Six-freedom-degree airplane large component digital assembling parallel robot system

A robot system and large component technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of difficult production and assembly, low assembly precision, and high assembly cost, and achieve poor adaptability, reduce workload, and improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

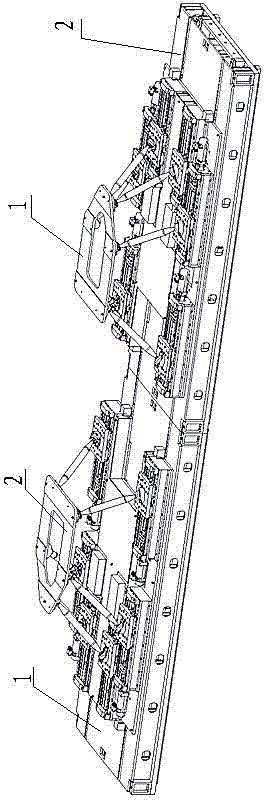

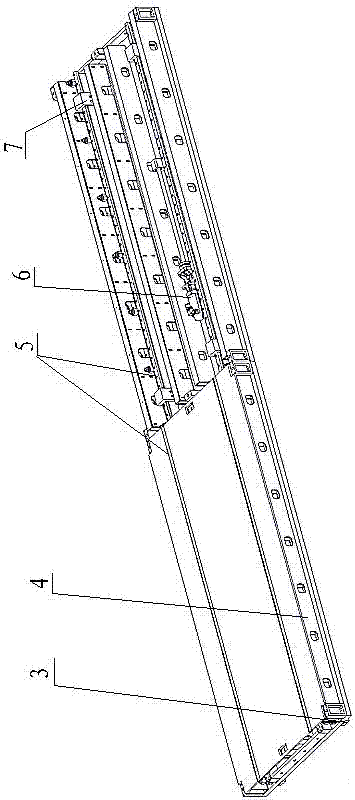

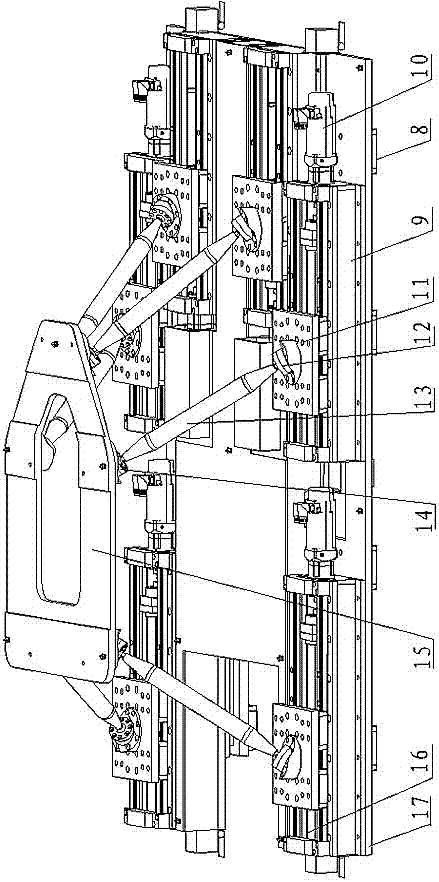

[0014] The multi-degree-of-freedom space large parts rapid assembly parallel robot system structure of the present invention is as follows: figure 1 As shown, it is a 6-DOF simulation space rapid assembly system for large parts, including two sets of fixed base components 1 and two sets of parallel linkage platform components 2 . like figure 2 As shown, each set of fixed base components 1 includes a base 4, an X-axis linear guide 5, and an X-axis servo drive system 6; as image 3 As shown, each group of parallel linkage platform components 2 includes a base plate 17, a support base 9, an X1-axis servo drive system 10, a ball joint support base 11, an upper ball joint 14, a lower ball joint 12, a support rod 13, an attitude adjustment platform 15, The X1-axis linear guide rail 16 and the X-axis guide rail slider 8; the bottom of the base 4 is equipped with an adjustable foot 3, and the height of the base 4 can be adjusted by adjusting the foot 3 to ensure that the two groups ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com