Installation method of long-span welded ball net rack

An installation method and welding ball technology are applied in the processing of building materials, construction, building construction, etc., which can solve the problems of high construction cost and large amount of material consumption, and achieve good installation quality, simple construction, and high promotion value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The installation method of the large-span welded ball net frame provided by the present invention includes the following steps:

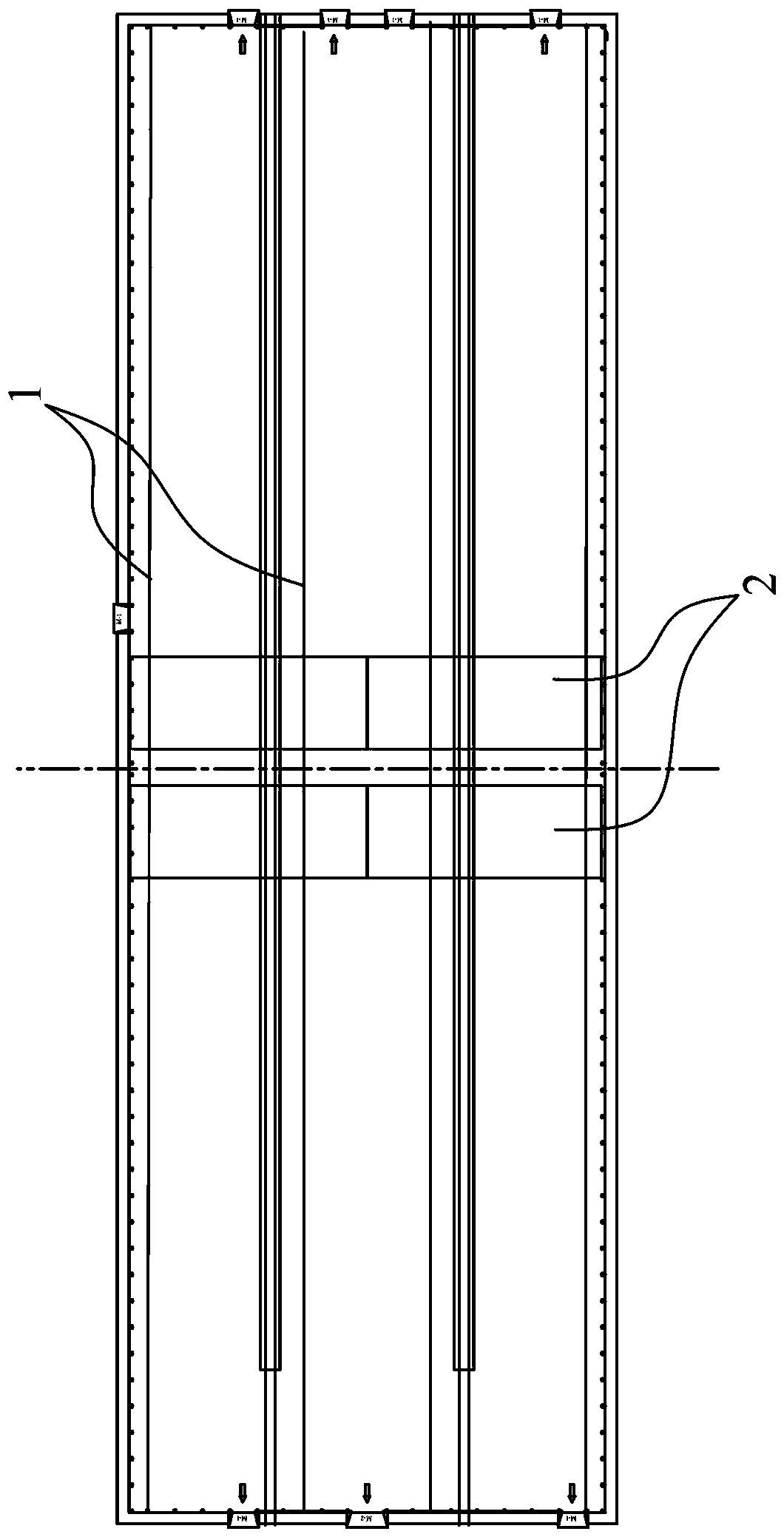

[0032] a, in such as figure 1 Four slides 1 are set in the rectangular construction area shown, which are named as the first slide, the second slide, the third slide and the fourth slide. The four slides are all parallel to the long axis of the construction area. The middle part of the construction area is provided with two arched sliding tire frames 2, and the vertical plane where the sliding tire frames 2 are located is perpendicular to the slideway 1.

