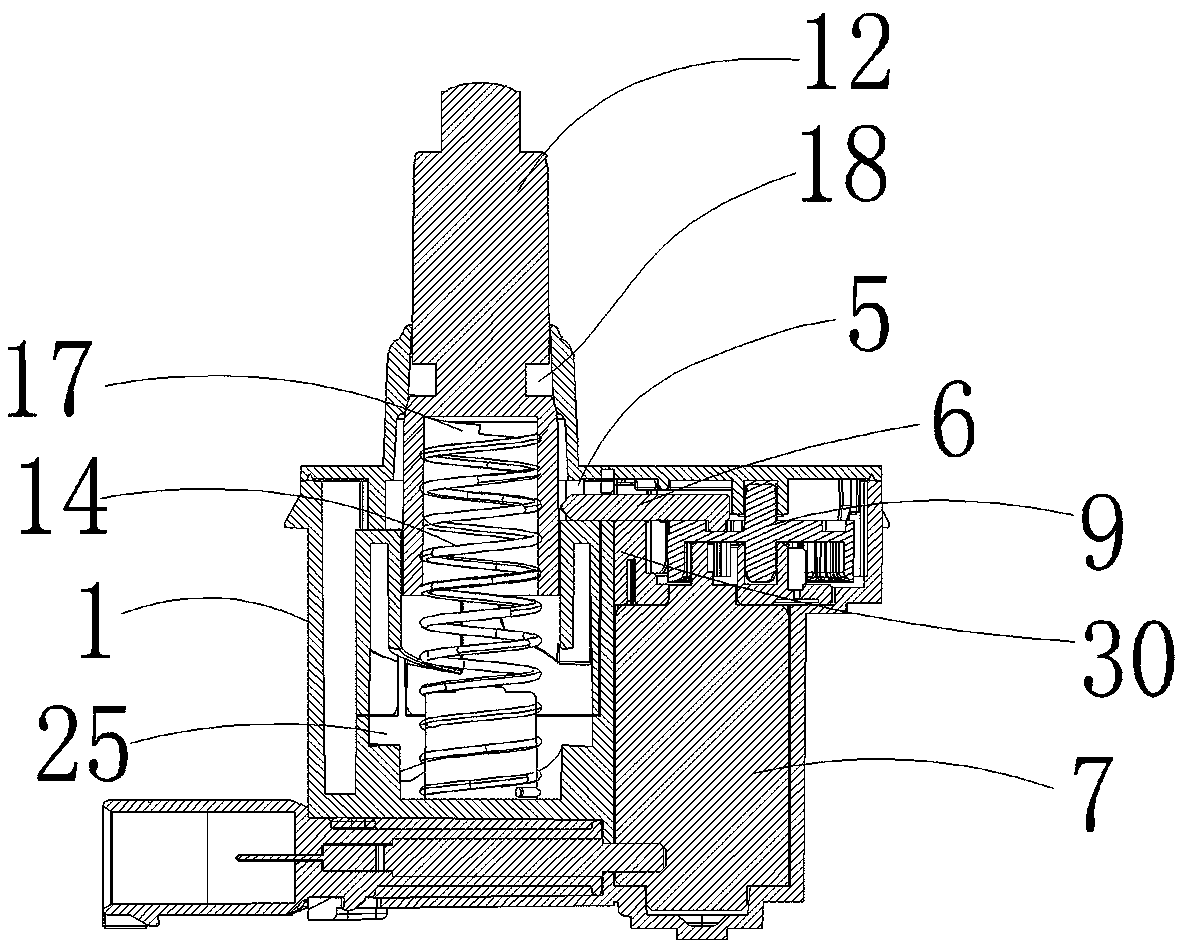

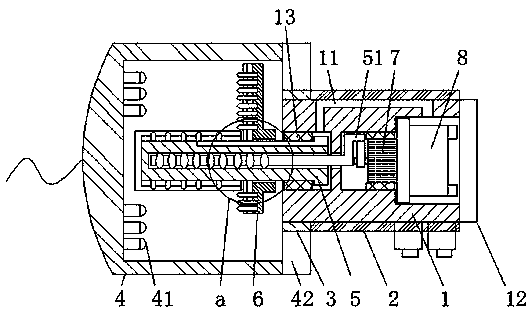

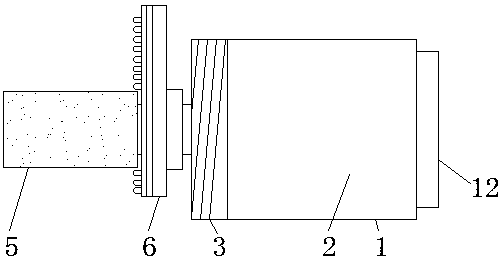

Automobile fuel tank cap actuator

ActiveCN109025558ARealize latchingRealize unlockingNoise-prevention/anti-rattling lockingPower transmission/actuator featuresLocking mechanismFuel tank

The invention provides an automobile fuel tank cap actuator which comprises a base and a base cover arranged on the base in a covering mode. The inner part of the base is partitioned into a motor cavity and a locking cavity. An inserting hole communicating with the motor cavity and the locking cavity mutually is formed between the motor cavity and the locking cavity. A power mechanism is arrangedin the motor cavity and is in transmission connection with a spring bolt. A locking mechanism is arranged in the locking cavity, and the spring bolt can penetrate through the inserting hole to be inserted into the locking mechanism. According to the automobile fuel tank cap actuator, an electric form and a mechanical form are combined, and the defects in the prior art are improved, thus misoperation is avoided, and the insurance effect is achieved; through cooperation of a motion lock shaft, a guiding lock sleeve and the locking cavity, the actions of circular sliding rotating and limiting onthe motion lock shaft are achieved, and locking or unlocking of an oiling little gate or a charging little gate is achieved; and the design is delicate, the structure is firm, durability is achieved,the production and mounting efficiency is improved, impact force and noise are effectively lowered, the overall service life of a product is prolonged, and the overall safety and comfortableness of the product are improved.

Owner:宁波海德欣汽车电器有限公司

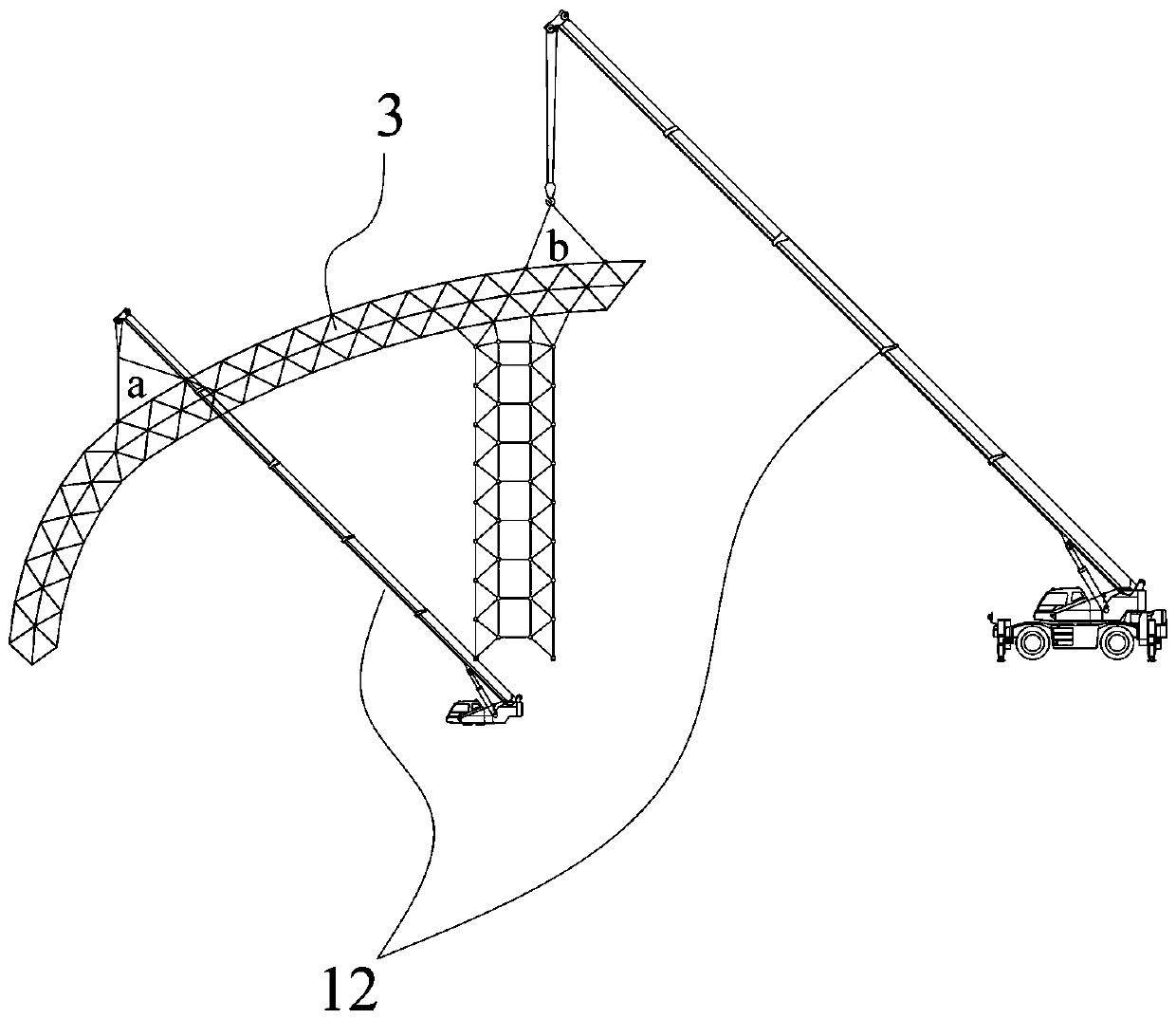

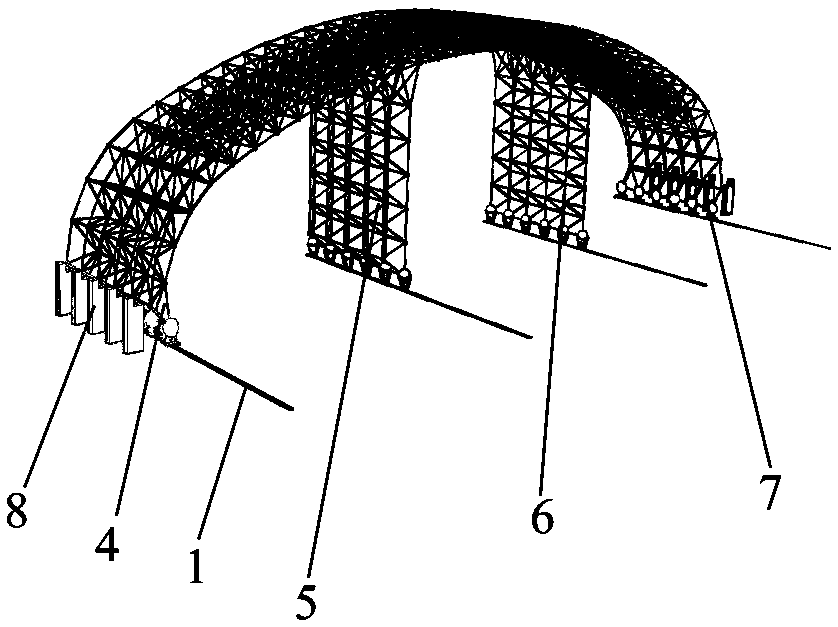

Installation method of long-span welded ball net rack

The invention relates to an installation method of a long-span welded ball net rack. The installation method comprises the following steps: dividing a net rack structure into a plurality of net rack units, and installing each span of unit by taking a slippage scaffold as a construction platform, wherein an arch frame of the slippage scaffold and two lateral supporting legs are all made of net rackunit materials; the lateral supporting legs are outwards opened by replacing rod pieces on the lateral supporting legs, so that an angle between the lateral supporting legs and the arch frame is increased to be the same as the size of each net rack unit, and then the lateral supporting legs are used as the net rack units applied to the end parts of the arch net rack. Two middle supporting legs comprise main body materials of a gable net rack and part of action rod pieces; after a net rack main body is mounted, the middle supporting legs rotate 90 degrees and then are assembled and installed on a gable, and the action rod pieces are cut off for utilization, so that the use amount of an action material is greatly reduced; in addition, the workload of removing the slippage scaffold is also reduced, and the labor intensity and the construction cost are substantially reduced.

