Lubricating structure for bevel gear bearing

A lubricating structure and bevel gear technology, which is applied in gear lubrication/cooling, bearings, roller bearings, etc., can solve problems such as poor lubrication effect of bevel gear bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

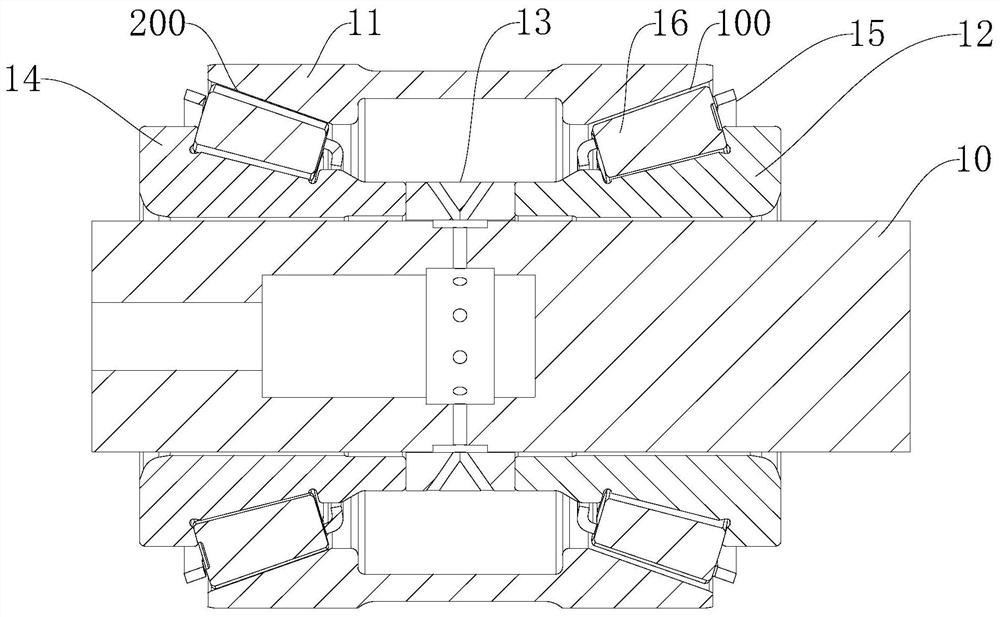

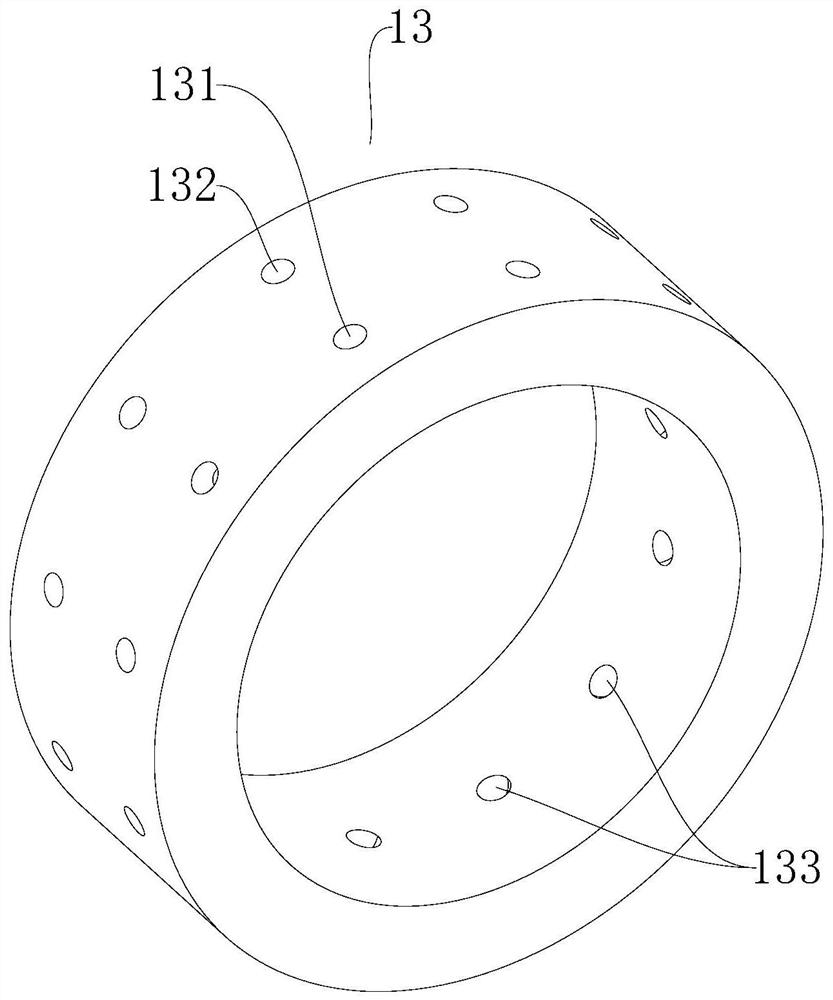

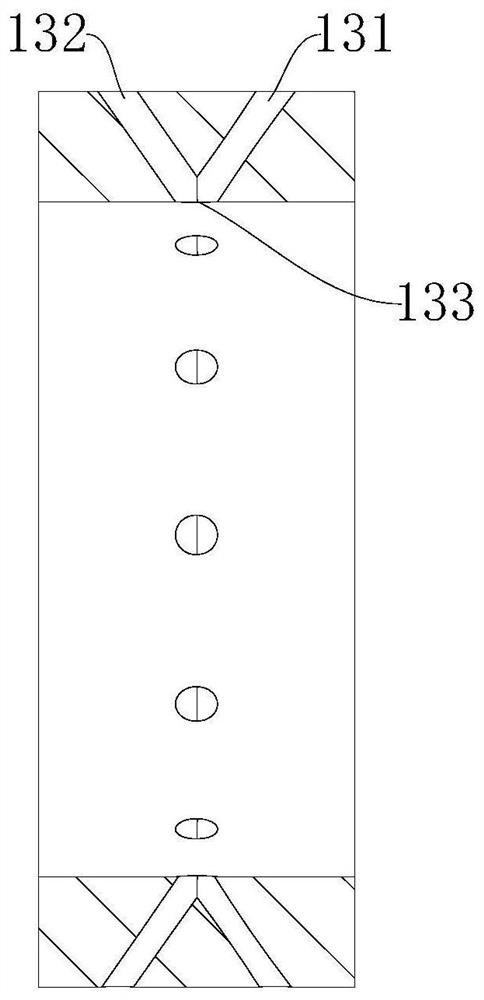

[0037] A lubricating structure for bevel gear bearings, comprising a bevel gear shaft 10, bearings are installed on the bevel gear shaft 10, the bearings include a bearing outer ring 11, a front bearing inner ring 12 and a rear bearing inner ring 14, the bearings include a front bearing and Rear bearing, front bearing and rear bearing are provided with a bearing outer ring 11, form front raceway 100 between bearing outer ring 11 and front bearing inner ring 12, and front raceway 100 is ring tapered raceway. A rear raceway 200 is formed between the bearing outer ring 11 and the rear bearing inner ring 14, and the rear raceway 200 is also a ring-tapered raceway. On the bevel gear shaft 10, an oil throwing ring 13 is installed, and the oil throwing ring 13 is located between the front bearing inner ring 12 and the rear bearing inner ring 14. 14 contact connections, the outer circumference diameter of the oil throwing ring 13 is equal to the inner end outer circumference diameter ...

Embodiment 2

[0047] Embodiment 2 has basically the same features as Embodiment 1, except that the diameter of the front oil pump hole 131 and the rear oil pump hole 132 are both 0.75 mm. The diameter of the oil throwing hole 133 is 2.75 mm.

Embodiment 3

[0049] Embodiment 3 has basically the same features as Embodiment 1, except that the diameter of the front oil pump hole 131 and the rear oil pump hole 132 are both 1 mm. The diameter of the oil throwing hole 133 is 5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com