Netting hydrodynamic test device and method

A test device, hydrodynamic technology, applied in the field of netting hydrodynamic test device, can solve the time-consuming and interference problems of changing nets, and achieve the effect of compact structure, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

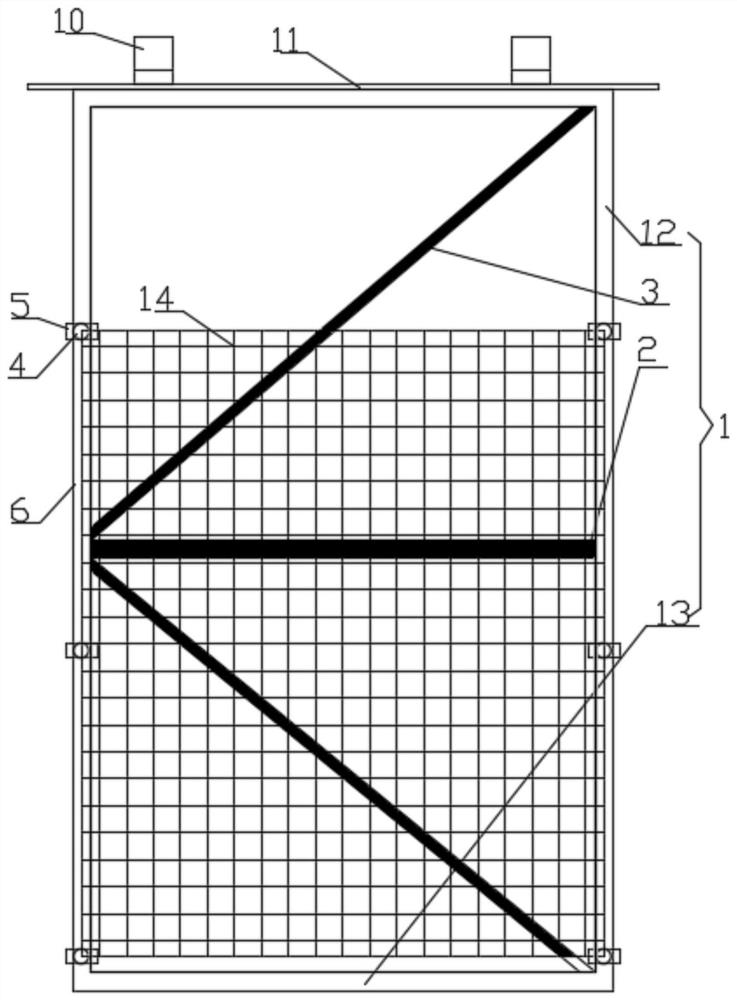

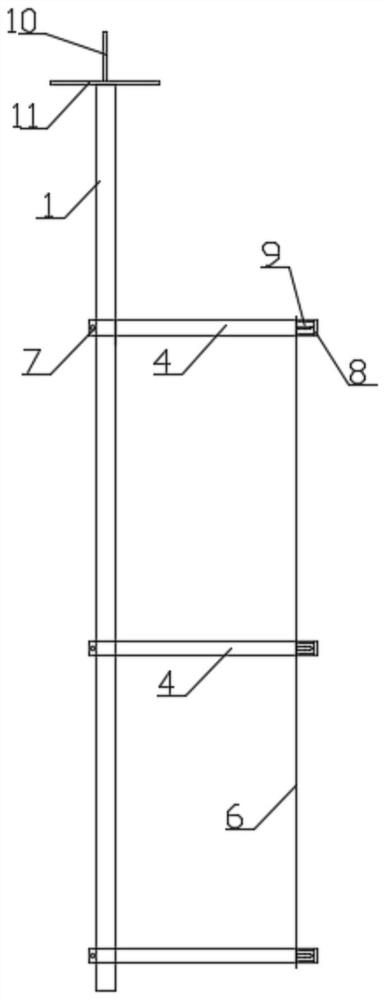

[0037] Such as Figure 1-Figure 5 Shown, the net clothing hydrodynamic test device of the present embodiment comprises flat plate 11, and the top surface of flat plate 11 is equipped with a plurality of spaced measuring devices 10, and the bottom surface of flat plate 11 is equipped with main frame 1,

[0038] The structure of the main frame 1 is as follows: it includes two cross bars 13 and two vertical bars 12 to form a quadrilateral structure, the top cross bar 13 is fixed to the bottom surface of the flat plate 11, and a cross strut 2 is installed between the two vertical bars 12. One end of the cross strut 2 and the junction of the cross bar 13 and the vertical bar 12 are installed with a diagonal strut 3;

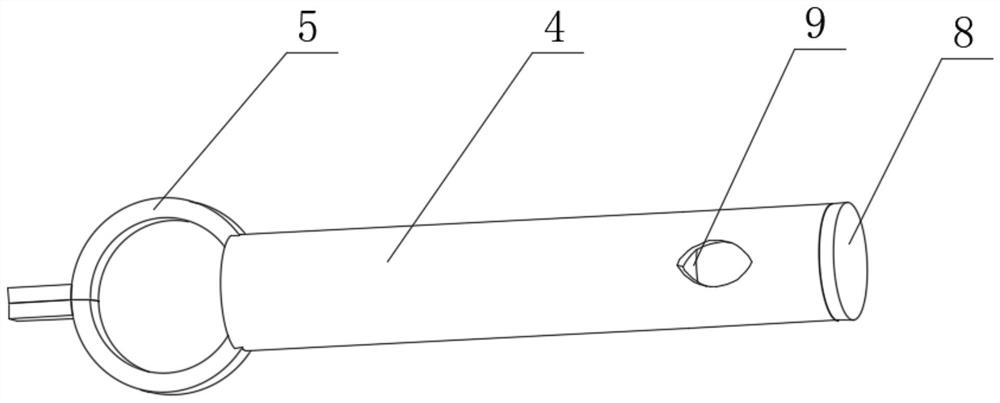

[0039] The vertical bar 12 is successively installed with a plurality of poles 4 at intervals from top to bottom, and one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com