Owner:CHINA MCC20 GRP CORP +1

Compact frame dedicated motor

ActiveCN104037977AReduce horizontal dimension spaceImprove drive transmission efficiencyMechanical energy handlingDrive wheelReduction drive

The invention discloses a compact frame dedicated motor comprising a motor, a speed reducer and a clutch. The motor, the speed reducer and the clutch are combined together in a transmission way so that a tubular compact frame dedicated motor integrated structure is formed. In the tubular compact frame dedicated motor, the motor is directly connected with the clutch via a planetary gear speed reducing mechanism of the speed reducer. Transmission is outputted to a transmission shaft by the clutch so that compact frame driving wheels arranged at the two ends of the transmission shaft are driven, and thus a compact frame body is driven to move. The driving structure is integrally simpler, production installation operation is simpler, convenient and rapid, and production efficiency is high without using transmission of a transmission chain for driving the compact frame by the motor so that an intermediate transmission link of the transmission chain is saved, and space occupied by installation of the whole driving device of the electric compact frame is reduced to a larger extent. Convenient and rapid performance of production installation, disassembling maintenance and repairing operation are enhanced, and fault identification judgment is more accurate, rapid and effective.

Owner:宁波八益智能存储系统有限公司

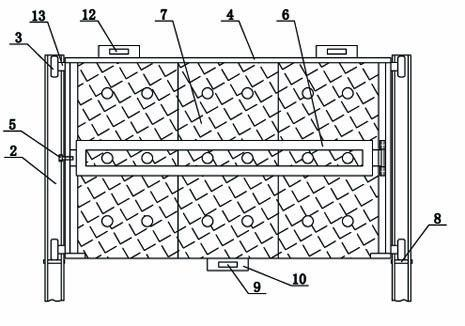

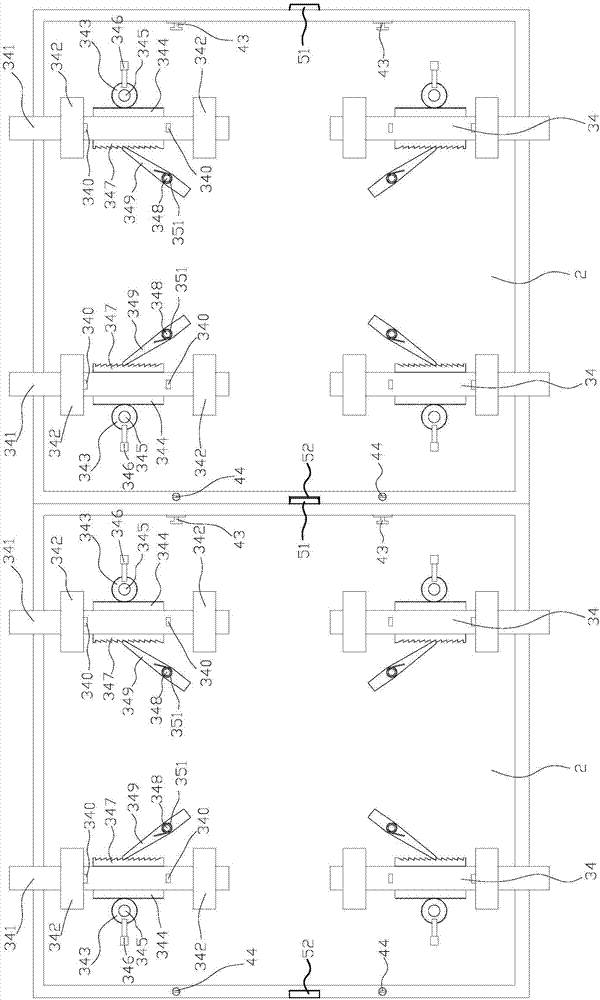

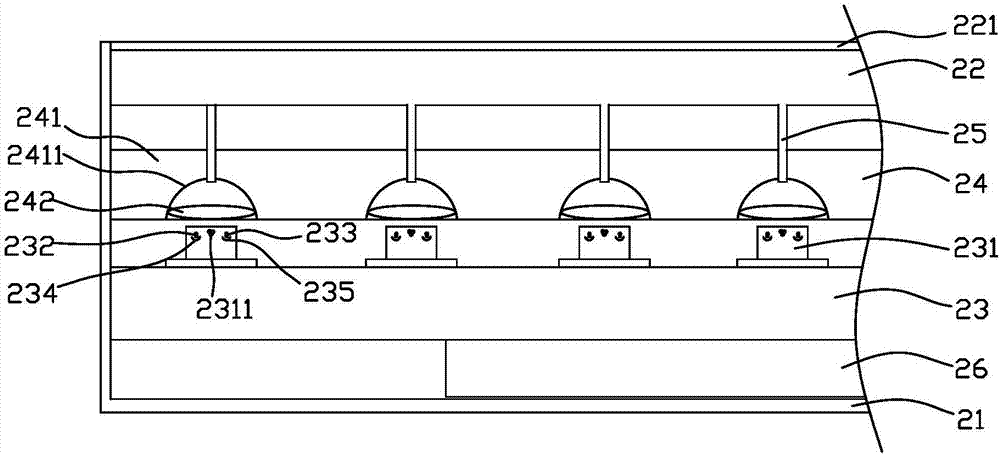

Large modular touch-control display screen

PendingCN107195254AReduce manufacturing costImprove production and installation efficiencyInput/output processes for data processingIdentification meansEmbedded systemComputer hardware

The invention discloses a large modular touch-control display screen. The large modular touch-control display screen includes an installation frame and a plurality of display screen modules arranged on the installation frame; the display screen modules are fixedly installed on the installation frame through a module fixing mechanism, the two adjacent display screen modules are fixedly connected through a module connecting mechanism, the two adjacent display screen modules are electrically connected through a module inserted-connection mechanism, the installation frame includes a vertical support column and installation cross rods, the two adjacent installation cross rods are provided with a display screen fixing groove used for fixing the display screen modules, and the module fixing mechanisms are fixedly installed on the installation frame through the display screen fixing grooves. The large modular touch-control display screen has the advantages that modular production can be achieved, assembly and maintenance are convenient, the production cost is low, the touch control sensitivity is high, touch control is accurate and the display effect is good, and the prior art does not have such advantages.

Owner:SHENZHEN LIANTRONICS +1

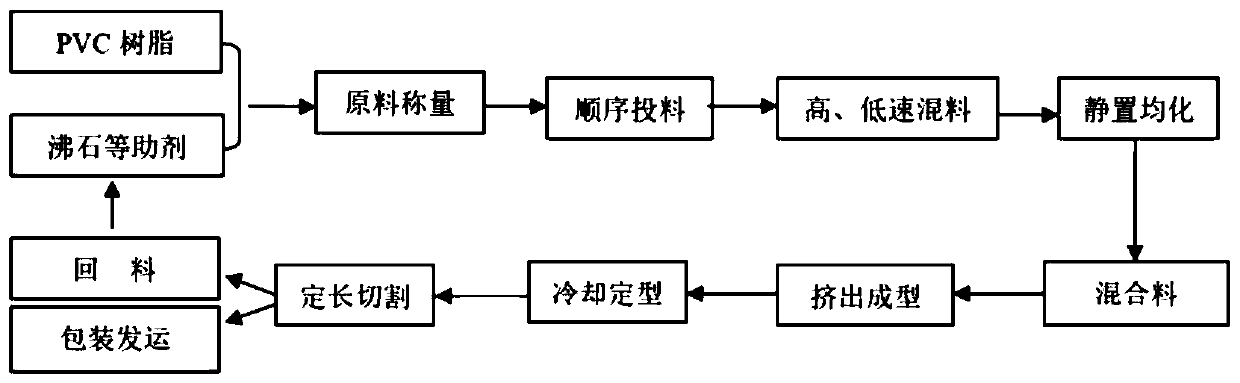

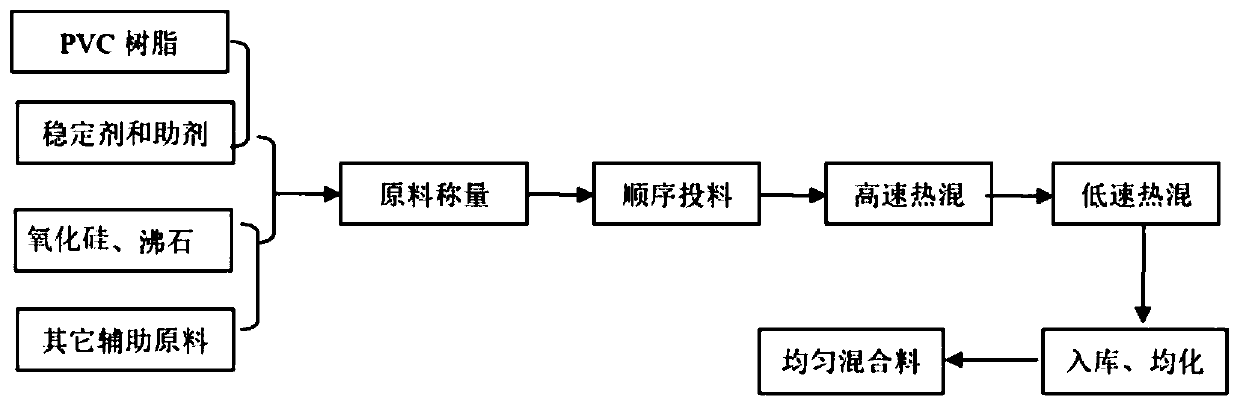

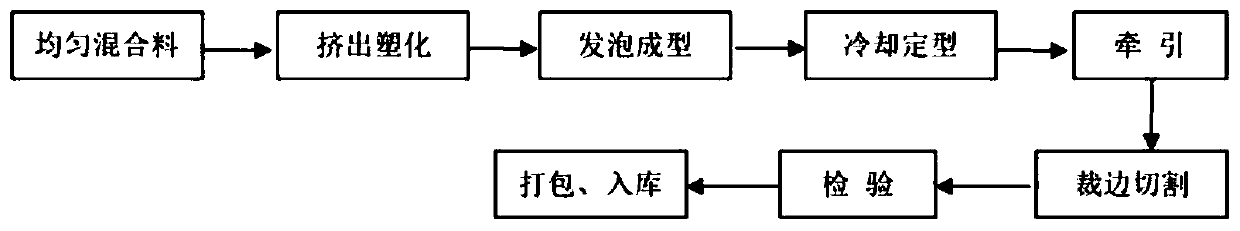

Formaldehyde-free odorless PVC foamed sheet and processing method thereof

The invention provides a formaldehyde-free odorless PVC foamed sheet and a processing method thereof. Compared with the prior art, on the basis of a calcium-zinc environment-friendly formula, siliconoxide and zeolite are applied to a PVC foamed sheet formula, and the formaldehyde-free odorless PVC foamed sheet is researched and developed. Moreover, a corresponding production method is designed according to the characteristics of the formula. The formaldehyde-free odorless PVC foamed sheet provided by the invention is free of formaldehyde, has a remarkable formaldehyde absorption function dueto molecular sieve structures of silicon oxide and zeolite, can be widely applied to the fields of indoor furniture manufacturing, wall decoration, advertising bathroom accessories and the like, and improves the ecological environment-friendly performance of furniture boards.