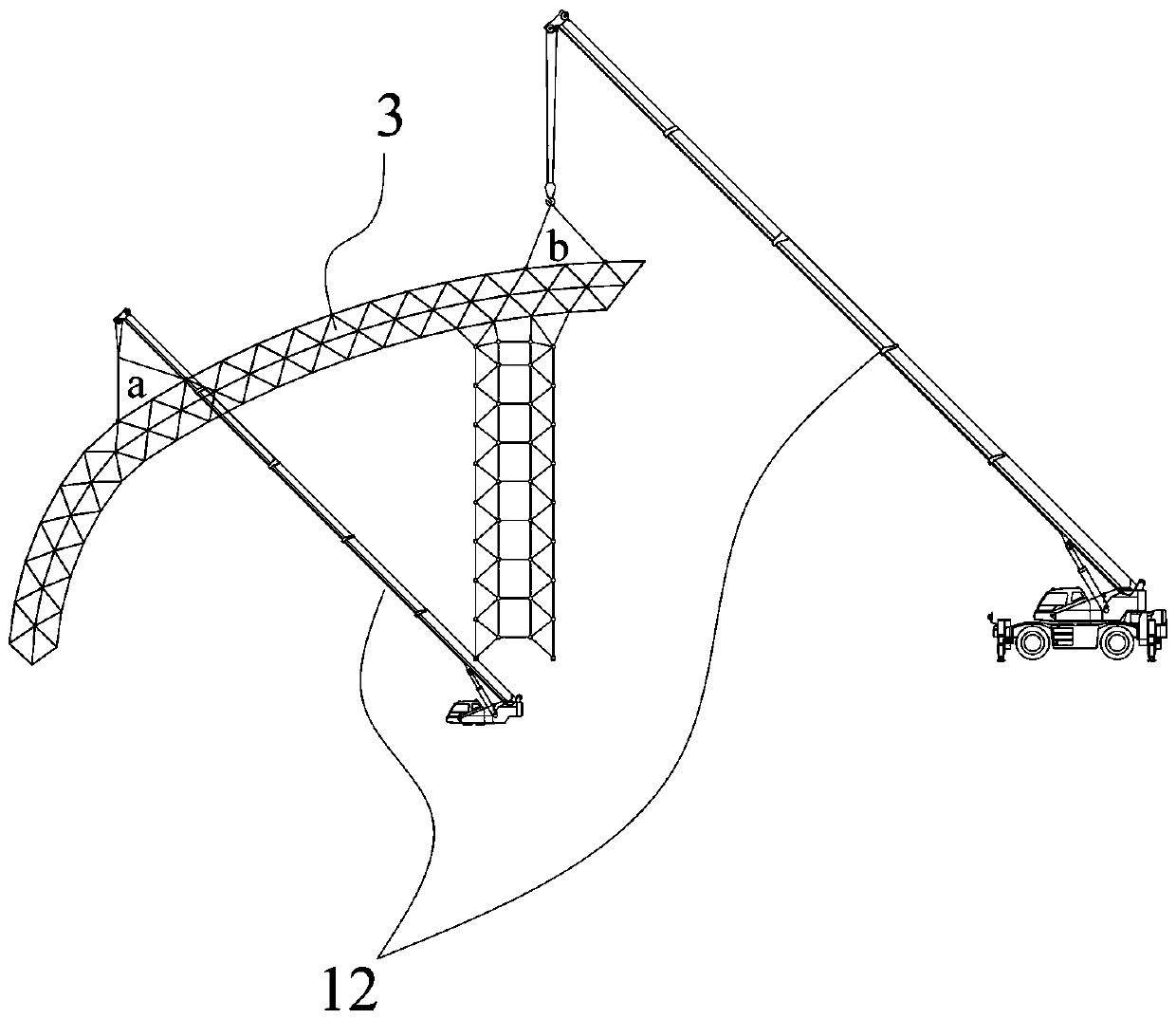

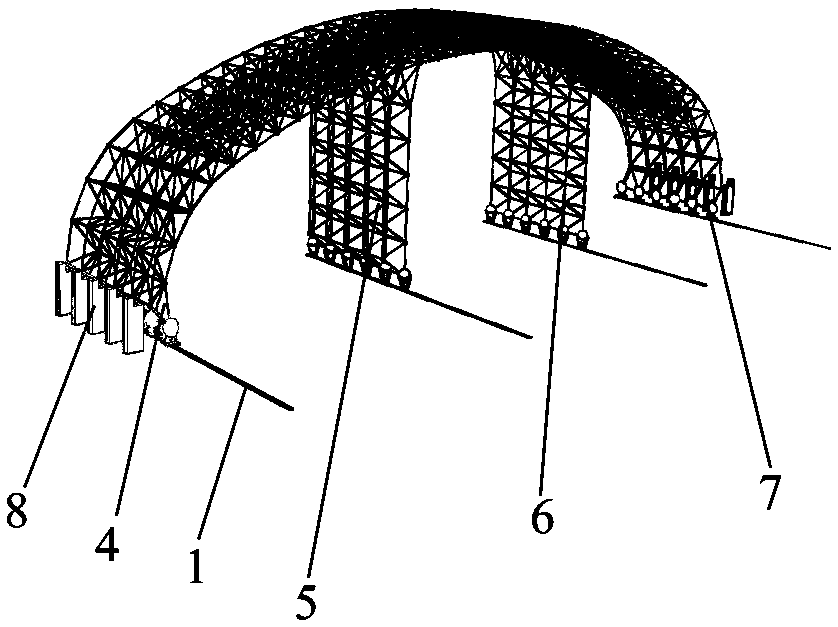

[0033] Such as image 3 As shown, the sliding tire frame 2 includes an arch frame and four supporting legs, and the four supporting legs respectively correspond to four slideways, which are successively named as the first supporting leg 4, the second supporting leg 5, the third supporting leg 6 and the fourth supporting leg 7. There are rollers at the bottom of each support leg, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com