Mounting buckle structure with shared hole and clamped connection of cavity sound insulation rubber blocks

A buckle structure and card installation technology, applied in the field of auto parts, to achieve the effect of simple process, low cost, product performance and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

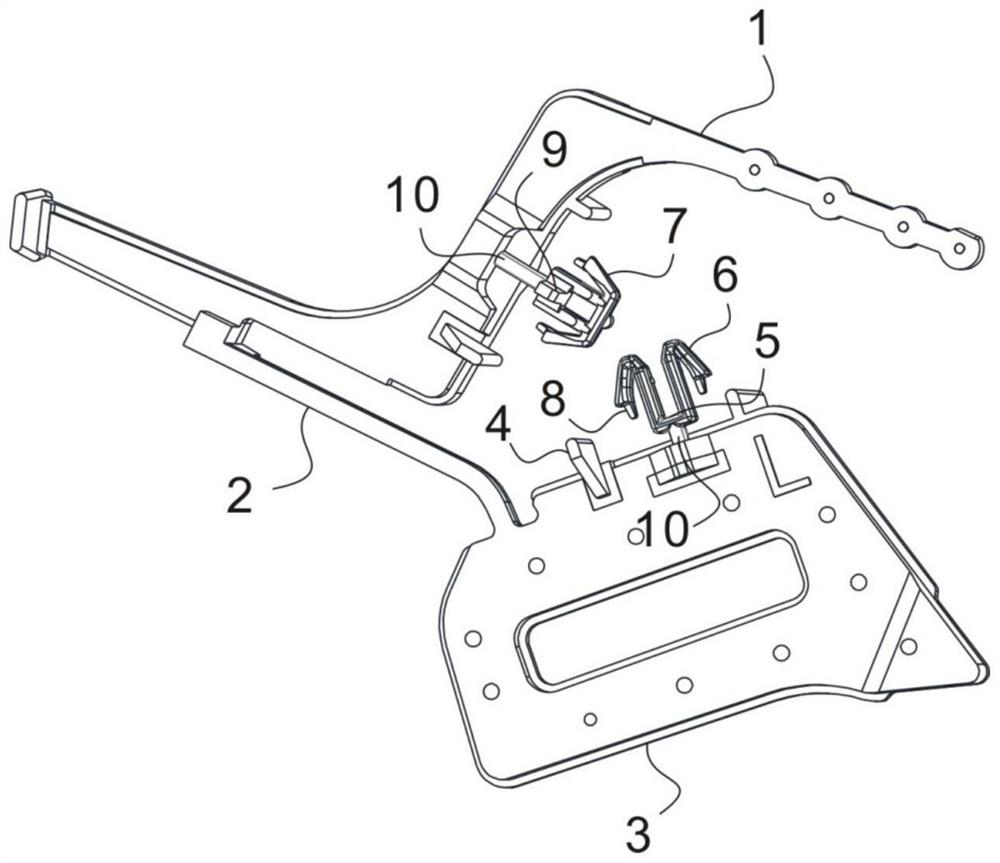

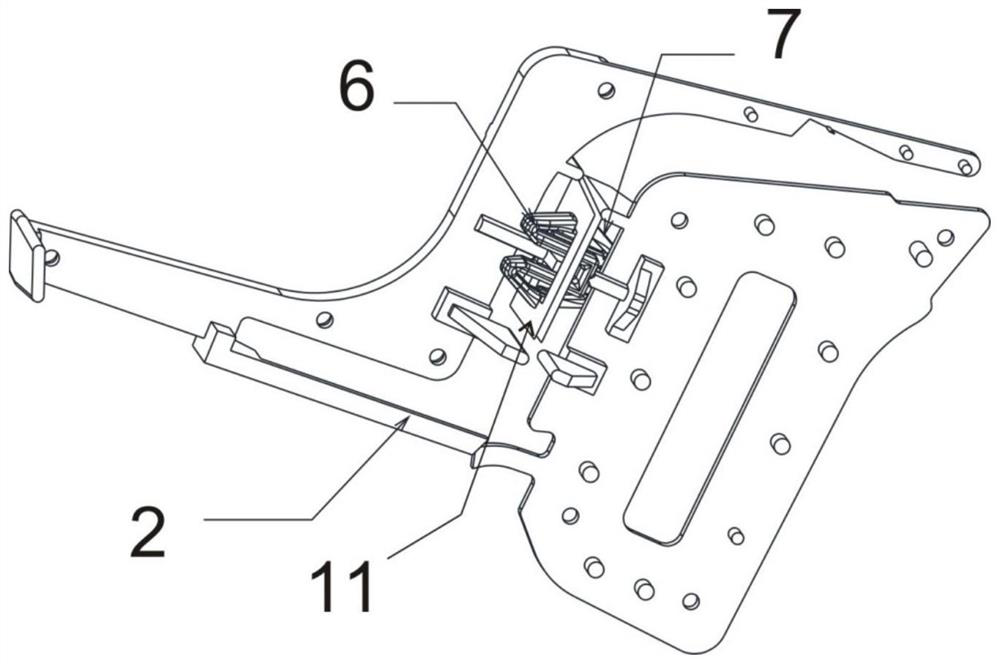

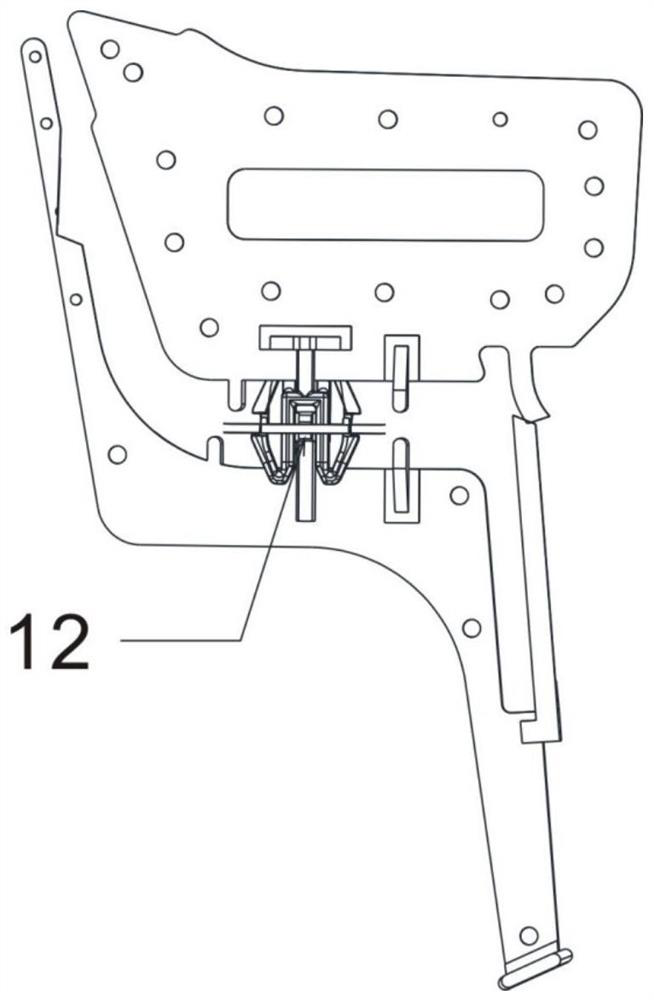

[0015] As shown in the figure, the present invention includes a first sound-insulating rubber block 1, a second sound-insulating rubber block 3 connected to the first sound-insulating rubber block 1 through an elastic bracket 2, and an installation buckle structure. The first sound-insulating rubber block 1 and the second sound-insulating rubber block 3 are provided with matching clips 4 in the Z direction. A buckle 6 and a second buckle 7 formed by merging two buckle units, the ends of the hook plates on both sides of the first buckle 6 and the second buckle 7 are provided with buckles The elastic piece 8, the abutting part of the buckle unit of the second buckle 7 is provided with an insertion protrusion 9, and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com