Progesterone suppository processing and forming device

A technology for processing and molding ketone suppositories, which is applied in the field of processing and molding equipment for progesterone suppositories, can solve problems such as unfavorable continuous production of suppositories, adverse effects on users, and long-time stirring, so as to reduce delamination and chromatography, Reduce the melting time limit and smooth the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The content of the present invention will be further described below in conjunction with the accompanying drawings of the description. Obviously, the described embodiments are only a part of the embodiments of the present invention, not all of them.

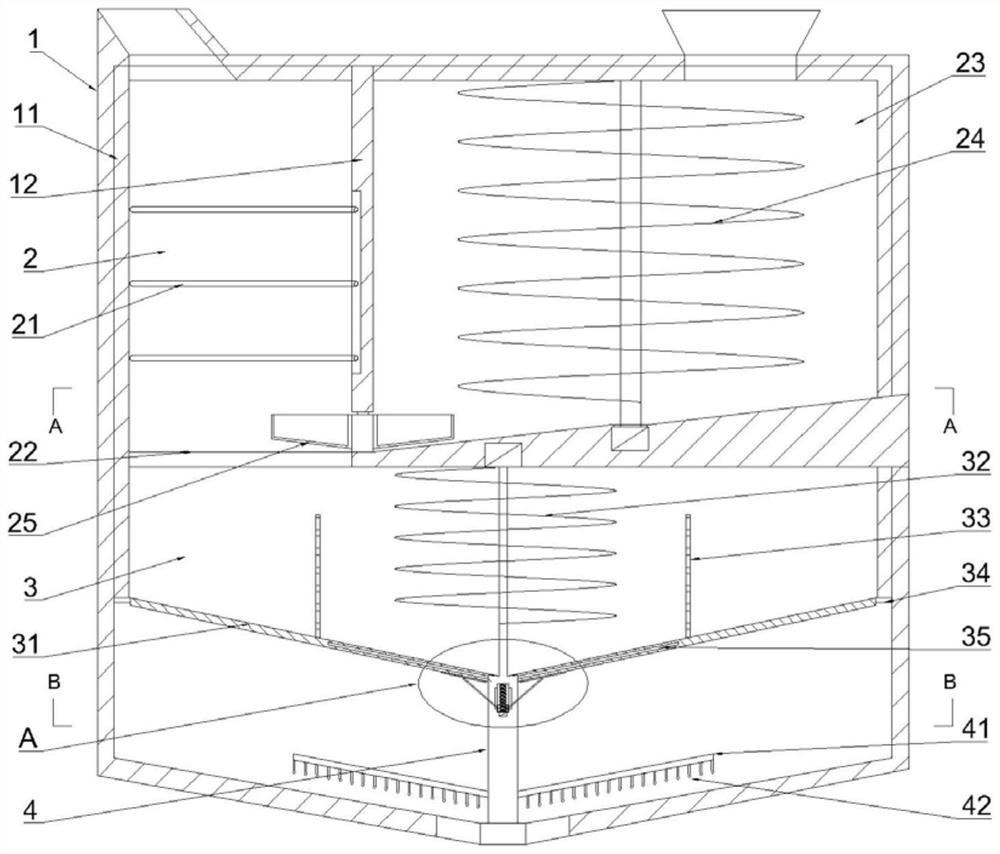

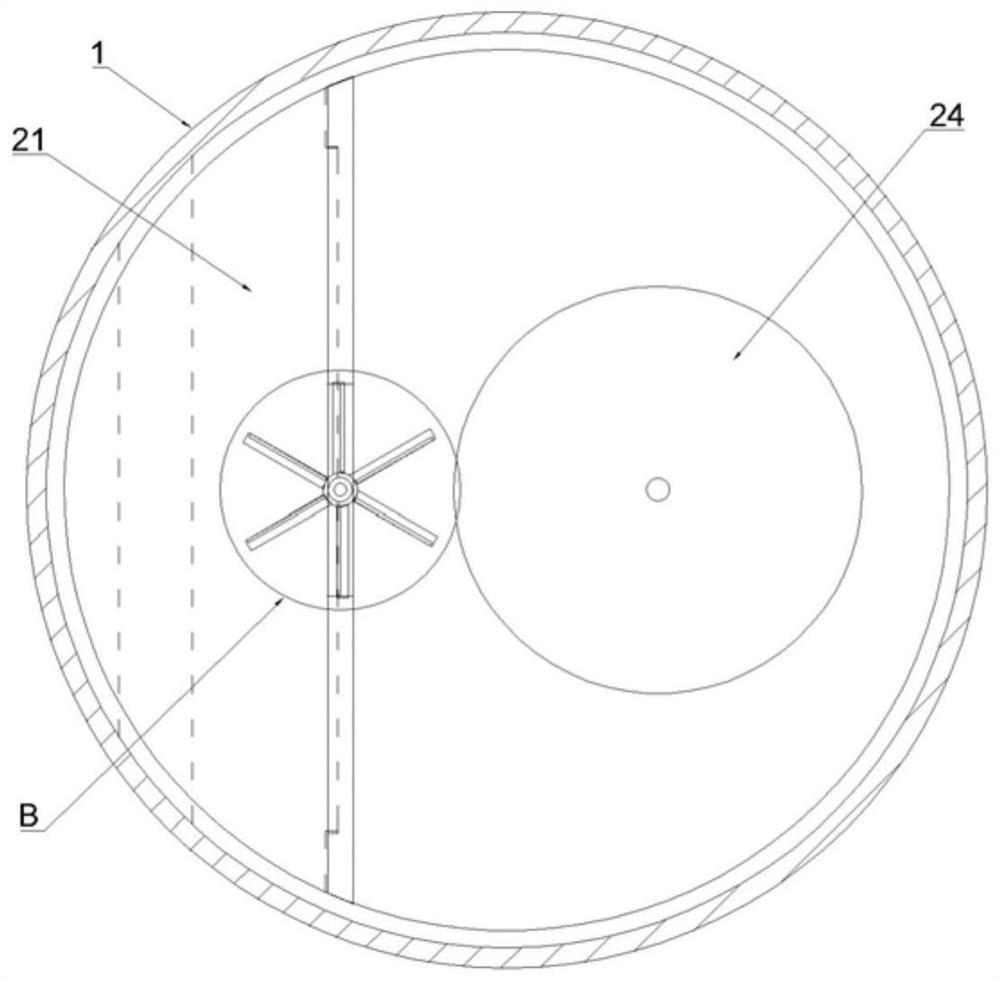