Owner:WUHU CONCH NEW MATERIAL

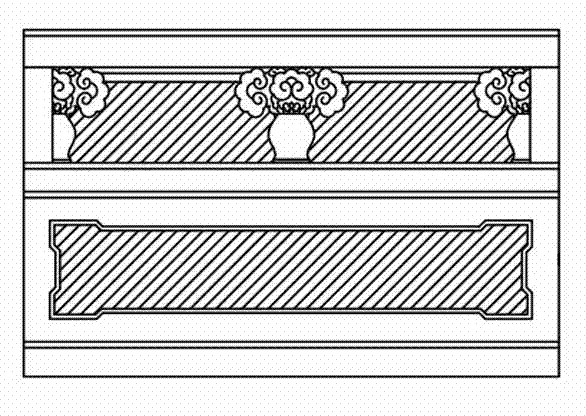

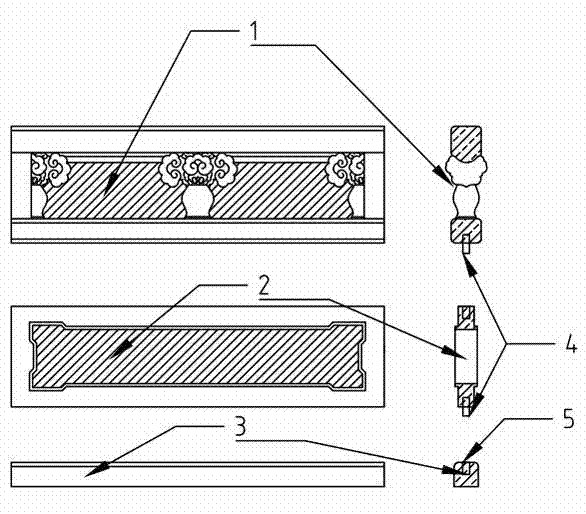

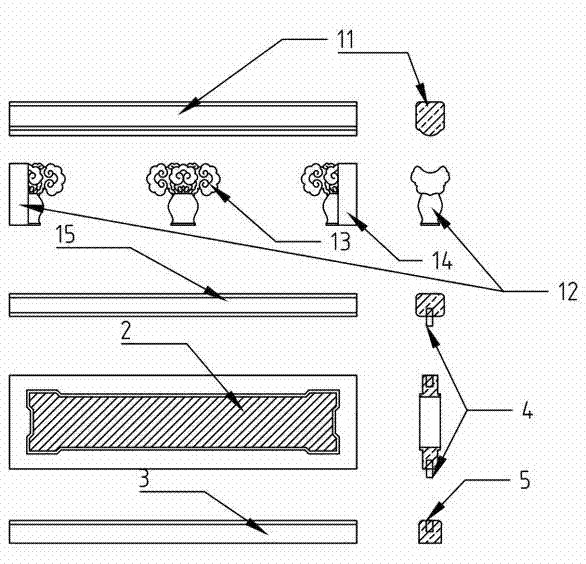

Stone balustrade and making and mounting process thereof

InactiveCN103046707AImprove production and installation efficiencyReduce material requirementsStairway-like structuresBuilding materialStructural engineering

The invention discloses a stone balustrade and a making and mounting process thereof. The stone balustrade is formed by splicing more than two partitioned stone components, tenon components matched in size and shape are arranged at spliced positions among the stone components, each tenon component comprises a rigid rabbet arranged in an oillet of the stone component on one side and a mortise arranged on the butted stone component on the other side, and the stone components are processed and shaped respectively and spliced into an integral stone balustrade through the tenon components. By the application and implementation of the technical scheme, compared with conventional making and mounting processes for stone balustrades, the stone balustrade and the making and mounting process thereof have the advantages that split processing first and assembling second is adopted, so that requirements on choosing stone materials are lowered, and stone saving is facilitated; mechanized processing can be adopted locally, so that large-scale working making is facilitated; and transport is convenient, so that making and mounting efficiency of the stone balustrades as ancient garden building materials is greatly improved.

Owner:SUZHOU GARDEN DEV

Water channel structure with adjustable gradient

InactiveCN105350496ASimple structureEasy to installArtificial water canalsWater storageWater channel

The invention discloses a water channel structure with an adjustable gradient. The water channel is formed by splicing a plurality of splicing water channel bodies. Each splicing water channel body comprises a bottom plate and side plates arranged on the two sides of the bottom plate, wherein the bottom plate is connected with the side plates through rotating shafts, the side plates and the bottom plate can rotate through the rotating shafts, and sealing gaskets are arranged between the side plates and the bottom plate. The water channel has the characteristics of being simple in structure, convenient to mount, good in water storage performance and the like. Meanwhile, according to the water channel structure with the adjustable gradient, the gradient of the water channel can be adjusted according to site conditions; through the water channel, a method for casting a traditional water channel in place is replaced, and the production and mounting efficiency is greatly improved.

Owner:李文霞

Drilling device for workpieces with special-shaped structures

PendingCN108942316AGuaranteed dimensional accuracySimple, novel and compact structurePositioning apparatusMetal-working holdersTemplate designBiomedical engineering

Owner:TIANJIN RAILWAY SIGNAL

Novel photovoltaic bracket

PendingCN109379024AImprove production and installation efficiencyEasy tension adjustmentPhotovoltaic supportsPhotovoltaic energy generationClosed loopStructural engineering

The invention discloses a novel photovoltaic bracket comprising high and low vertical columns, flexible primary and secondary support cables, a tracking bracket, a vertical swing arm, a transmission cable, east-west main and auxiliary transmission wheels and a driving device, wherein the flexible primary and secondary support cables are connected to and pull the high and low vertical column support portions at the easy and west ends respectively; the flexible primary support cable is higher than the flexible secondary support cable and is parallel to the flexible secondary support cable to form a sun-facing inclined slope; the transmission cable is placed under and in parallel to the flexible primary support cable, and is in closed-loop connection with the east-west main and auxiliary transmission wheels on the support portions; the north and south ends of the tracking bracket are rotatably fixed to the flexible primary and secondary support cables; the upper and lower ends of the vertical swing arm are fixedly connected with the north end of the tracking bracket and the transmission cable under the tracking bracket respectively; the driving device is connected with the main transmission wheel, so that the tracking bracket where an photovoltaic component is embedded can be rotated in the east-west direction. The novel photovoltaic bracket solves the technical problem that a bracket in the prior art cannot be rotated or is difficult in rotation adjustment, low in efficiency and high in manufacturing and installing cost.

