Parallelism detection method for contact surfaces of sector plate of coiling machine

A contact surface, fan-shaped plate technology, applied in the field of rapid detection in mass production, can solve the problems of long assembly cycle, no advantage in mass production, and a lot of time, and achieve the effect of reducing difficulty and improving production and installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

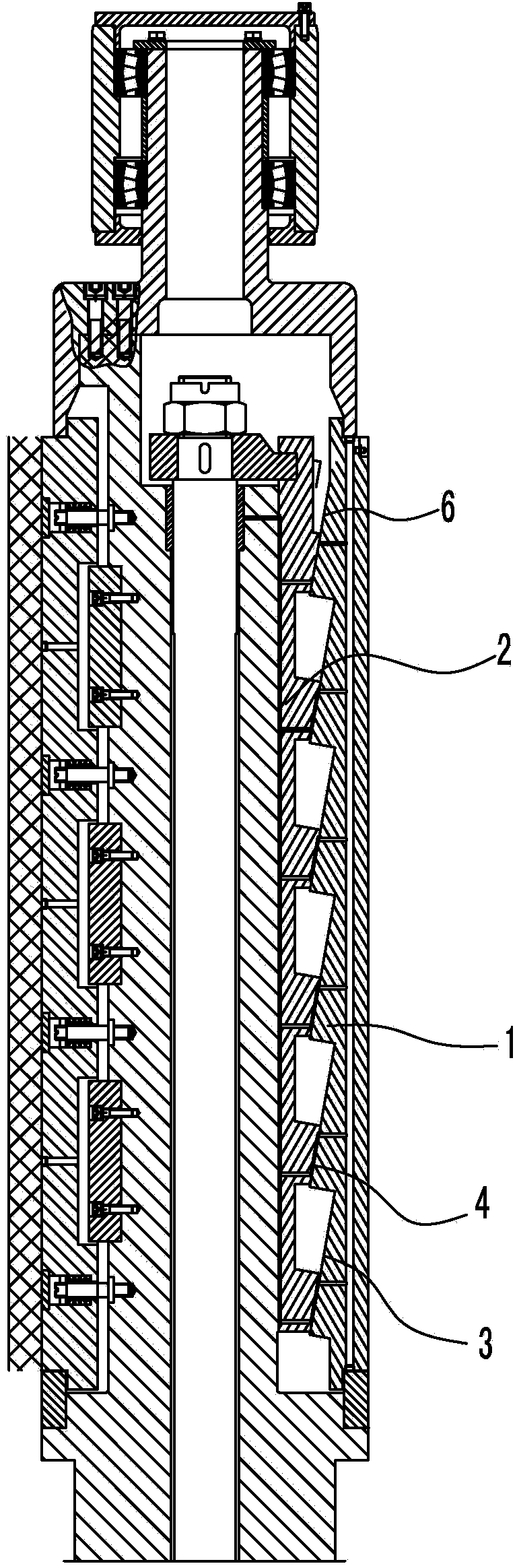

[0025] Example: A detection method for the parallelism of the contact surface of the fan-shaped plate of the coiler

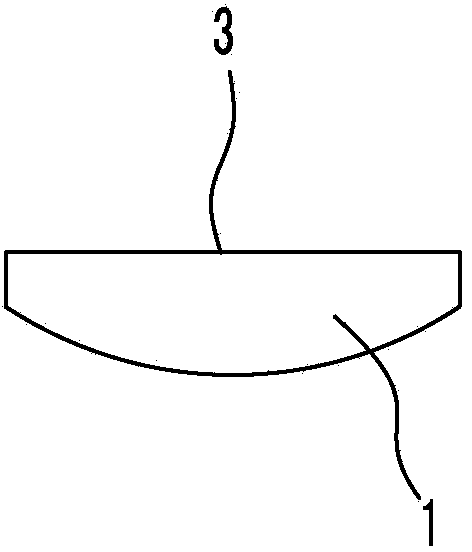

[0026] The outer peripheral surface of the fan-shaped plate 1 is an arc surface, the inner side is the assembly side, and the assembly side is stepped in the axial direction of the arc surface. This step is composed of several steps, and each step has a contact surface. Next, the fan-shaped plate 1 is arranged on a pyramid shaft 2 along the circumference of the pyramid shaft 2 , and the contact surface is attached to the corresponding assembly surface 4 on the pyramid shaft 2 .

