Special machine application system based on industrial internet platform

An industrial Internet and application system technology, applied in the field of special plane application system, can solve the problems of low efficiency of cargo transshipment and stacking, and achieve the effect of improving automation performance, improving continuity, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

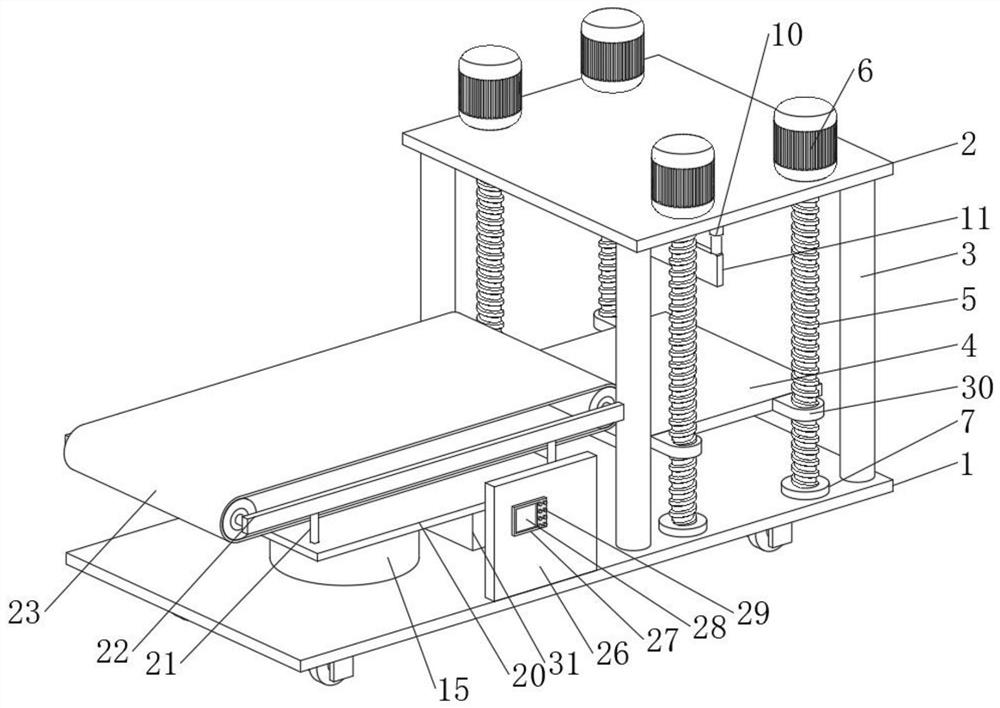

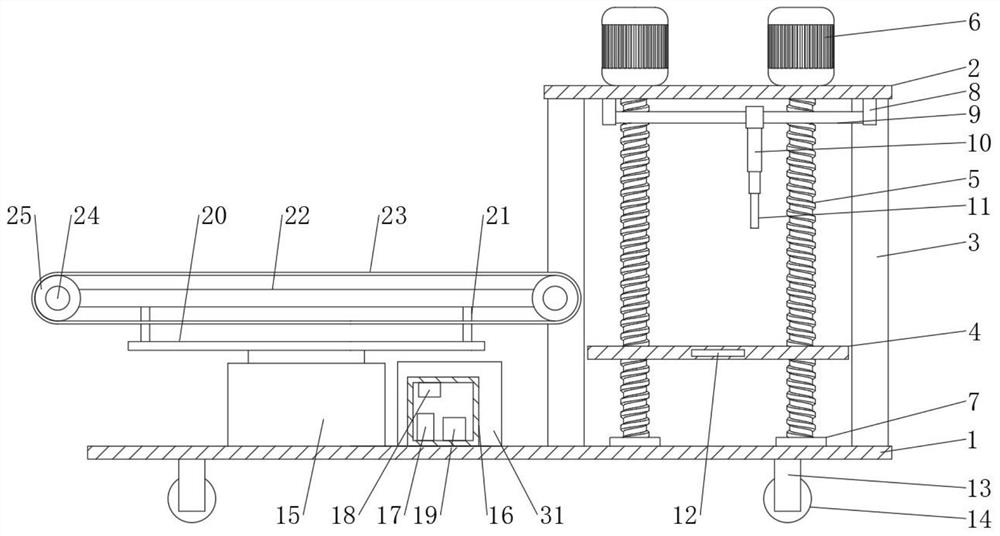

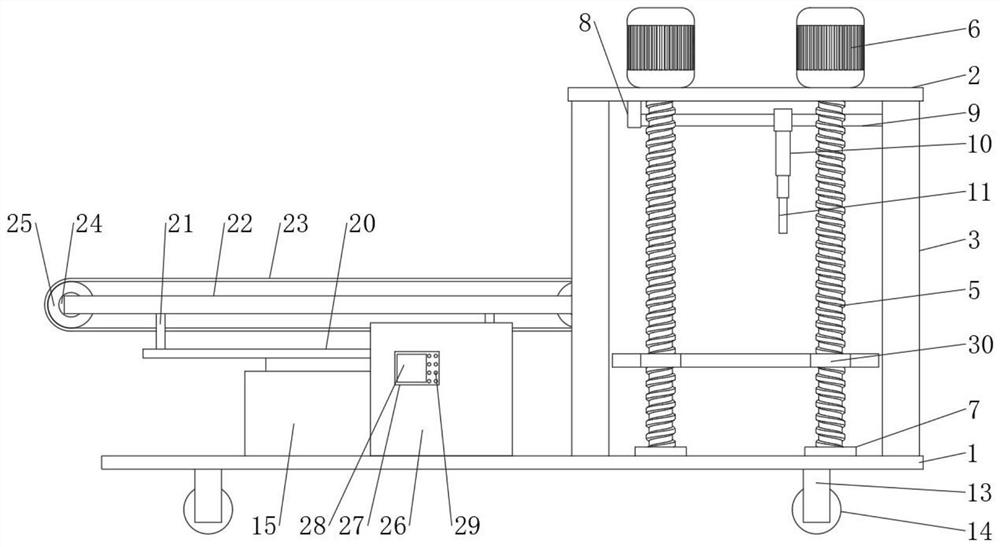

[0033] Such as Figure 1-4 As shown, the embodiment of the present invention provides a special machine application system based on the industrial Internet platform, including a base plate 1, the upper surface of the base plate 1 is fixedly connected with a pillar 3, and the upper surface of the pillar 3 away from the base plate 1 is fixedly connected with a top plate 2, and the bottom plate 1 Above and below the top plate 2, a platform 4 is provided. The front surface and the rear surface of the platform 4 are fixedly connected with ear pieces 30, and the upper surface of the ear piece 30 is provided with a threaded hole 32. The inside of the platform 4 is fixedly connected with a weighing The sensor 12, the upper surface of the top plate 2 is fixedly connected with the servo motor 6, the output end of the servo motor 6 runs through the top plate 2 and is fixedly connected with the screw mandrel 5, and the output end of the screw mandrel 5 away from the servo motor 6 passes th...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the length of the mounting part 8 can be adjusted, and the height of the rodless cylinder 9 can be lowered according to the needs of actual use, which can facilitate the transfer of some small-volume goods, which is beneficial The scope of application of the equipment is expanded to make the equipment more flexible and practical.

Embodiment 3

[0043] The difference between this embodiment and the second embodiment is that the rodless cylinder 9 can be replaced with a ball screw, which can further improve the transmission efficiency, and can also be applied to transshipment of goods with greater mass, thereby improving the transshipment efficiency of the goods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com