Owner:南京市光翔新能源科技有限公司

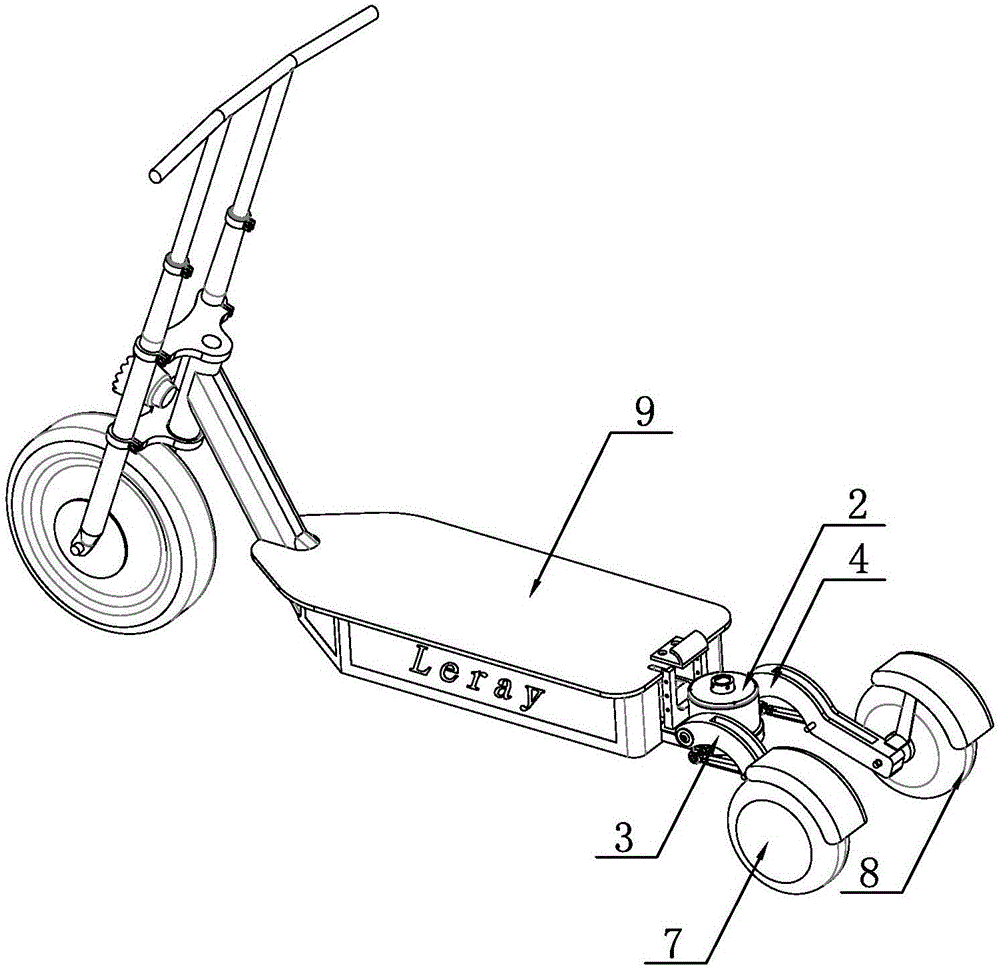

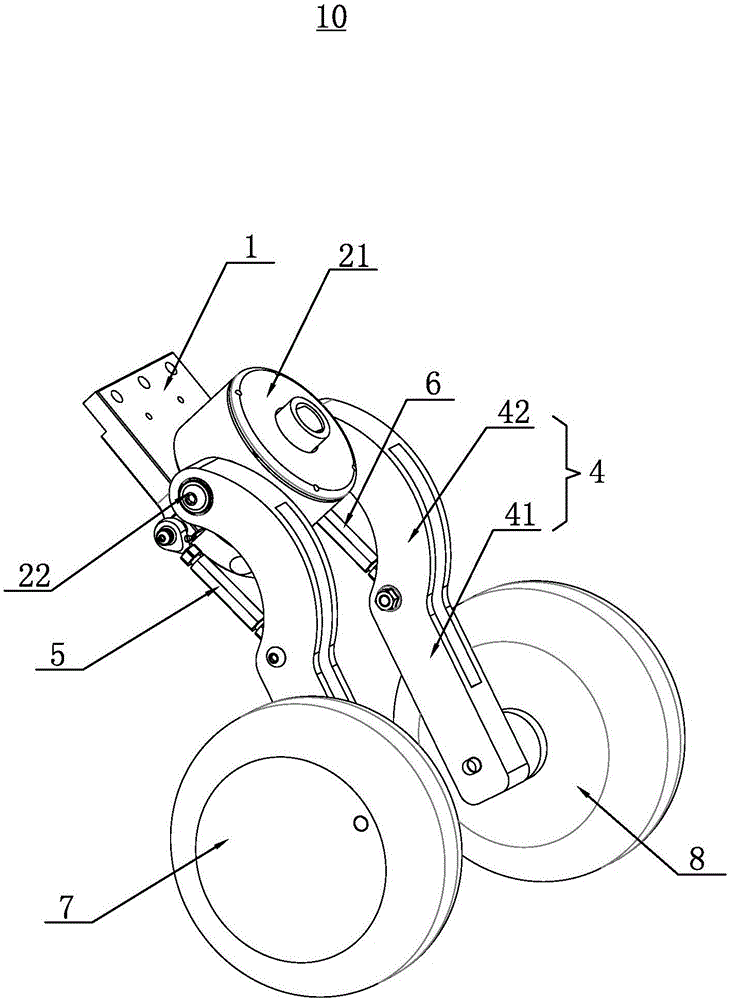

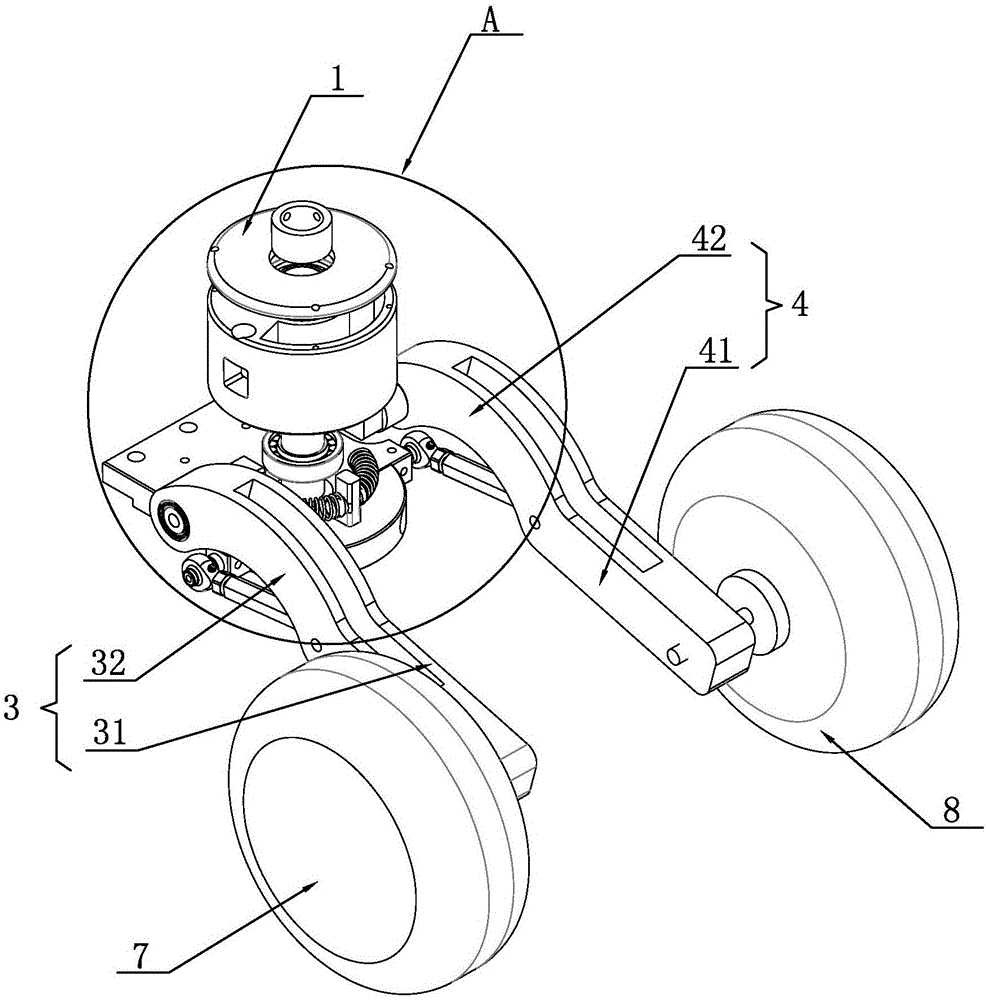

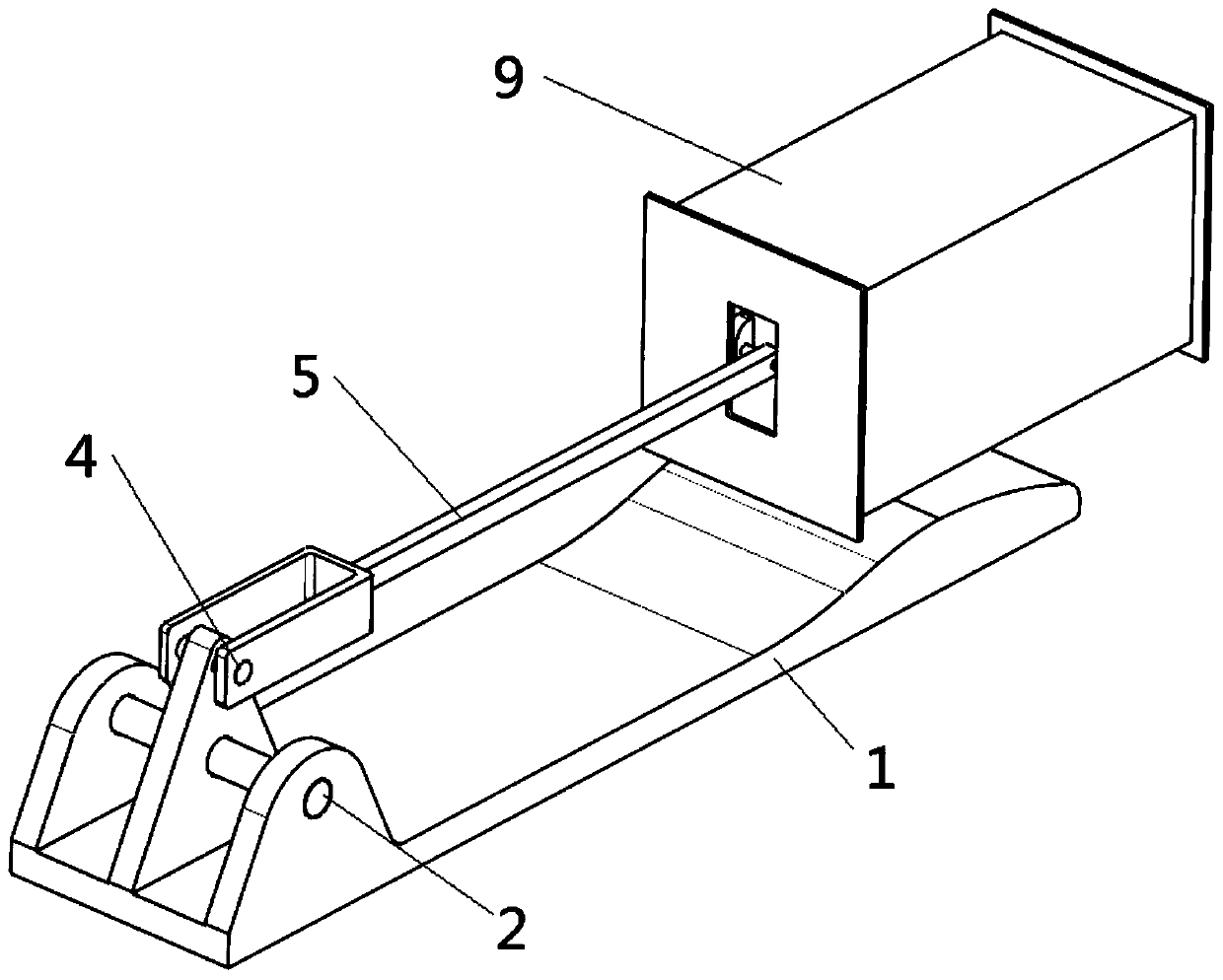

Rear-wheel assembly structure of three wheels scooter and three wheels scooter

ActiveCN106741520AReduced chance of rolloverImprove production and installation efficiencyCyclesAxle suspensionsEngineeringMechanical engineering

The invention discloses a rear-wheel assembly structure of a three wheels scooter. The rear-wheel assembly structure comprises a main scooter frame, a base plate connecting block, an abrasive disk component, a first rear wheel, a second rear wheel, a first scooter wheel support, a second scooter wheel support, a first limiting piece used for limiting the movement of the first scooter wheel support, and a second limiting piece used for limiting the movement of the second scooter wheel support, wherein the base plate connecting block is connected to the main scooter frame; the abrasive disk component is connected to the base plate connecting block, and is provided with a first end and a second end which are oppositely arranged; one end of the first scooter wheel support is fixedly connected to the first rear wheel, and the other end of the first scooter wheel support is movably connected to the first end of the abrasive disk component; one end of the second scooter wheel support is fixedly connected to the second rear wheel, and the other end of the second scooter wheel support is movably connected to the second end of the abrasive disk component; one end of the first limiting piece is connected with the base plate connecting block, and the other end of the first limiting piece is connected to the second scooter wheel support. The invention further provided the three wheels scooter which comprises the rear-wheel assembly structure.

Owner:X L T INT ELECTRONICS

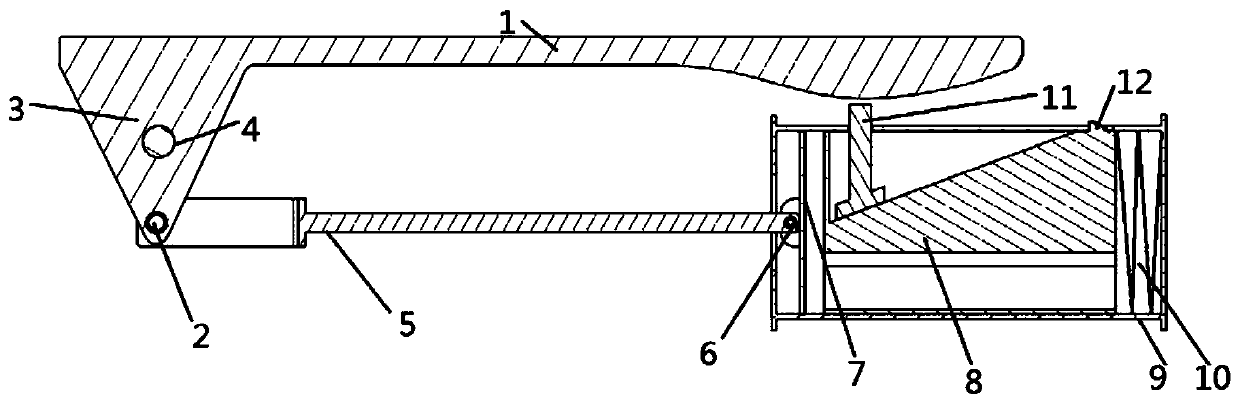

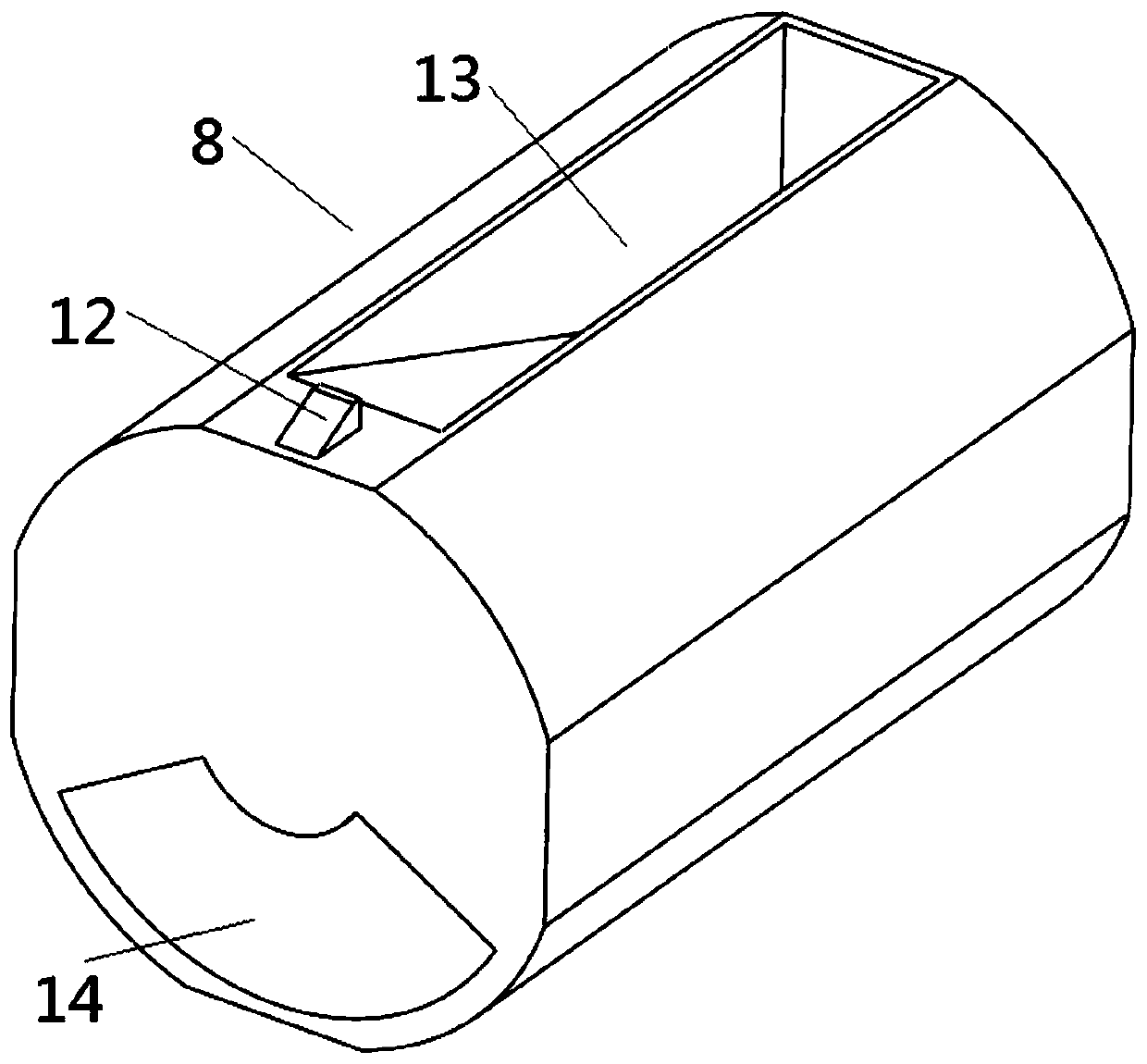

Self-ejecting self-resetting hidden type car door handle mechanism

The invention relates to a self-ejecting self-resetting hidden type car door handle mechanism. The mechanism comprises a car door handle with one end provided with a connecting part, the middle of theconnecting part is rotatably connected with a car door metal plate, the end of the connecting part is movably connected with the end of a connecting rod, the other end of the connecting rod is movably connected with a sliding block, the sliding block is in sliding connection into a sleeve column, a compression spring and cavity rubber between the compression spring and the sliding block are arranged in the sleeve column, a protruding buckle is arranged on the upper surface of the end, close to the compression spring, of the cavity rubber, the sleeve column is provided with a limiting hole matched with the protruding buckle, a wedge groove is formed in the upper surface of the cavity rubber, an ejecting column is arranged on the bottom face of the wedge groove, the upper end of the ejecting column penetrates through the sleeve column to be in contact connection with the car door handle, and a cavity is formed in the lower end of the cavity rubber. Compared with the prior art, the mechanism has the advantages of being compact in structure, convenient to mount, high in safety property and the like and is particularly suitable for children and the crow with the small hands.

Owner:SHANGHAI COTECH AUTOMOTIVE ENG CORP LTD

Ear massager for tinnitus rehabilitation

InactiveCN109646275AActive connectionImprove the bactericidal effectVibration massageTherapeutic coolingMassageTinnitus

The invention discloses an ear massager for tinnitus rehabilitation. The massager comprises a grip, an external thread and a small motor. An outer protective sleeve wraps the outer side of the grip, an end cover is installed at the right side of the grip through a bolt, the external thread is arranged at the left side of the outer side of the grip, a sterilizing cover is arranged at the left partof the grip, an auditory meatus massage bar is arranged at the left side of the middle of the grip, an auricle massage plate is arranged in the middle of the auditory meatus massage bar, the small motor is installed inside the grip, a storage battery is arranged at the right side of the small motor, an eccentric wheel is installed at the output end of the small motor, a buffer strip is arranged atthe outer side of the small motor, a first wire slot is formed in the upper surface of the grip, and a buffer layer is embedded into the inner side of the left side of the grip. The ear massager fortinnitus rehabilitation is provided with an auricle massage plate, in the using process, by cooperatively using the auditory meatus massage bar, vibration is effectively performed, the auricle contouris massaged, and the practicability of the massager is ensured.

