Display panel, preparation method thereof and display device

A display panel and surface structure technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as high production costs, printing ink material consumption, and high printing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

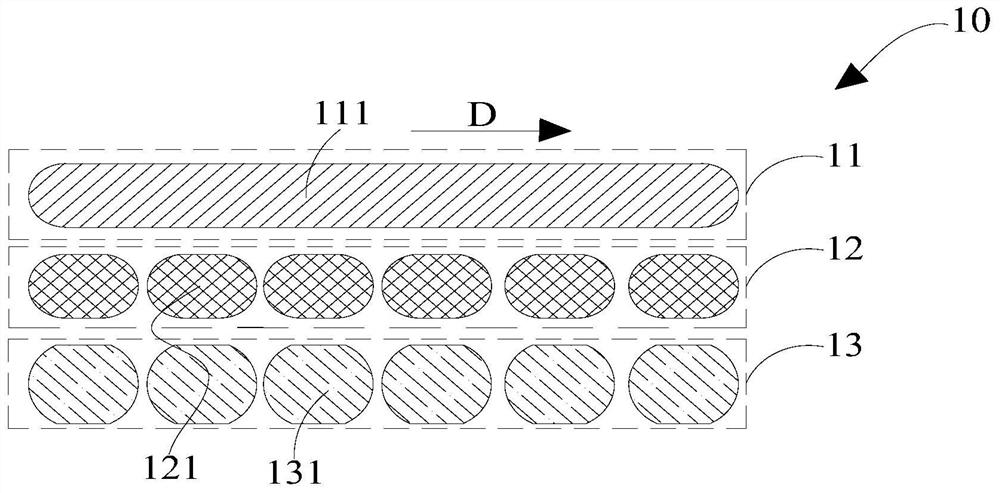

[0036] Such as figure 1 As shown, it is a schematic diagram of the pixel structure of the display panel provided in the first embodiment of the present application; wherein, the display panel includes at least one pixel unit 10, and each of the pixel units 10 includes first sub-pixels 11 with different light emitting colors, The second sub-pixel 12 and the third sub-pixel 13, the first sub-pixel 11, the second sub-pixel 12 and the third sub-pixel 13 are arranged in sequence along the first direction;

[0037] Wherein, the first sub-pixel 11 is a continuous linear structure 111, the third sub-pixel 13 includes a plurality of third sub-pixel blocks 131 arranged at intervals along the second direction D, and the second sub-pixel 12 includes A plurality of second sub-pixel blocks 121 arranged at intervals in a second direction D, where the second direction D is perpendicular to the first direction.

[0038] Optionally, in this embodiment of the present application, the light emit...

Embodiment 2

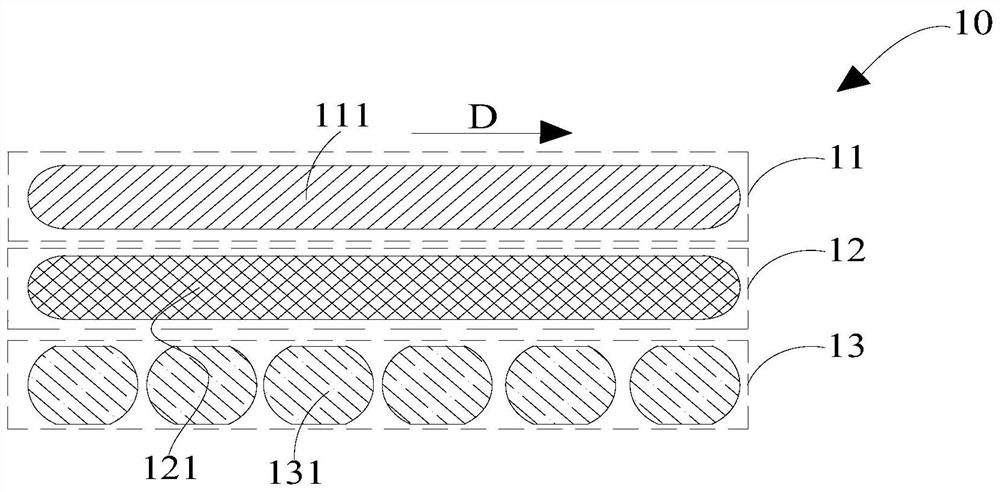

[0048] Such as figure 2 As shown, it is a schematic diagram of the pixel structure of the display panel provided by the second embodiment of the present application; wherein, the difference between the second embodiment of the present application and the first embodiment of the present application is only that:

[0049] The first sub-pixel 11 is a continuous linear structure 111, the second sub-pixel 12 is a continuous linear structure 121, and the third sub-pixel 13 includes a plurality of third sub-pixel blocks arranged at intervals along the second direction 131.

[0050] Optionally, in this embodiment of the present application, the light emitting color of the first sub-pixel 11 is red, the light emitting color of the second sub-pixel 12 is green, and the light emitting color of the third sub-pixel 13 is blue .

Embodiment 3

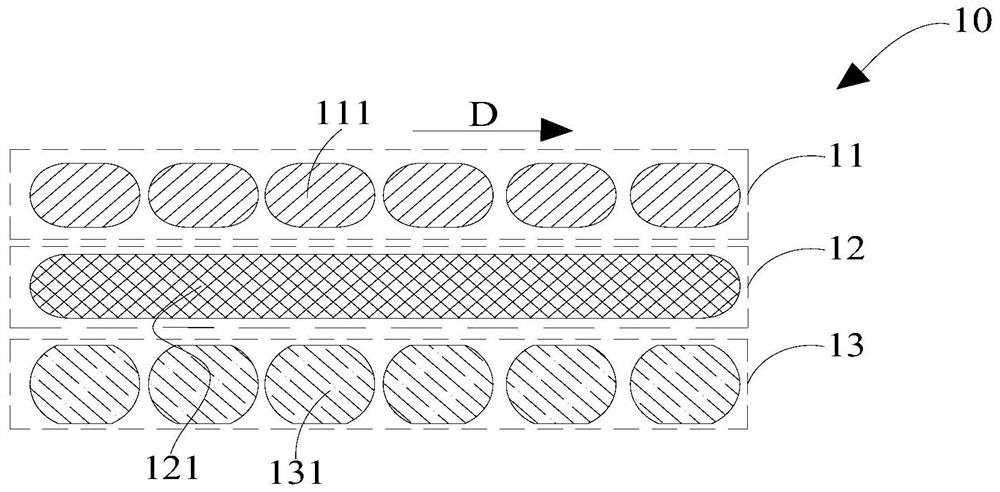

[0052] Such as image 3 As shown, it is a schematic diagram of the pixel structure of the display panel provided by the third embodiment of the present application; where, the difference between the third embodiment of the present application and the first embodiment of the present application is only that:

[0053] The first sub-pixel 11 includes a plurality of first sub-pixel blocks 111 arranged at intervals along the second direction D, and the third sub-pixel 13 includes a plurality of third sub-pixel blocks 131 arranged at intervals along the second direction D, The second sub-pixel 12 is a continuous linear structure 121 .

[0054] Optionally, in this embodiment of the present application, the light emitting color of the first sub-pixel 11 is red, the light emitting color of the second sub-pixel 12 is green, and the light emitting color of the third sub-pixel 13 is blue .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com