Stone balustrade and making and mounting process thereof

An installation process and railing technology, which is applied to building structures, ladder structures, buildings, etc., can solve the problems of inconvenient transportation and installation, large stone railings, and low production efficiency, so as to facilitate large-scale operation and production, Remarkable effect, stone saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

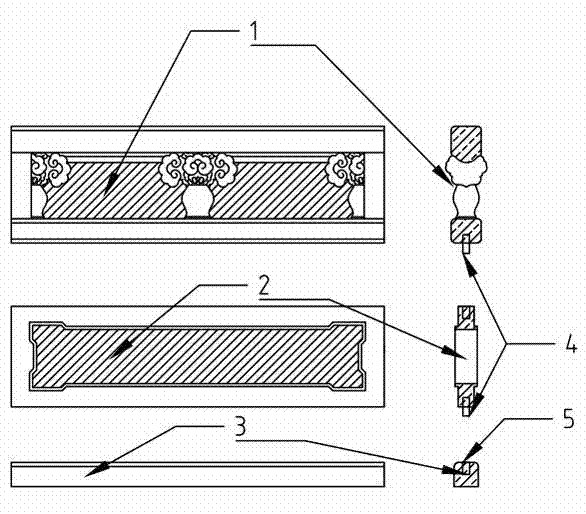

[0023] Embodiment one: Such as figure 2 As shown in the implementation schematic diagram of the stone railing of the present invention divided into three parts, the stone railing is divided into three stone components according to the overall shape structure of the stone railing in the figure, which are respectively the upper handrail part 1, the middle railing part 2 and the lower part. Mud Department 3. In practical application, the fence part 2 and the mud dragging part 3 do not need to be divided, that is, the stone railing can be divided into two stone components.

[0024] In terms of manufacturing method, first mix the ingredients according to the design drawing of the stone railing, that is, use the cutting machine to process the required specification stone; in addition, you need to prepare stone glue and tenons. Usually, the tenons can be selected but not limited to ∮12 stainless steel round tenons4 . As mentioned above, set the positioning line on the stone comp...

Embodiment 2

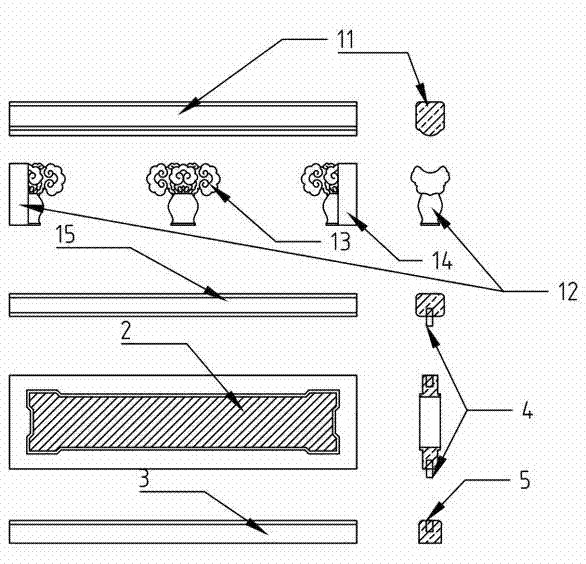

[0025] Embodiment two: Such as image 3 As shown in the implementation schematic diagram of the stone railing of the present invention divided into seven parts, according to the overall shape structure of the stone railing in the figure, the stone railing is first divided into three stone components, which are respectively the upper handrail part 1, the middle railing part 2 and the lower part. Drag mud part 3. Handrail portion 1 is further divided into multiple stone components by handrail 11, pad stone 15, vase support 13, half vase side 12, 14, etc. again.

[0026] The method of manufacture and installation are similar to those of the examples, so details are not repeated here. The benefit of present embodiment is just more obvious to handrail part division multi-block stone component. In addition to saving labor and materials, and easy installation, a railing can be made by multiple people or machined in batches, and it is not limited by angles and spaces, shortening t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com