Owner:程泽星

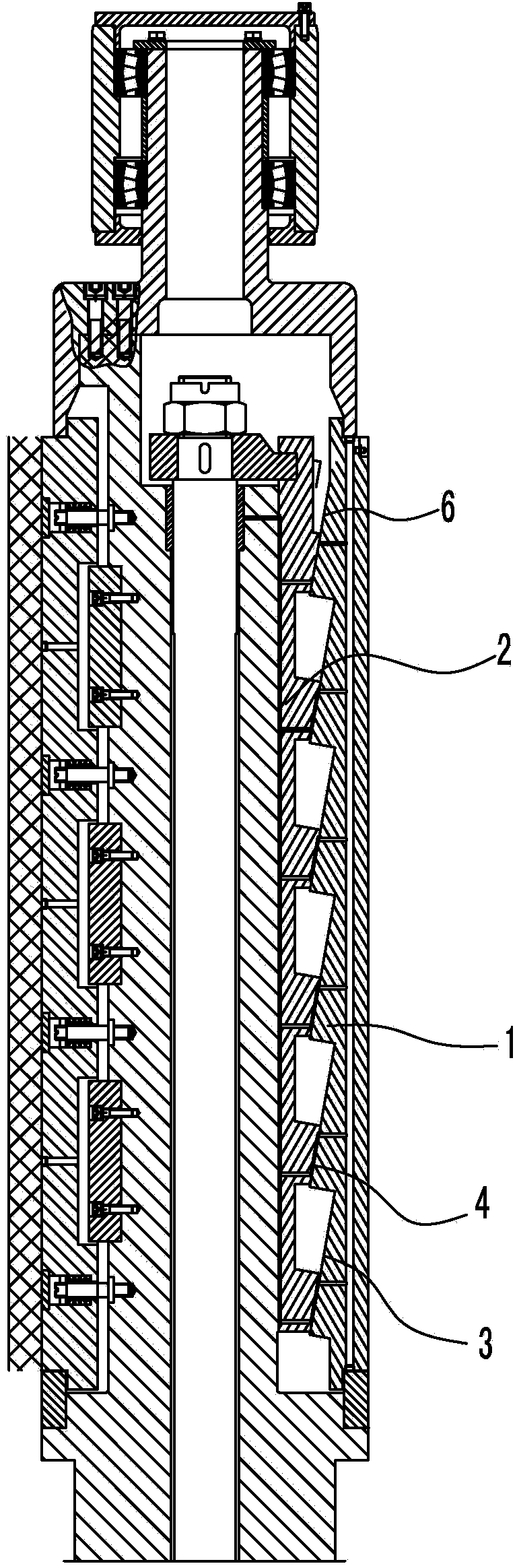

Live fast plug-in device for cable elbow joint and method

PendingCN110289527AQuick plugRealize live workTwo-part coupling devicesLive contact access preventionSwitch boxPower demand

The invention discloses a live fast plug-in device for a cable elbow joint and method. The live fast plug-in device for a cable elbow joint is applied between a switch box and a to-be-connected cable to conduct the power line on the switch box and the to-be-connected cable. The live fast plug-in device comprises a sleeve and a plug, wherein the sleeve is arranged on the switch box and comprises a conductive rod and a first insulating jacket, the conductive rod is electrically connected with the power line of the switch box, the first insulating jacket coats the outer surface of the conductive rod, and the top end of the conductive rod is provided with a plug-pull hole; and the plug comprises a plug-pull rod and a second insulating jacket, the second insulating jacket coats the outer surface of the plug-pull rod, the tail end of the plug-pull rod is crimped with the to-be-connected cable, the head end of the plug-pull rod is provided with a plug-pull part fit with the plug-pull hole, an accommodating hole exists between a plug-pull part and the second insulating jacket, and when the plug-pull part is plugged in the plug-pull hole, the accommodating hole sleeves the outer surface of the first insulating jacket in a matched mode. quick plug-in between the to-be-connected cable and the switch box can be realized, live operation can also be realized, and the phenomenon that power demands are affected by power failure does not happen.

