Lap joint bar type prestressed two-way laminated plate and construction method

A prestressed and laminated slab technology, applied to floors, structural elements, building components, etc., can solve the problems of reducing slab thickness, rib height, and reducing installation work efficiency, so as to reduce the structural weight, expand the service radius, and increase installation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

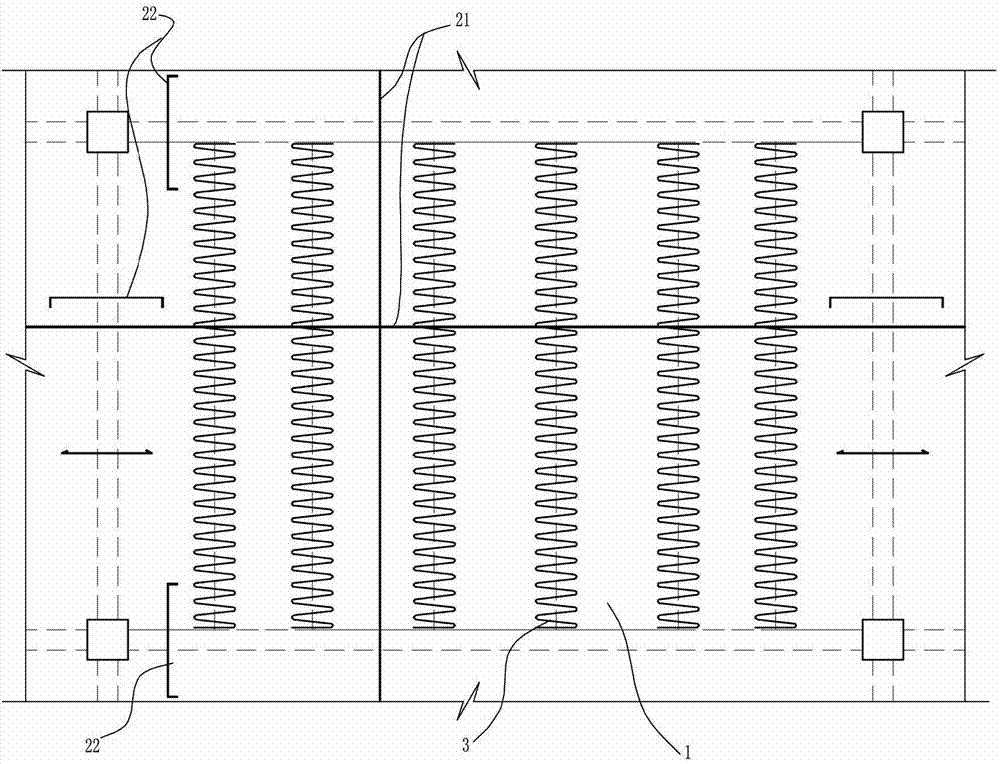

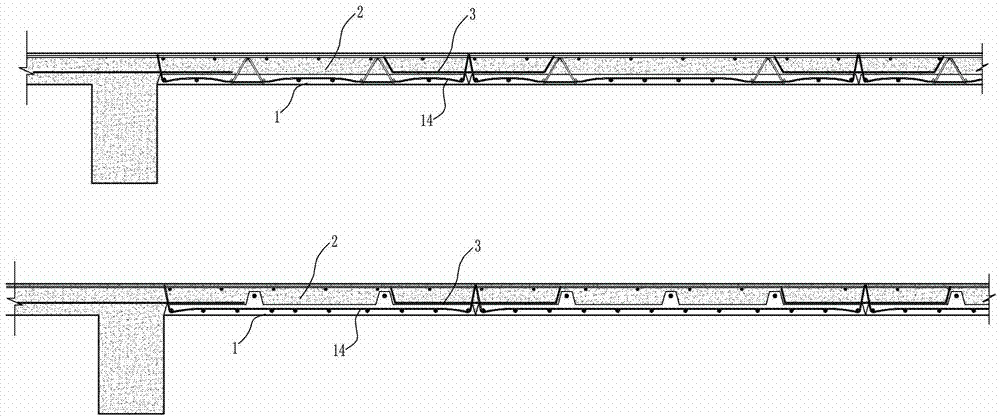

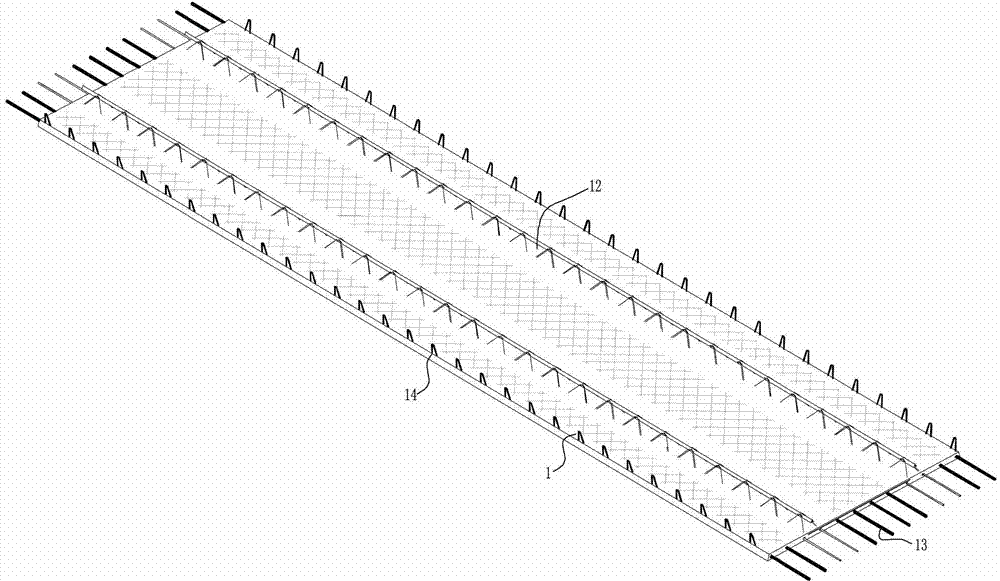

[0033] see Figure 1 to Figure 6 , The embodiment of a kind of prestressed two-way laminated slab with lap ribs provided in the present invention includes at least three prefabricated prestressed thin slabs 1 , a post-cast concrete layer 2 and slab seam lapped steel bars 3 . The prefabricated prestressed thin slab 1 is a large-width slab with ribs 11 or steel bar truss 12, and the overlapping steel bars 3 are continuous S-shaped, horizontally laid on the upper surface of the adjacent prefabricated thin slab across the slab seam, And buried in post-cast concrete. The laminated slabs are usually used for floors with large spans, but the transportation and hoisting of prefabricated slabs with large lengths requires that the prefabricated slabs must have certain rigidity and strength. Prefabricated slabs with ribs 11 or steel trusses 12 can Improve the rigidity and strength of the slab, thereby reducing the thickness of the prefabricated slab concrete. The use of large-width pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com