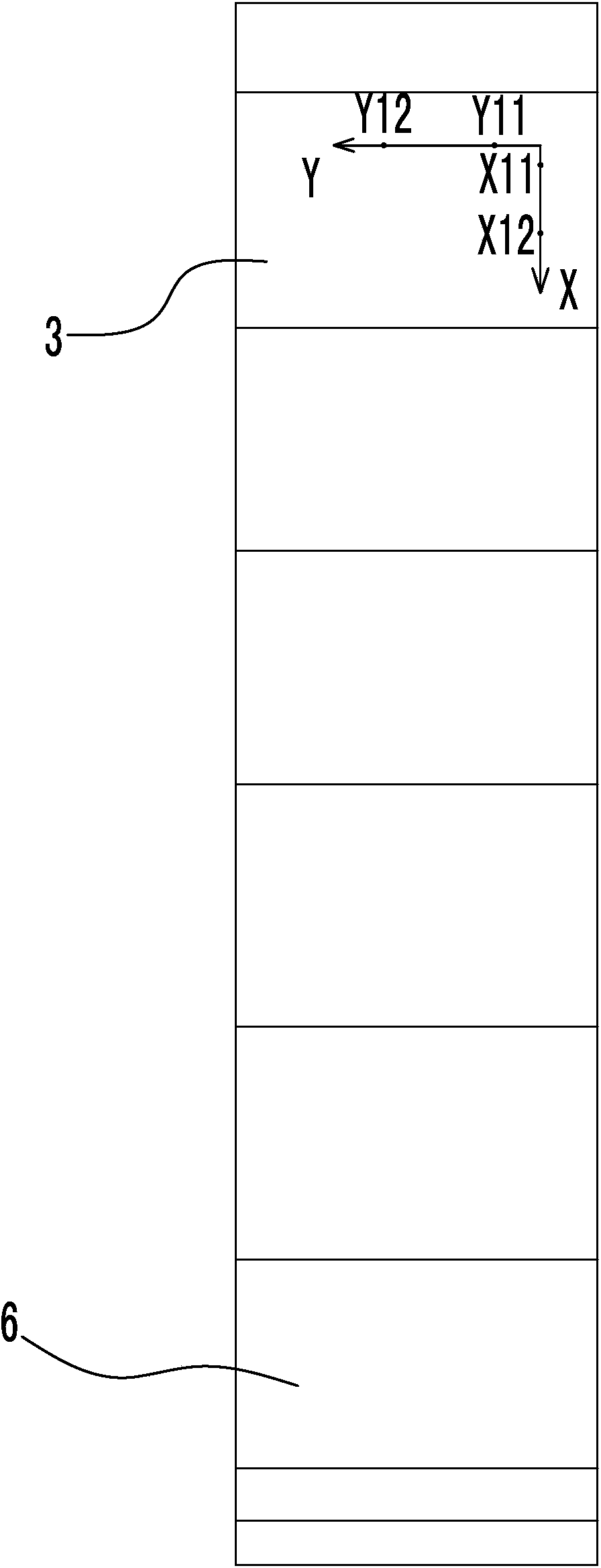

[0027] For example, detecting the parallelism between the first contact surface 3 and the sixth contact surface 6 on the sector plate 1 includes the following steps:

[0028] The first step is to set a datum reference plane 5 , position and arrange the fan-shaped plate 1 relative to the datum reference plane 5 , and make the sixth contact surface 6 adhere to the datum reference plane 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com