Owner:GUIZHOU POWER GRID CO LTD

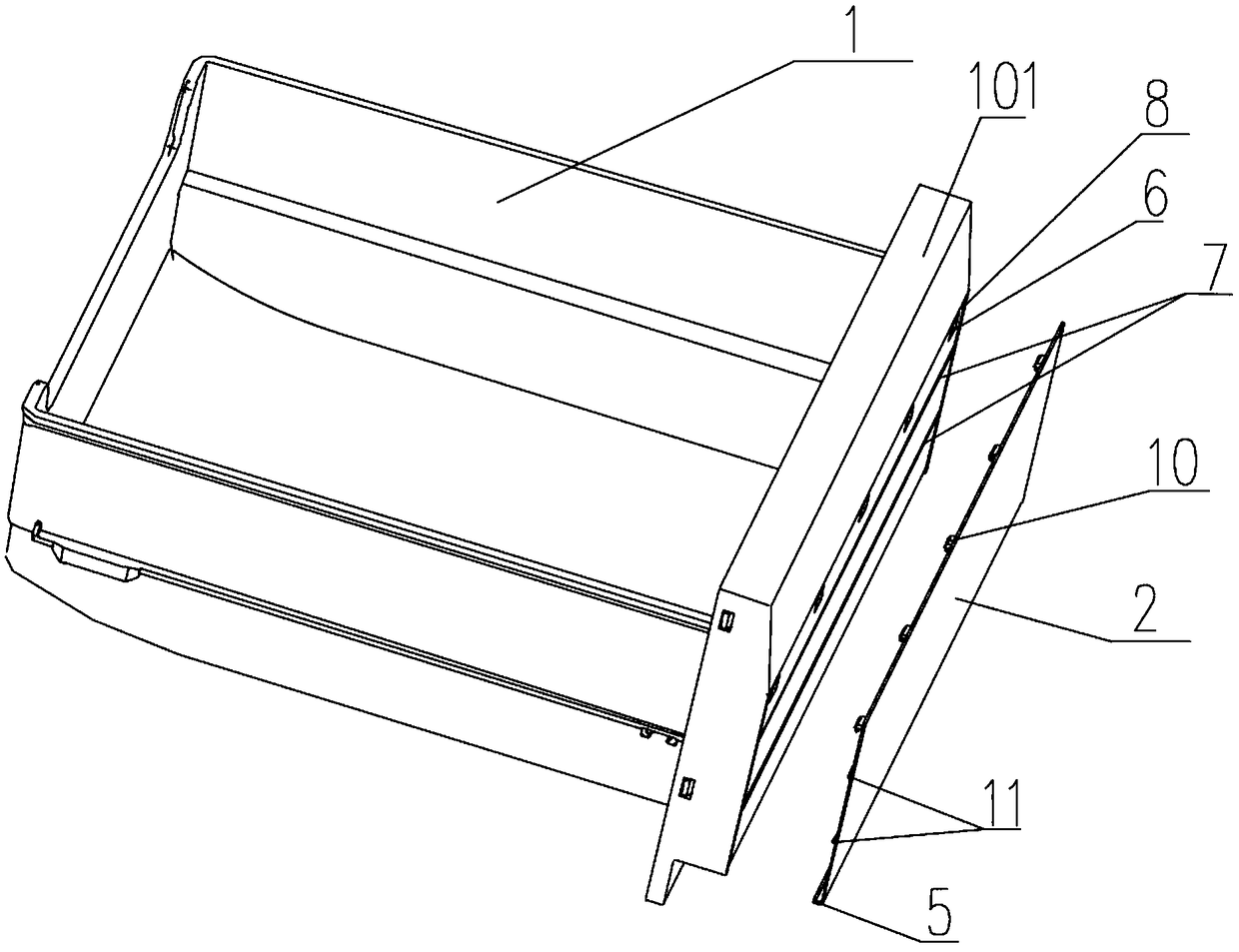

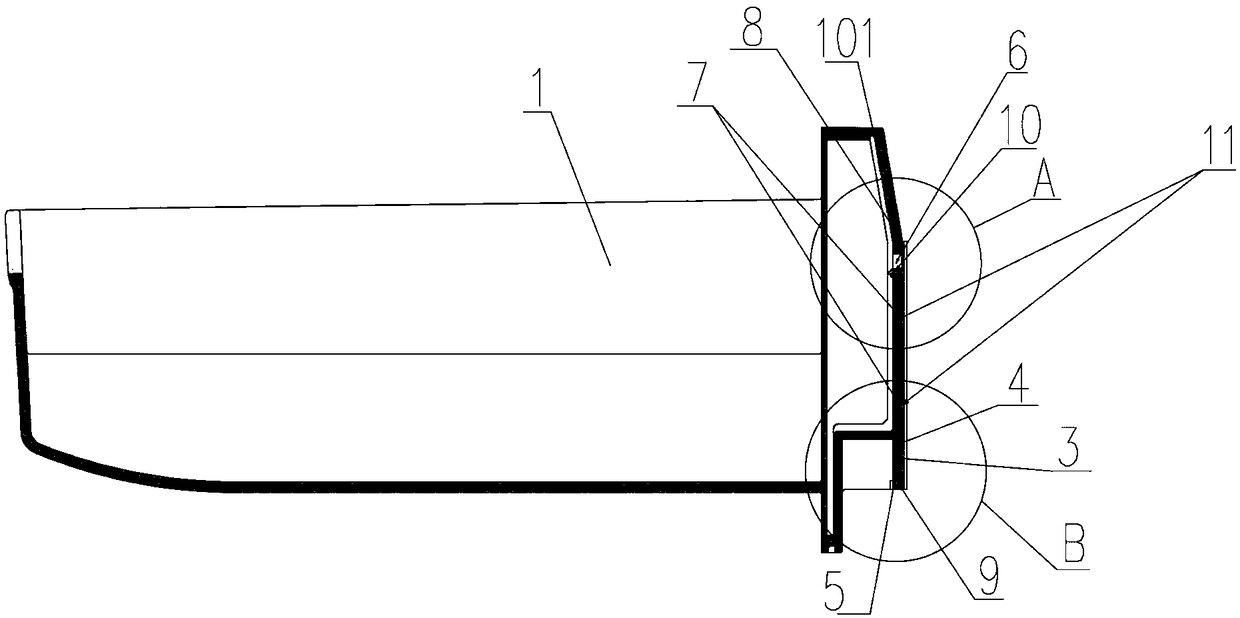

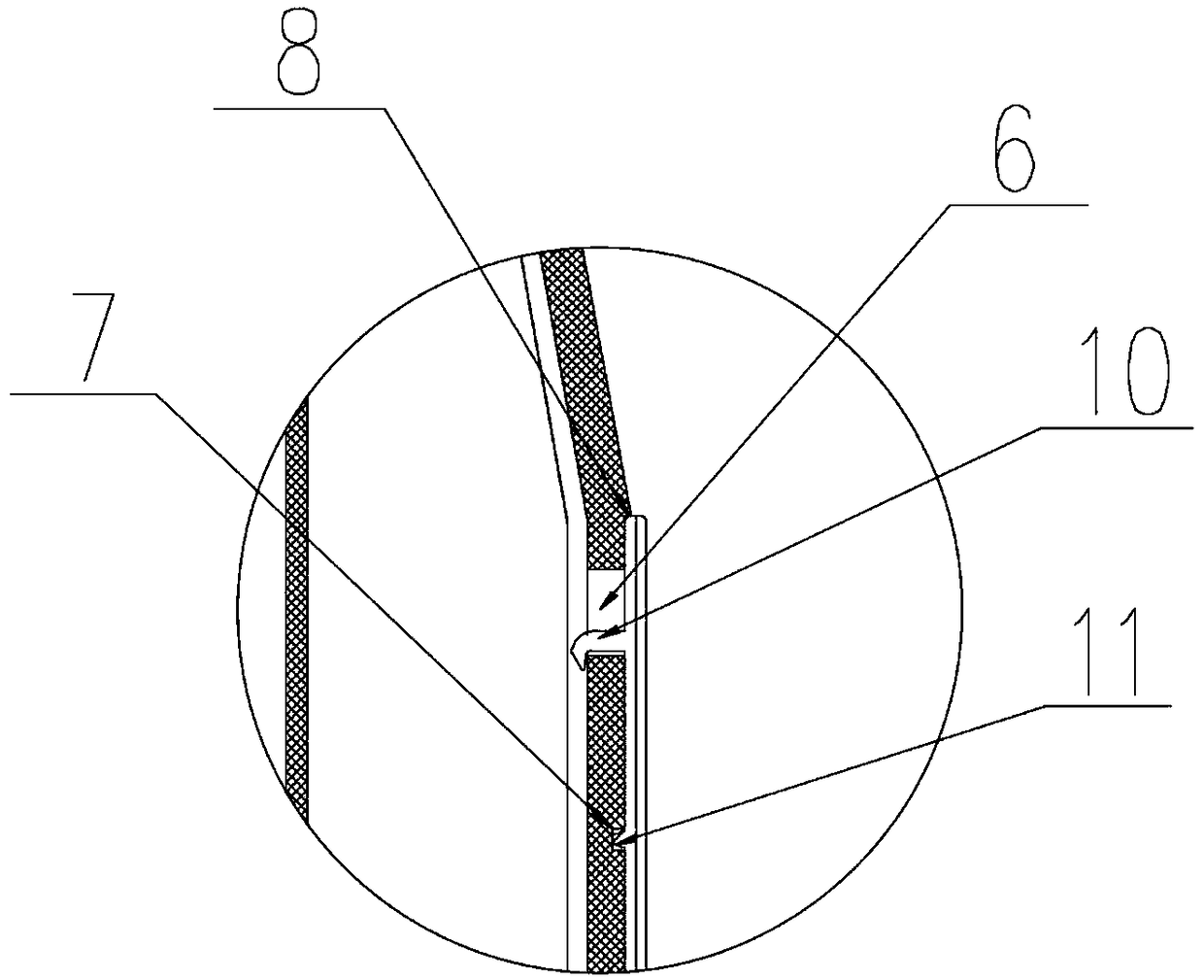

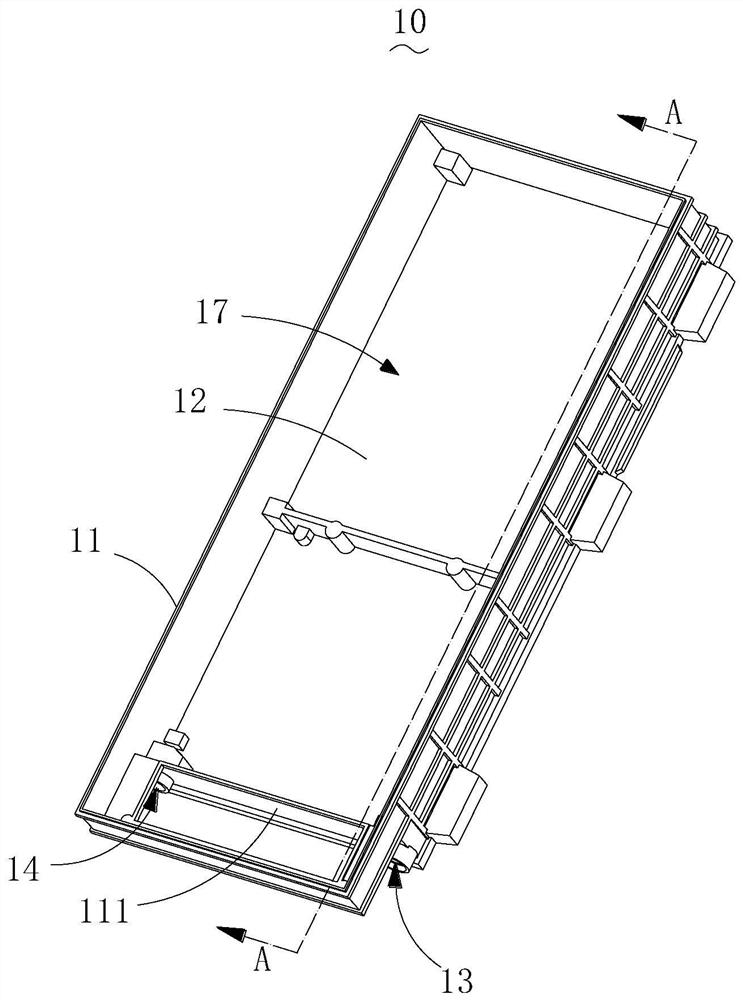

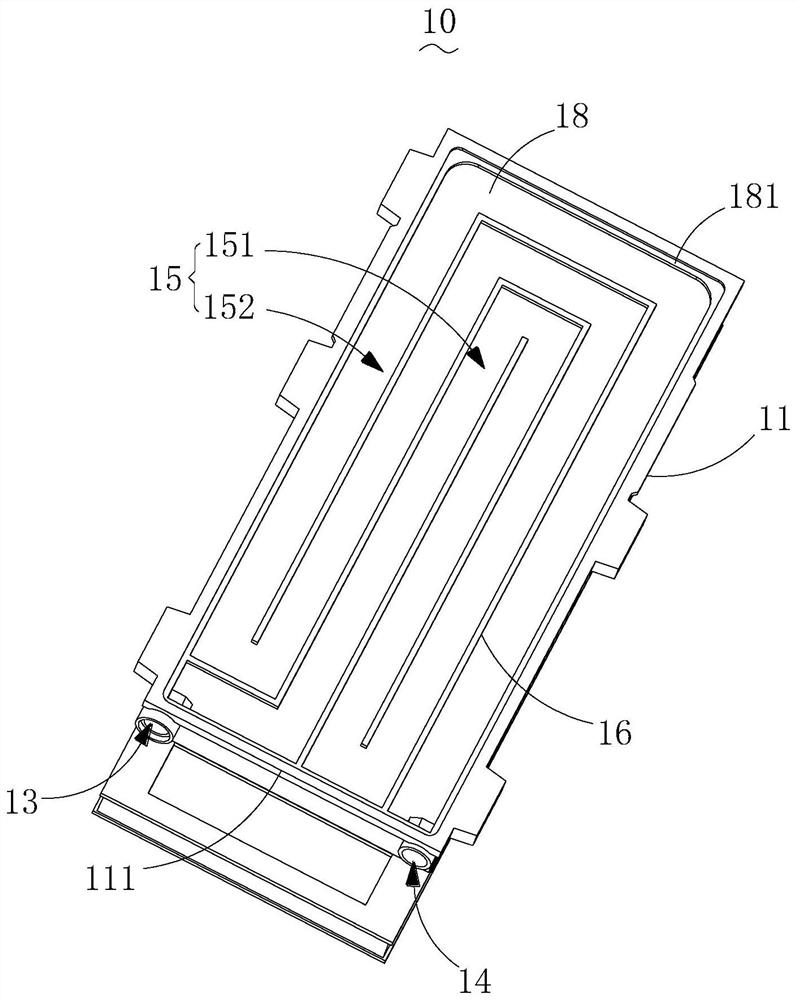

Multifunctional container of replaceable function indicating decorative board for refrigerator

PendingCN109442859AReduce manufacturing costImprove production and installation efficiencyLighting and heating apparatusSupportEngineeringSurface plate

The invention discloses a multifunctional container of a replaceable function indicating decorative board for a refrigerator, and relates to the field of refrigerator containers. The container comprises a container body matched with the refrigerator and provided with a front panel, a step-shaped mounting groove is formed in the outer surface of the front panel, the function indicating decorative board is clamped in the mounting groove, multiple clamping openings and transverse limiting grooves are formed in the inner surface of the mounting groove transversely at equal intervals, a limiting convex strip is transversely placed on the bottom of the front panel, and the function indicating decorative board comprises a function indicating clamping board and a function indicating decoration layer. The container is reliable and simple in assembling, screw hitting is not needed, and function decoration novelty is high. Due to the clamping structure of the function indicating decorative board,the problems that the refrigerator container is high in production cost, low in production line production efficiency and mounting efficiency and low in user experience degree are solved.

Owner:CHANGHONG MEILING CO LTD

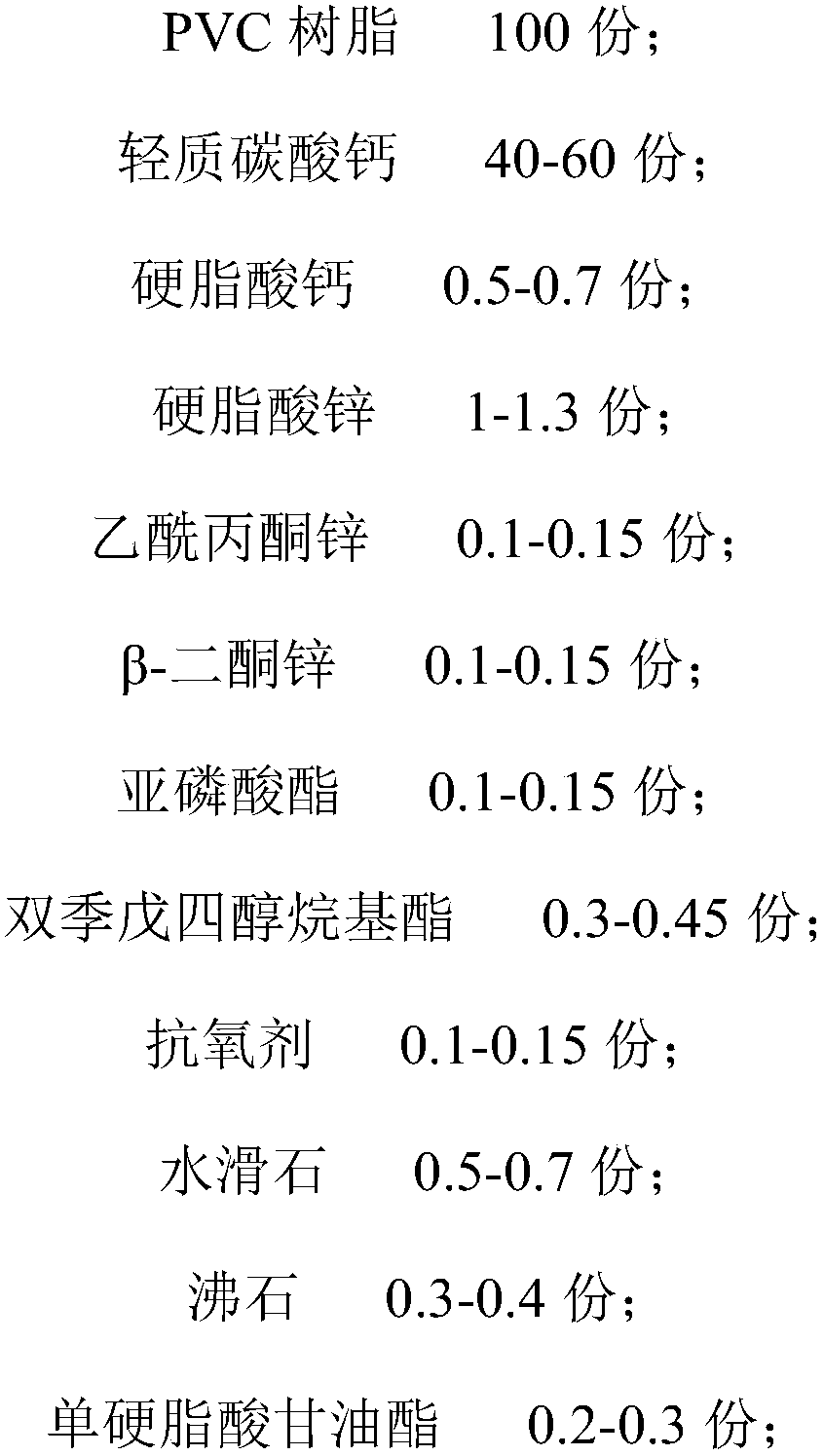

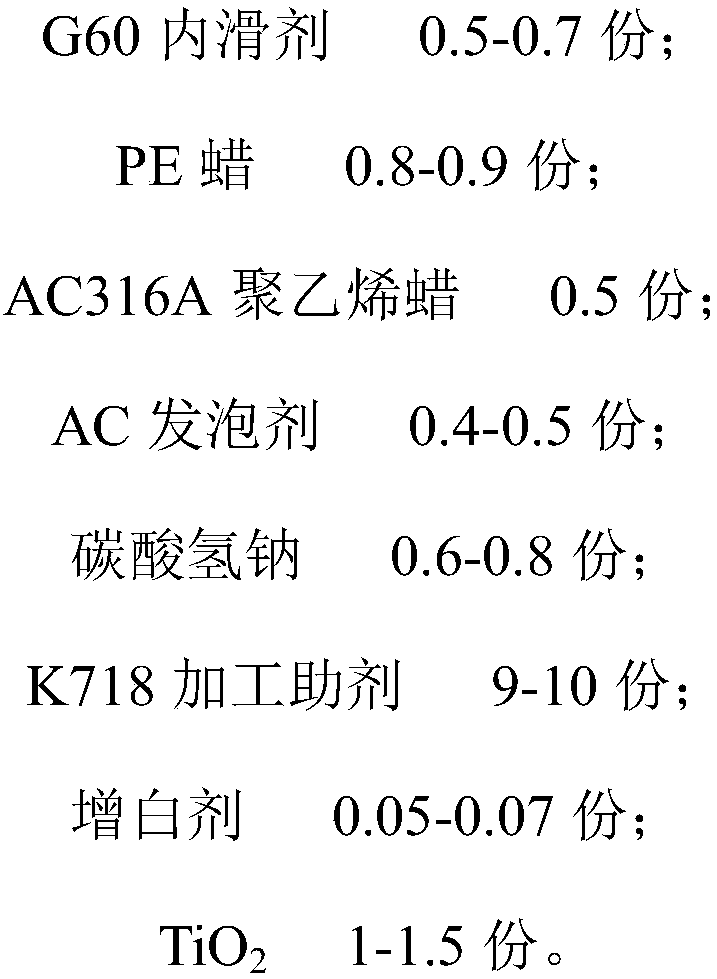

PVC furniture board and preparation method thereof

InactiveCN108586975AImprove plasticizing effectSolve the initial colorabilitySodium bicarbonateWhitening Agents

