Valve body with internal adjustable lifting sealing mechanism

A closed mechanism and adjustable technology, applied in the direction of lift valve, valve details, multi-way valve, etc., can solve the problems of high maintenance and use costs, inability to quickly disassemble according to needs, inability to freely adjust the flow rate of the delivery pipe and the order of closure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

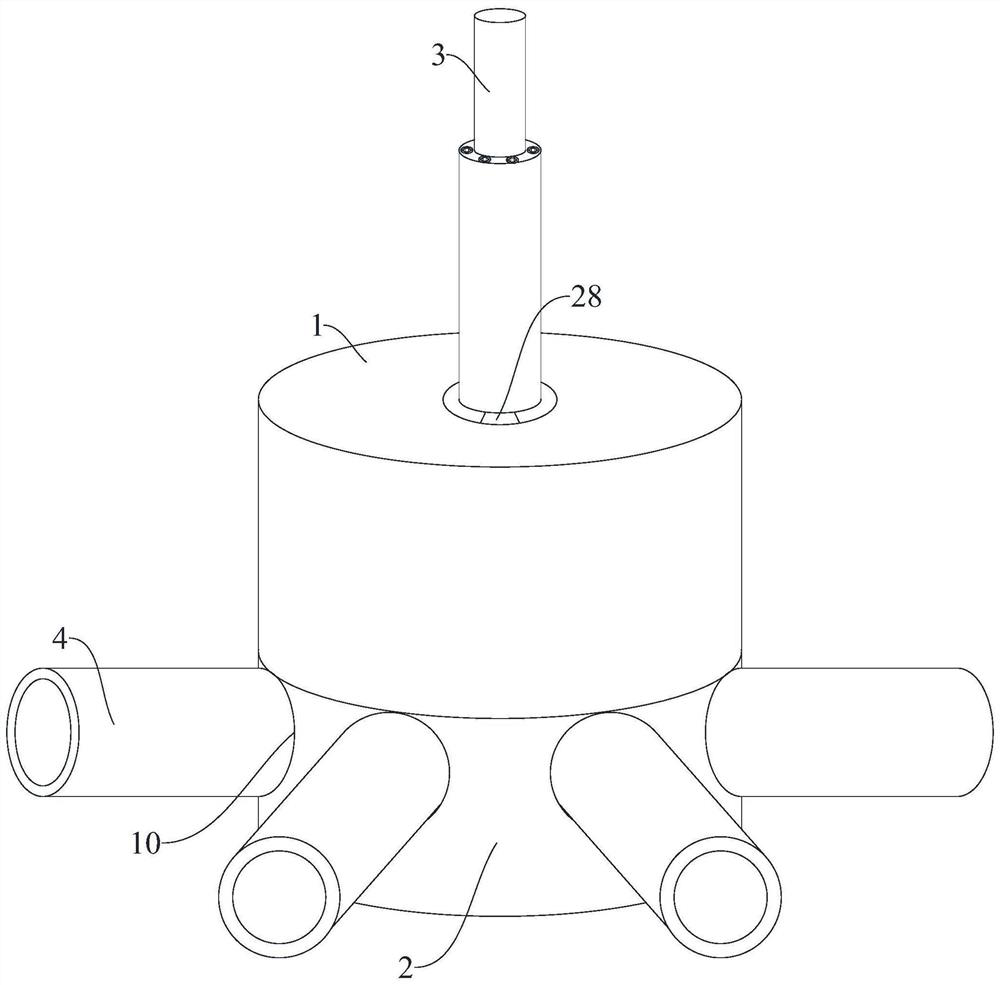

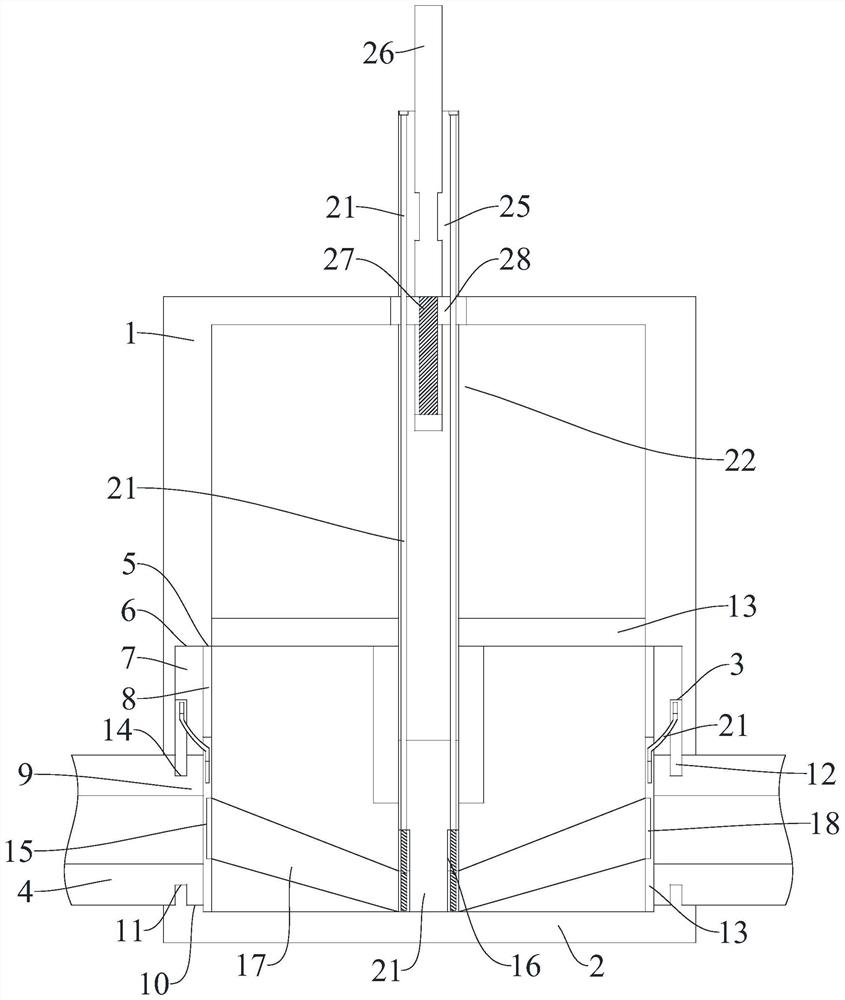

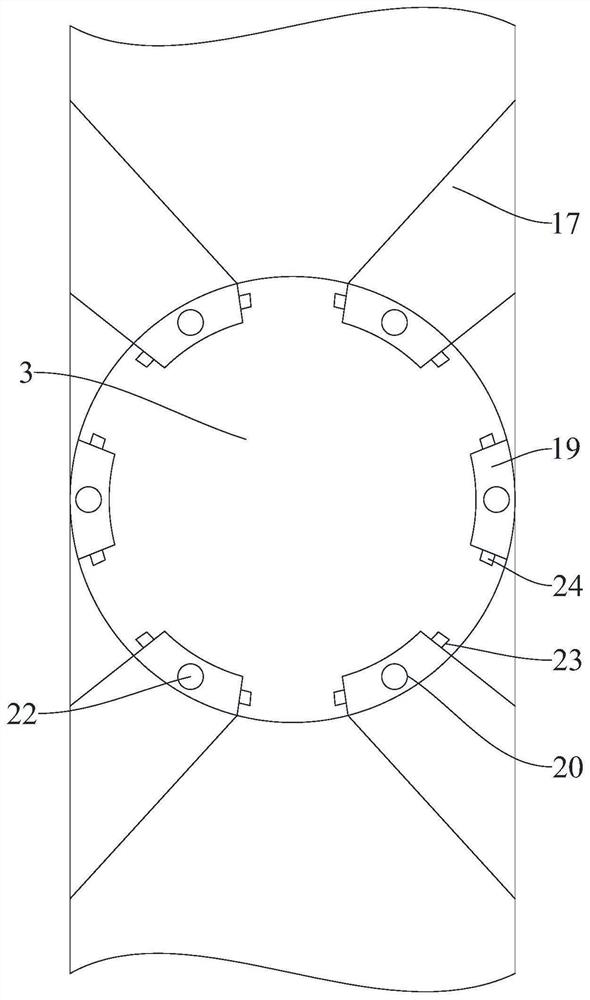

[0027] Embodiment: first insert the internal connecting pipe 9 on the lateral conveying pipe 4 into the arc-shaped assembly groove 10 and the arc-shaped limit groove 11, then thread the upper valve casing 1 onto the lower valve casing 2, and align the arc-shaped assembly groove 10 and the upper opening of the arc-shaped limiting groove 11 are closed, and then the top control lever 3 is rotated, and the elastic lifting locking mechanism is stuck in the position of the inner connecting pipe 9 corresponding to the arc-shaped limiting groove 11, and the closing limit is completed, and at the same time, the upper valve The shell 1 and the lower valve shell 2 are fixed and cannot be rotated and separated.

[0028] Further, in order to facilitate lateral assembly, the connecting end of the lateral conveying pipe 4 has an internal connecting pipe 9 with an integrated structure. The arc fitting groove 10 and the arc limiting groove 11 of the connecting pipe 9 .

[0029] Further, in or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com