Dry hang structure and decorative finish system

A dry-hanging and veneer technology, used in building construction, covering/lining, construction, etc., can solve the problems of cumbersome production process, difficult overall shape adjustment or disassembly, and large flatness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

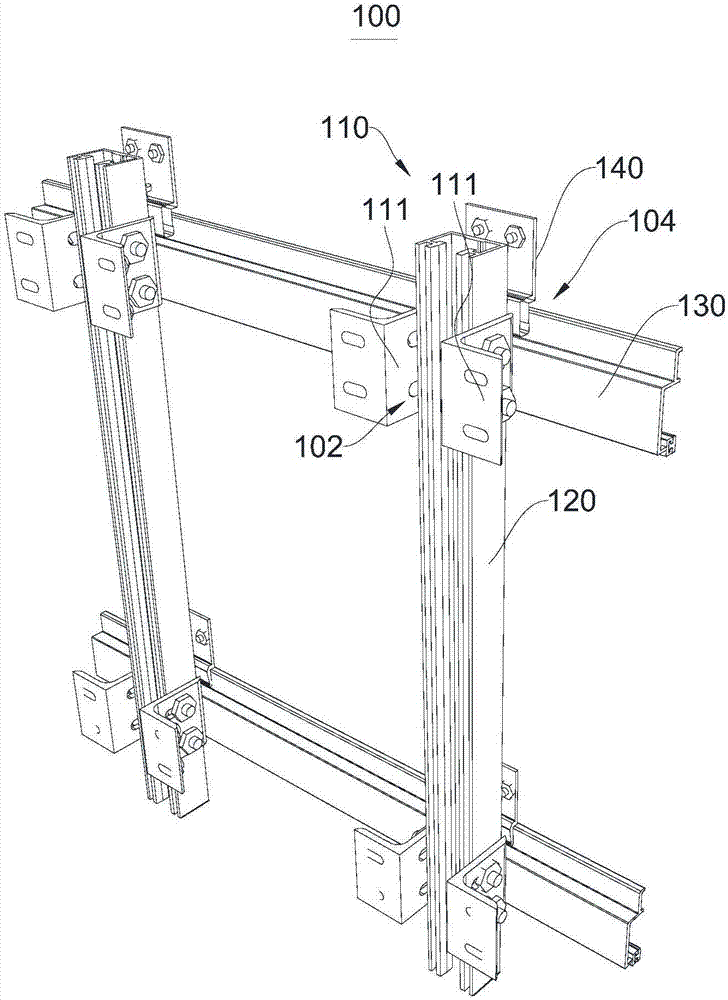

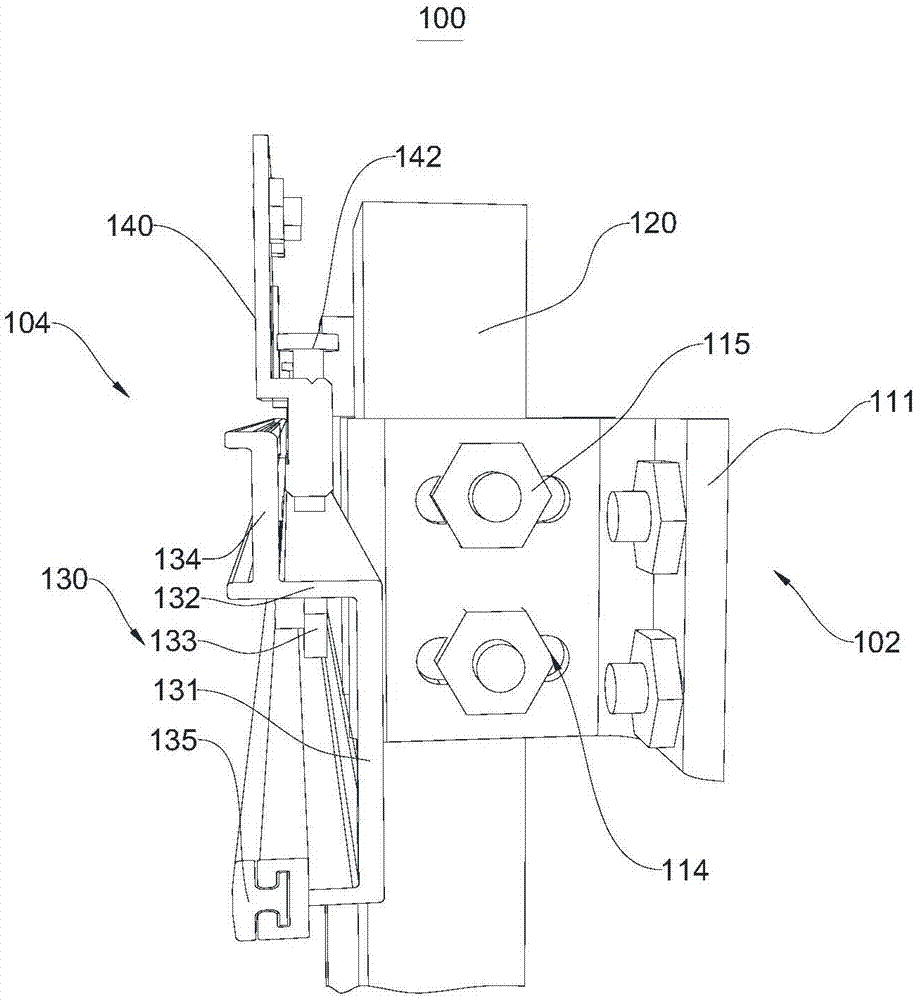

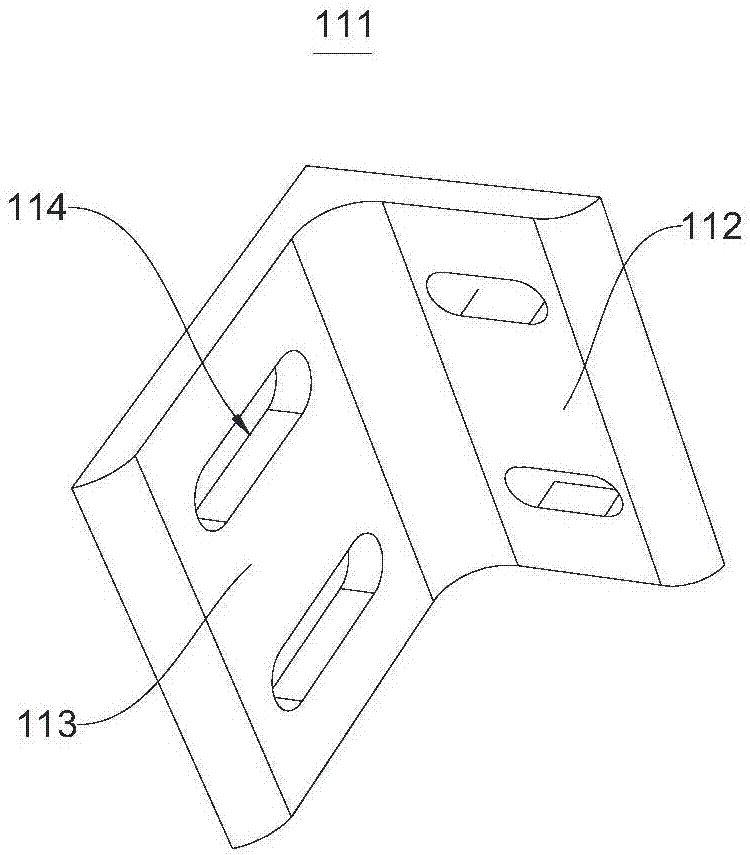

[0033] figure 1 It is a structural schematic diagram of the first viewing angle of the dry-hanging structure 100 in the embodiment of the present invention; figure 2 It is a structural schematic diagram of the second viewing angle of the dry hanging structure 100 in the embodiment of the present invention. Please refer to figure 1 with figure 2 , the present embodiment provides a dry hanging structure 100, which is used to be fixed on the wall and hang the decorative panel 210 (see Figure 4 ), the dry-hanging structure 100 has a first side 102 fixedly connected to a wall (not shown in the figure) and a second side 104 for hanging a veneer 210 . In this embodiment, the dry hanging structure 100 includes a plurality of first keels 120 extending in the vertical direction, a plurality of second keels 130 extending in the horizontal direction, and a connection for fixing the first keels 120 to the wall. part 110 and the fastener 140 used to connect the second keel 130 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com