The invention discloses a PVC furniture board and a preparation method thereof. The PVC furniture board comprises the following raw materials by weight: PVC resin, light calcium carbonate, calcium stearate, zinc stearate, zinc acetylacetonate, zinc beta-diketone, phosphite ester, dipentaerythritol alkyl ester, an antioxidant, hydrotalcite, zeolite, glyceryl monostearate, an internal lubricant G60,PE wax, polyethylene wax AC316A, a foaming agent AC, sodium bicarbonate, a processing auxiliary agent K718, a whitening agent and TiO2. The PVC furniture board obtained by using the method provided by the invention is environmentally-friendly and safe, has good thermal stability, is uniform to foam, and has Shore hardness of no less than 70 D, tensile strength of no less than 12 Mpa, elongation at break of no less than 10% and a bending elastic modulus of no less than 1780 MPa.

Owner:WUHU CONCH NEW MATERIAL

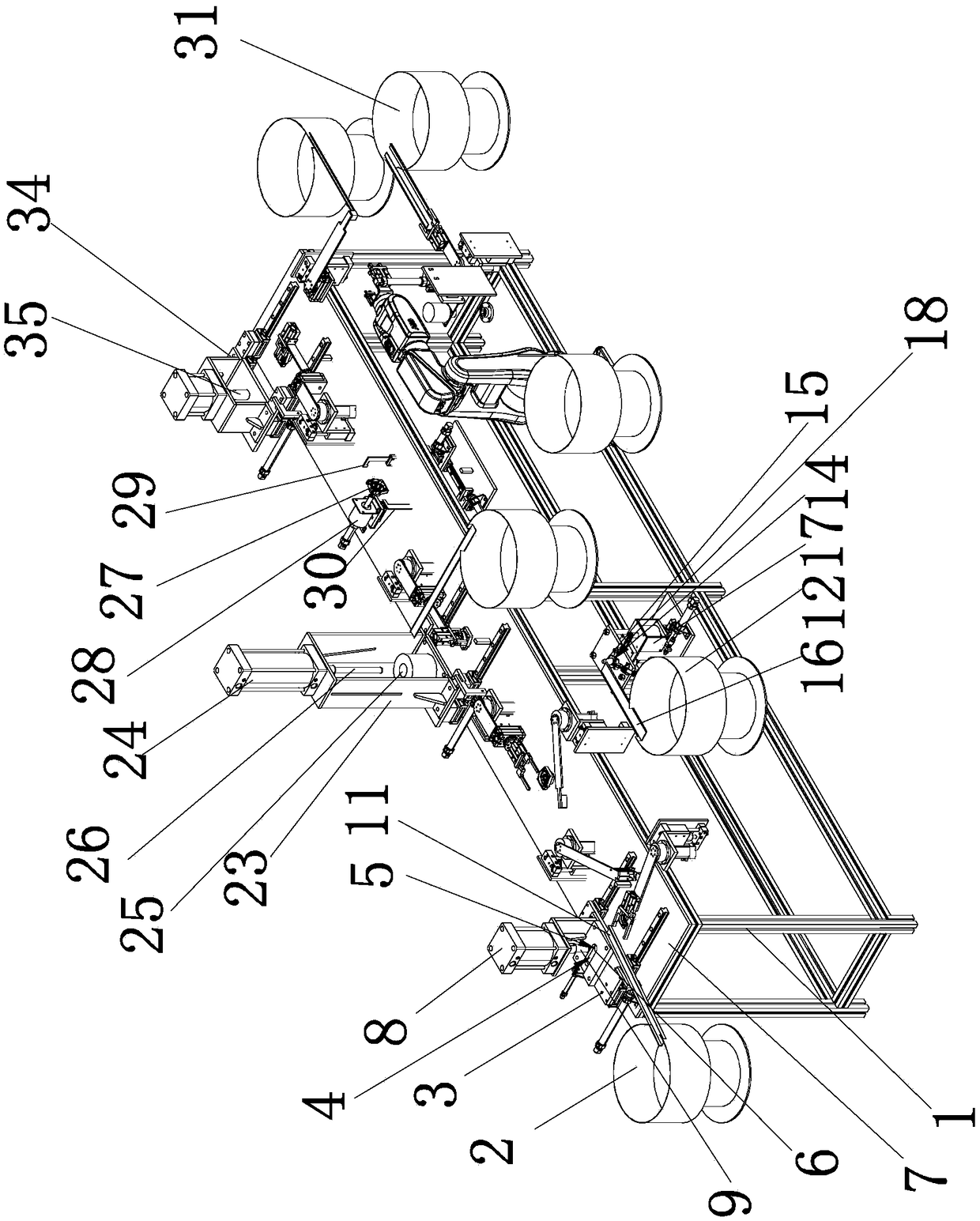

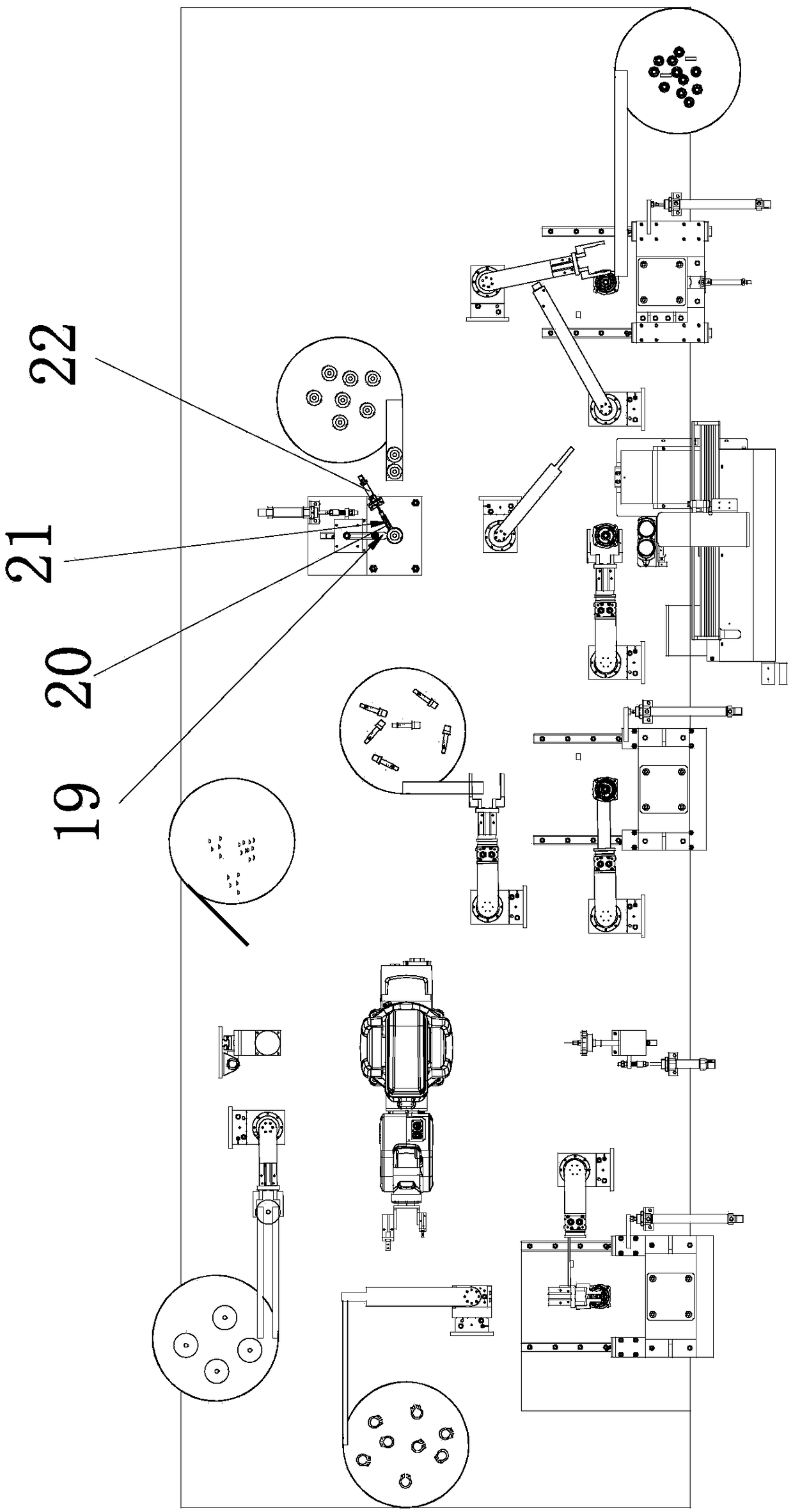

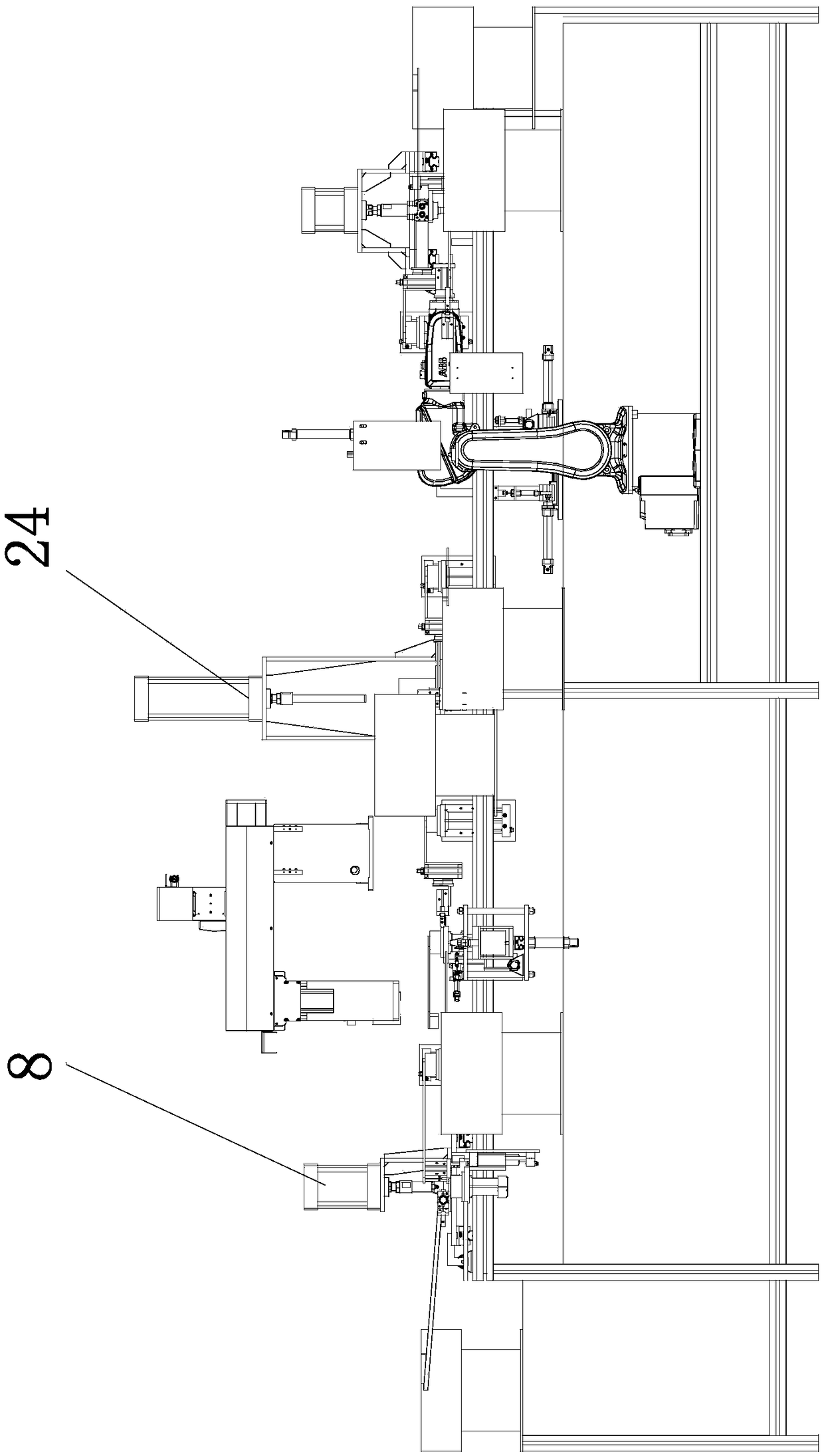

Automatic assembly production line for front cover of angle grinder

PendingCN109202445AAutomate installationImprove production and installation efficiencyAssembly machinesProduction lineAngle grinder