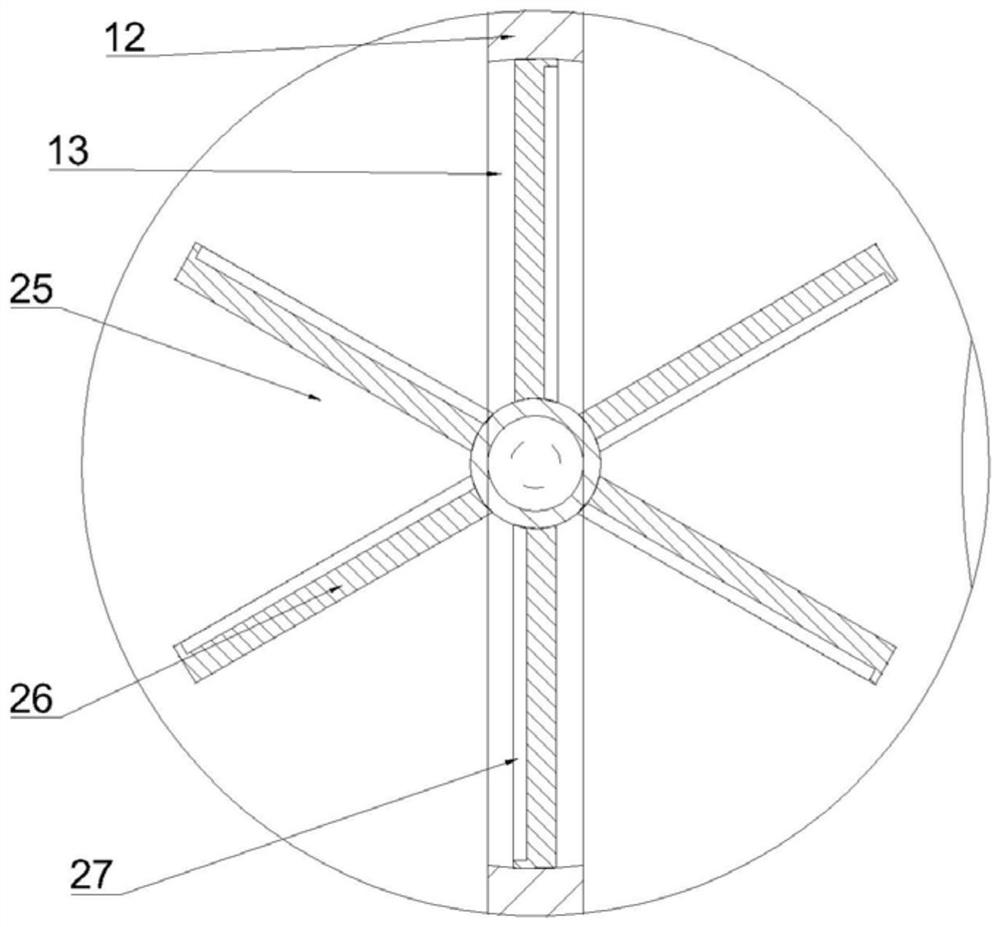

[0038] like Figure 1-5 As shown, the present embodiment provides a processing and molding device for progesterone suppositories, comprising a housing 1 and an inverted T-shaped partition 12 located in the inner cavity of the housing 1, the partition 12 divides the inner cavity of the housing 1 Separated into a progesterone chamber 2, a matrix chamber 23 on one side of the progesterone chamber 2, and a mixing chamber 3 below;

[0039] The housing 1 above the progesterone chamber 2 and the matrix chamber 23 is respectively provided with a feeding port. The shell 1 at the bottom of the mixing chamber 3 is provided with a discharge port communicating with an external filling machine;

[0040] The lower end of the partition ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap