Axial force testing method and device of squirrel-cage elastic support, electronic equipment and medium

A test method and technology of axial force, which is applied in the direction of measuring device, engine test, machine/structural component test, etc., and can solve problems such as rotor axial force and difficult coupling signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be described in detail below with reference to the accompanying drawings and embodiments.

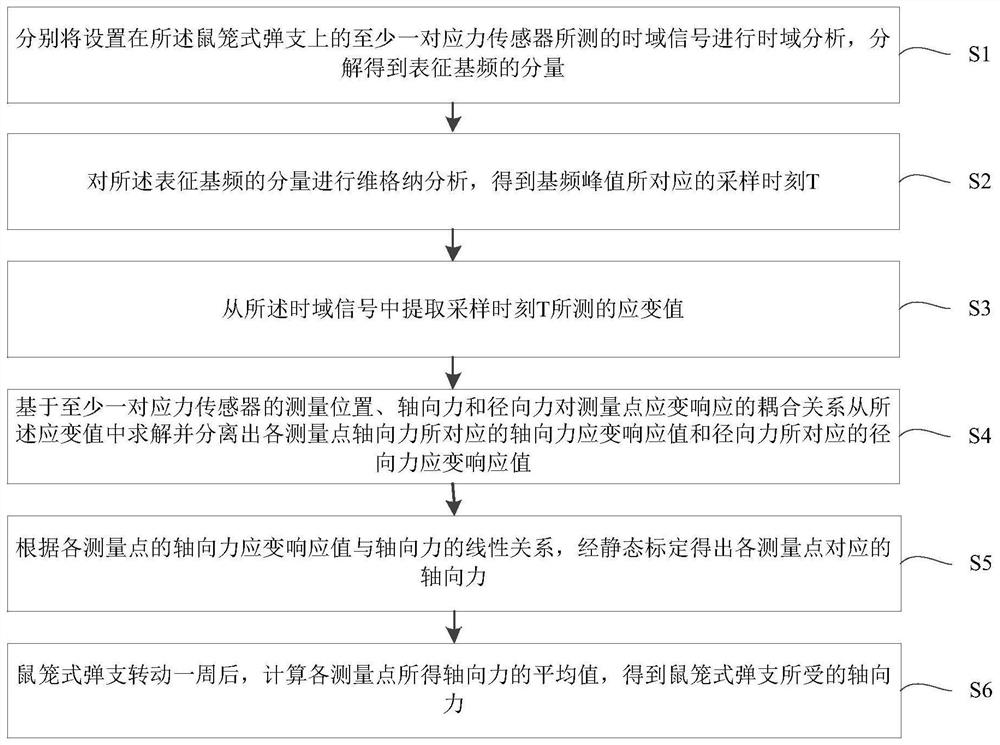

[0056] refer to figure 1 , the preferred embodiment of the present application provides a method for testing the axial force of a squirrel-cage spring, comprising steps:

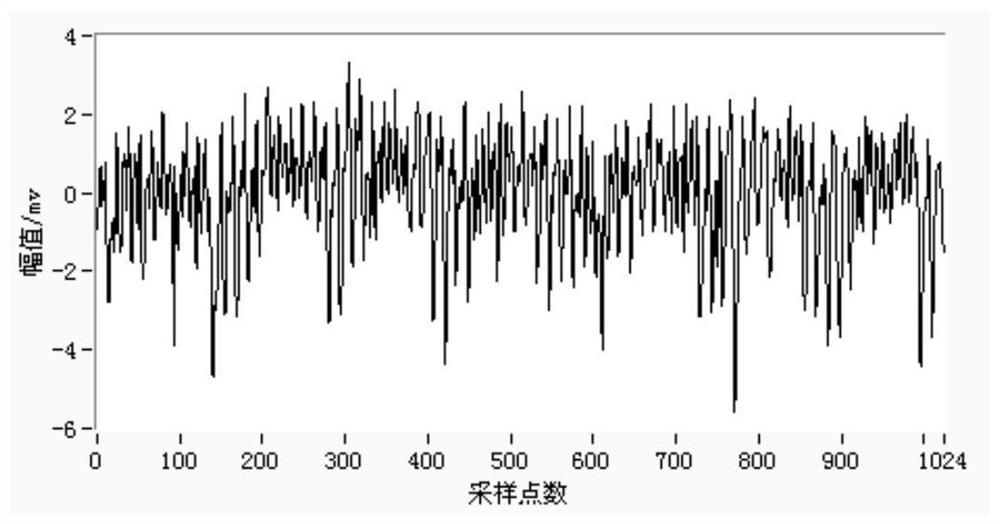

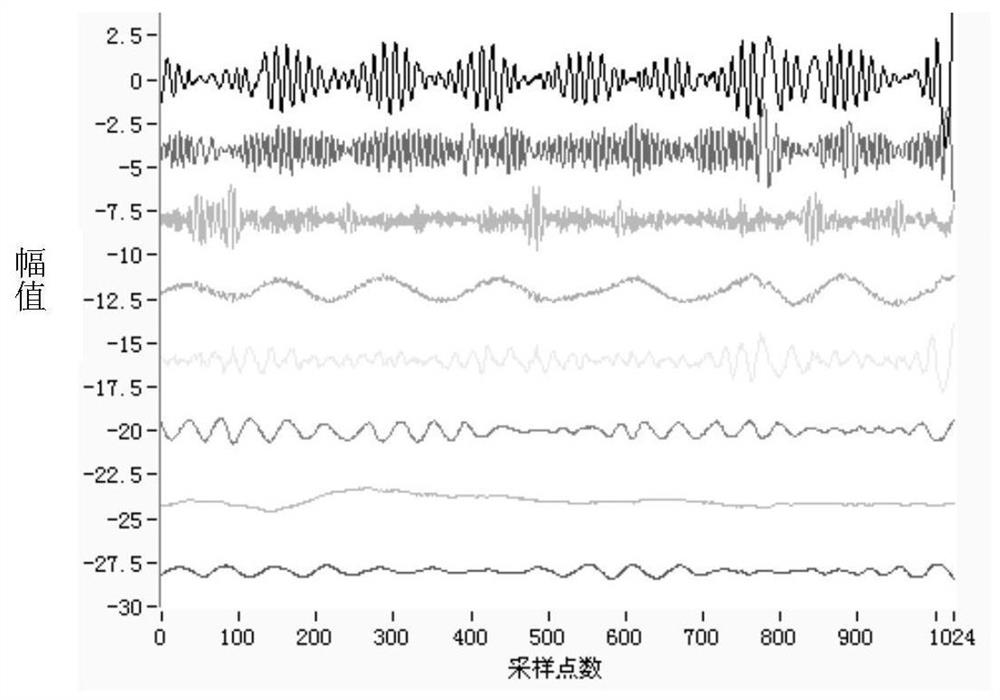

[0057] S1. Time-domain signals measured by at least one pair of stress sensors (such as figure 2 Shown) for time-domain analysis, decomposed to obtain the components that characterize the fundamental frequency (such as image 3 shown), wherein the at least one pair of stress sensors is located on the same cross-section of the squirrel-cage spring, and each pair of stress sensors is arranged symmetrically around the axis of the squirrel-cage spring;

[0058] S2. Perform Wigner analysis on the component representing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com