The invention provides an automatic assembly production line for a front cover of an angle grinder, and belongs to the technical field of angle grinder installation devices. The automatic assembly production line solves the problems of low installation efficiency of the front cover of an existing angle grinder. The automatic assembly production line comprises a frame, and a bearing mounting device, a baffle mounting device, a short shaft mounting device, a semi-circular key mounting device, a bevel gear mounting device and a retaining ring mounting device, which are arranged on the frame in sequence, wherein a conveying device is arranged between each two of the bearing mounting device, the baffle mounting device, the short shaft mounting device, the semi-circular key mounting device, thebevel gear mounting device and the retaining ring mounting device. The automatic assembly production line is provided with a bearing mounting device, a baffle mounting device, a short shaft mounting device, a semi-circular key mounting device, a bevel gear mounting device and a retaining ring mounting device, thereby realizing automatic assembly of bearings, baffles, short shafts, semi-circular keys, bevel gears and retaining rings. The production and installation efficiency of an angle grinder is improved, labor and enterprise production costs are reduced, and cost-effectiveness is achieved.

Owner:ZHEJIANG FOERTAI INTELLIGENT EQUIP CO LTD

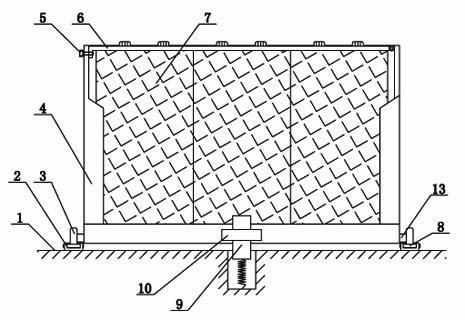

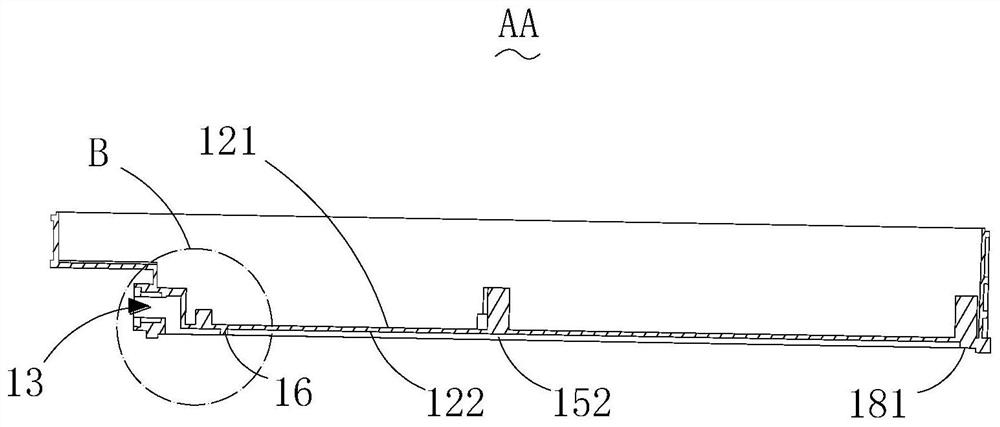

Liquid cooling plate integrated box body and battery box

PendingCN113611951AReduce weightSmall sizeSecondary cellsCell component detailsEngineeringCooling fluid

The invention provides a liquid cooling plate integrated box body and a battery box. The liquid cooling plate integrated box body comprises a box body and a bottom plate, the box body comprises a side plate forming an accommodating space with the bottom plate, a cooling liquid inlet and a cooling liquid outlet, and a flow channel from the cooling liquid inlet to the cooling liquid outlet is formed in the box body based on the side plates and the bottom plate. According to the liquid cooling plate integrated box body provided by the invention, the liquid cooling plate integrated box body can be compactly designed, so that the size of the battery box is reduced, meanwhile, the overall weight of the box body is reduced, the assembly process is reduced, and the production and installation efficiency is improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

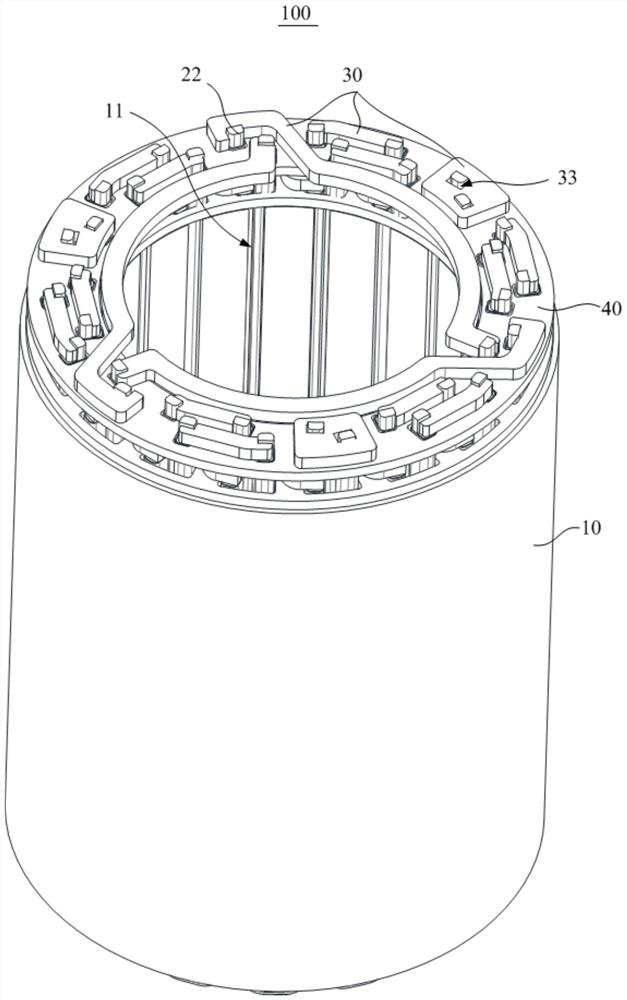

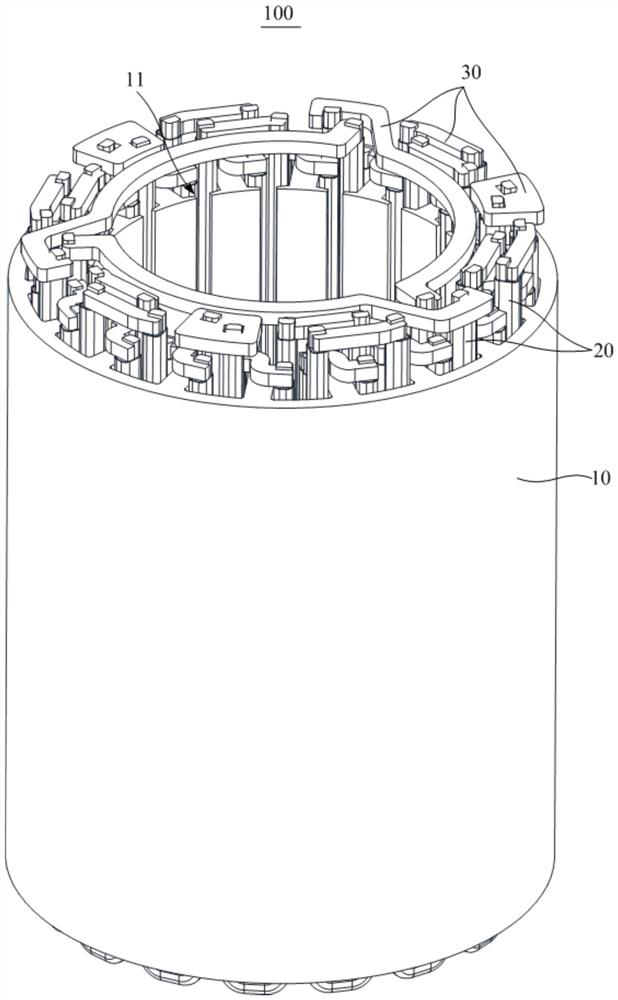

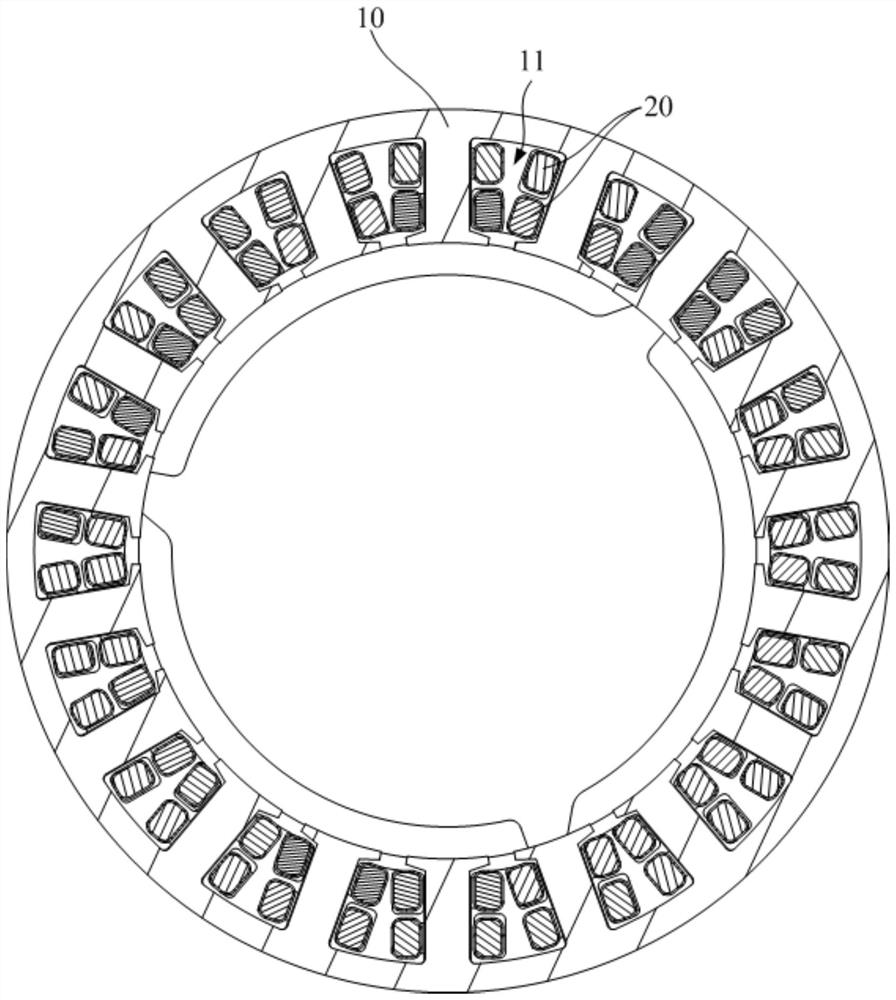

Stator assembly and motor

PendingCN112615444AImprove production and installation efficiencyIncrease the cross-sectional areaMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineCopper wire

The present invention discloses a stator assembly and a motor. The stator assembly comprises a stator iron core, a plurality of square copper wires and a plurality of special-shaped switching metal pieces, the stator iron core is annularly provided with a plurality of wire grooves extending in the axial direction of the stator iron core, and each wire groove is provided with an opening communicating with the two axial ends of the stator iron core; the square copper wires enter the wire grooves through an opening, and the wire grooves are at least provided with the square copper wires in a penetrating manner; the special-shaped switching metal pieces are arranged at the axial end parts of the stator core, and the two opposite ends of each special-shaped switching metal piece are connected to the two square copper wires respectively, so that the plurality of square copper wires are electrically conducted. According to the technical scheme, the slot fullness utilization rate of the stator core is guaranteed, and meanwhile the manufacturing and mounting efficiency of the stator assembly is improved.

Owner:SHENZHEN WEIDU INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com