Airplane cabin door intelligent installation method based on AGV intelligent parallel robot

An installation method and robot technology, applied in the field of robot systems, can solve the problems of lack of safety monitoring measures, low degree of flexibility, complicated attitude adjustment process, etc., and achieve the effects of improving production and installation efficiency, high positioning accuracy, and large adjustment stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

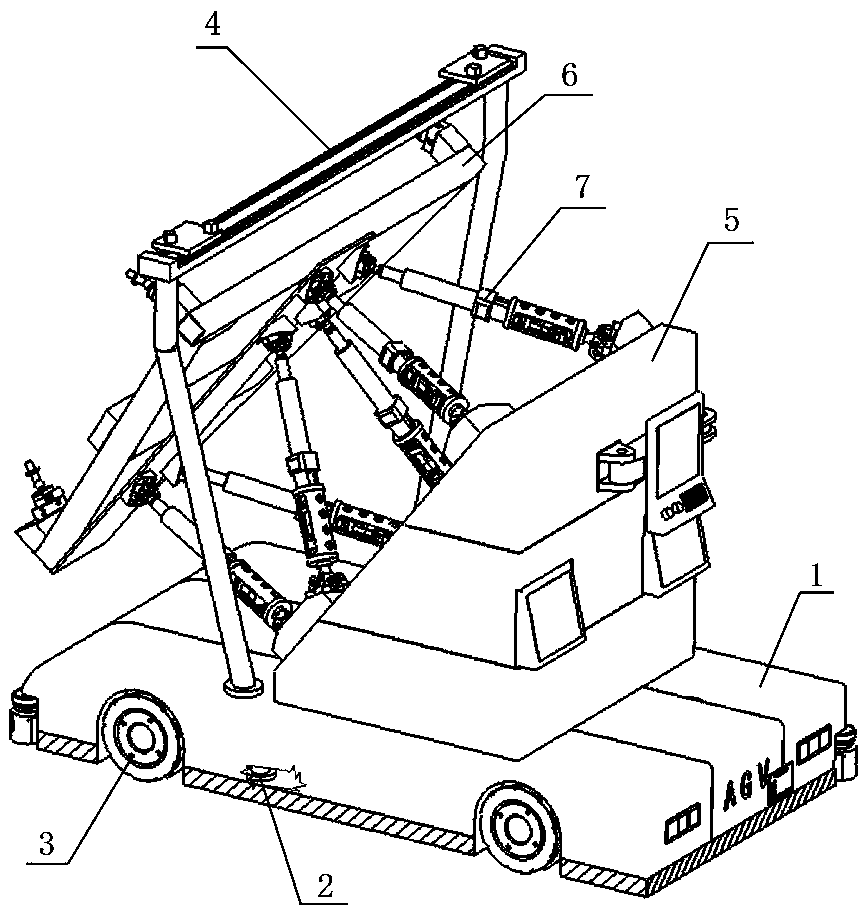

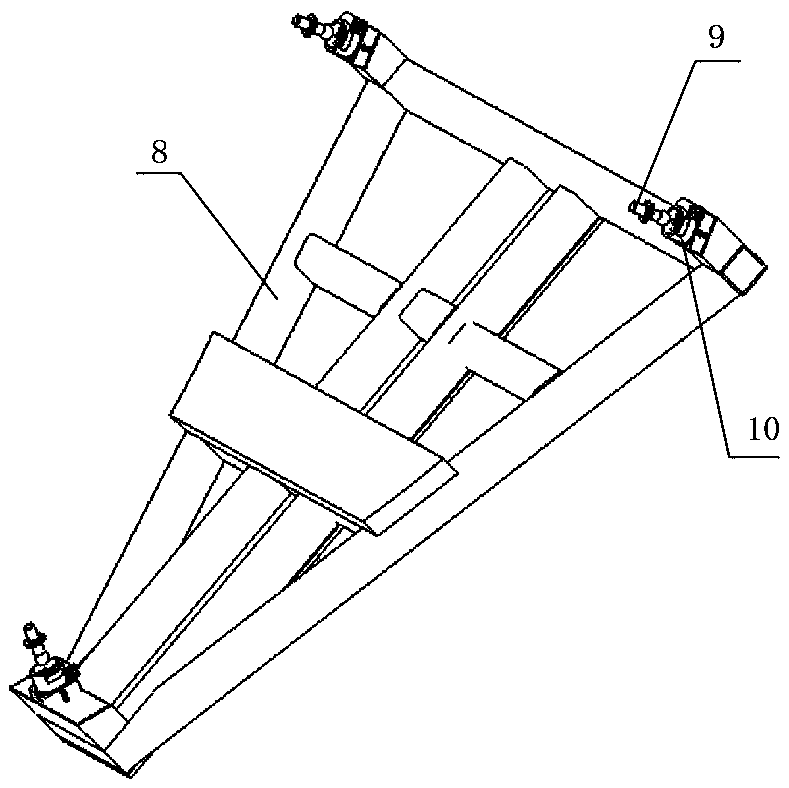

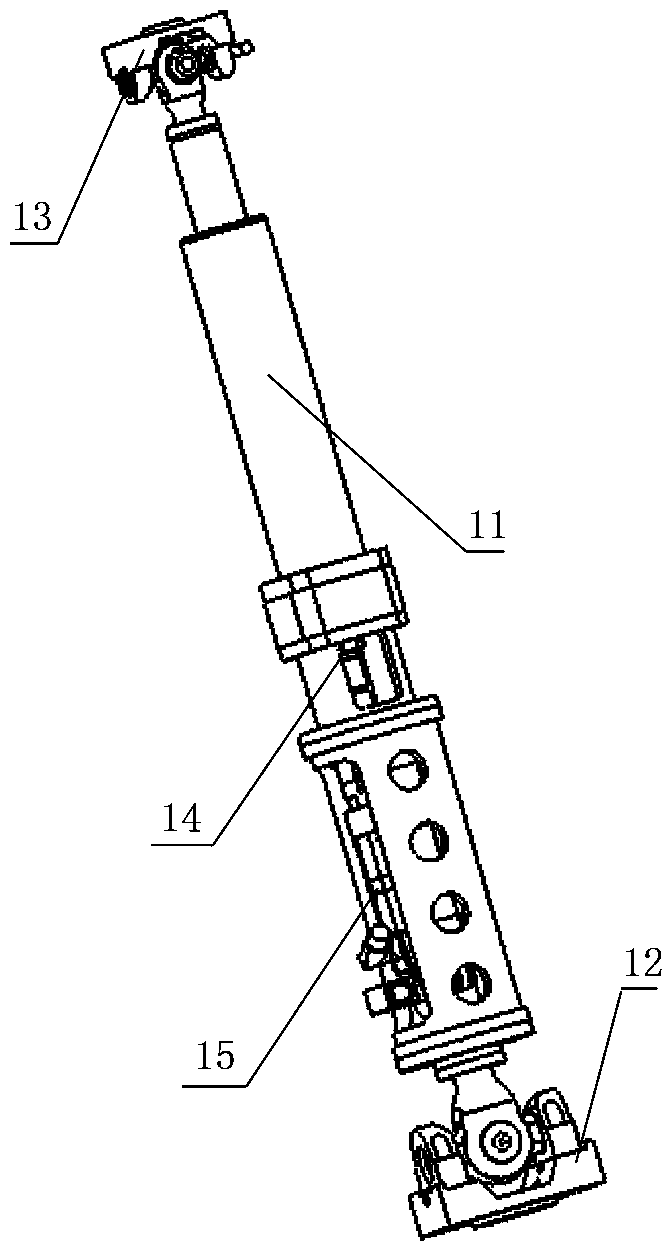

[0020] The structure of the AGV intelligent parallel robot described in the present invention is as follows: figure 1 As shown, it includes car body 1, support assembly 2, mecanum wheel 3, camera adjustment mechanism 4, fixed platform 5, motion platform 6, electric servo telescopic rod 7; four mecanum wheels 3 are installed on the car body 1 On both sides, three support assemblies 2 are arranged in the car body 1, of which one is arranged in the center of the front part of the car body, and two are symmetrically arranged in the rear part of the car body; the camera adjustment mechanism 4 is fixedly connected to the top of the car body 1, and the camera adjustment mechanism 4 is Guide rails are provided, and two camera connection seats are arranged on the guide rails, the connection seats hold the camera and can change positions along the guide rails; the fixed platform 5 is fixedly connected to the car body 1, and the fixed platform 5 is an approximate right-angled prism struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com