Building foundation pit slope protection system and method

A protection system, foundation pit edge technology, applied in construction, excavation, infrastructure engineering, etc., can solve the problems of increasing slope collapse, low installation and adjustment efficiency of drainage system, poor flexibility of equipment mechanism, etc., to improve reliability and stability. performance, fast and comprehensive discharge operations, improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

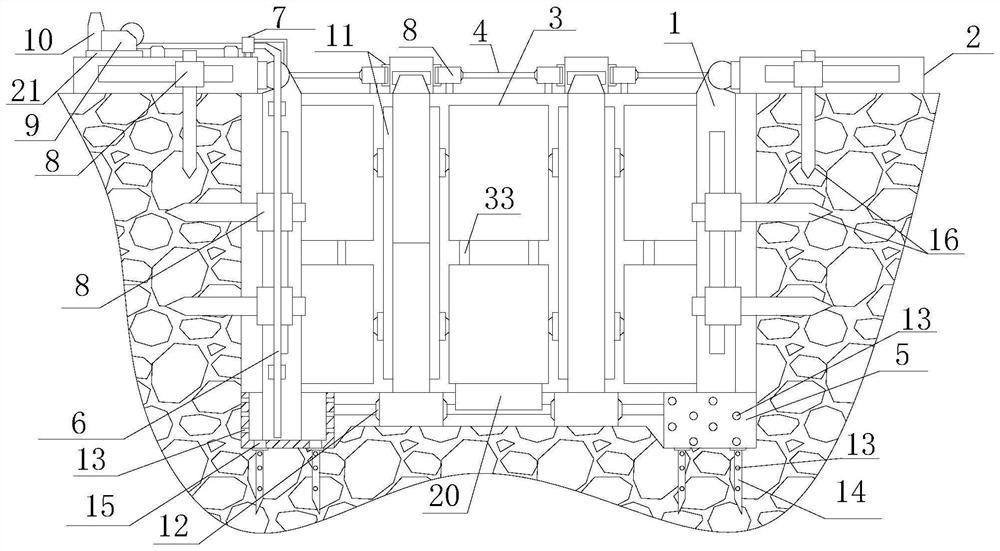

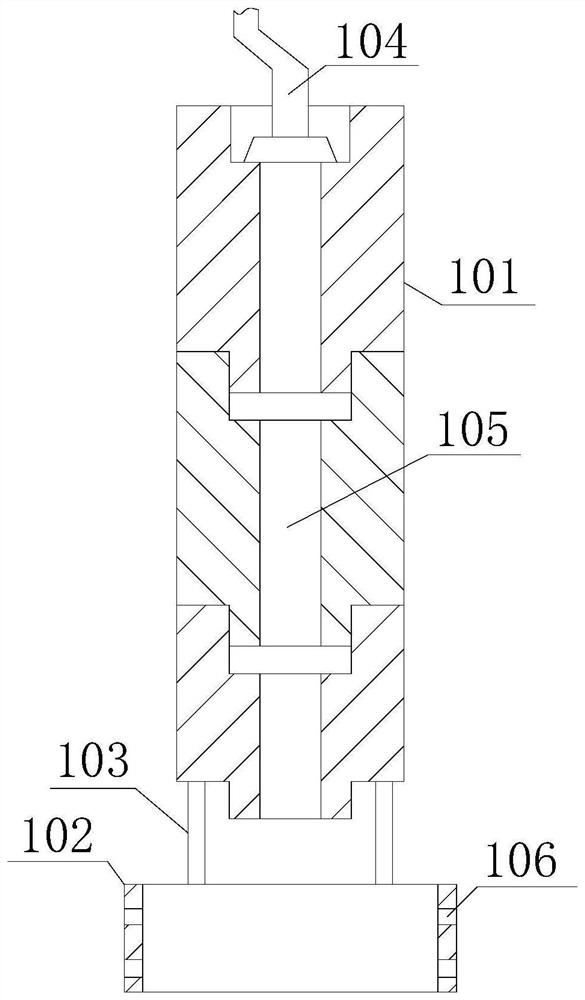

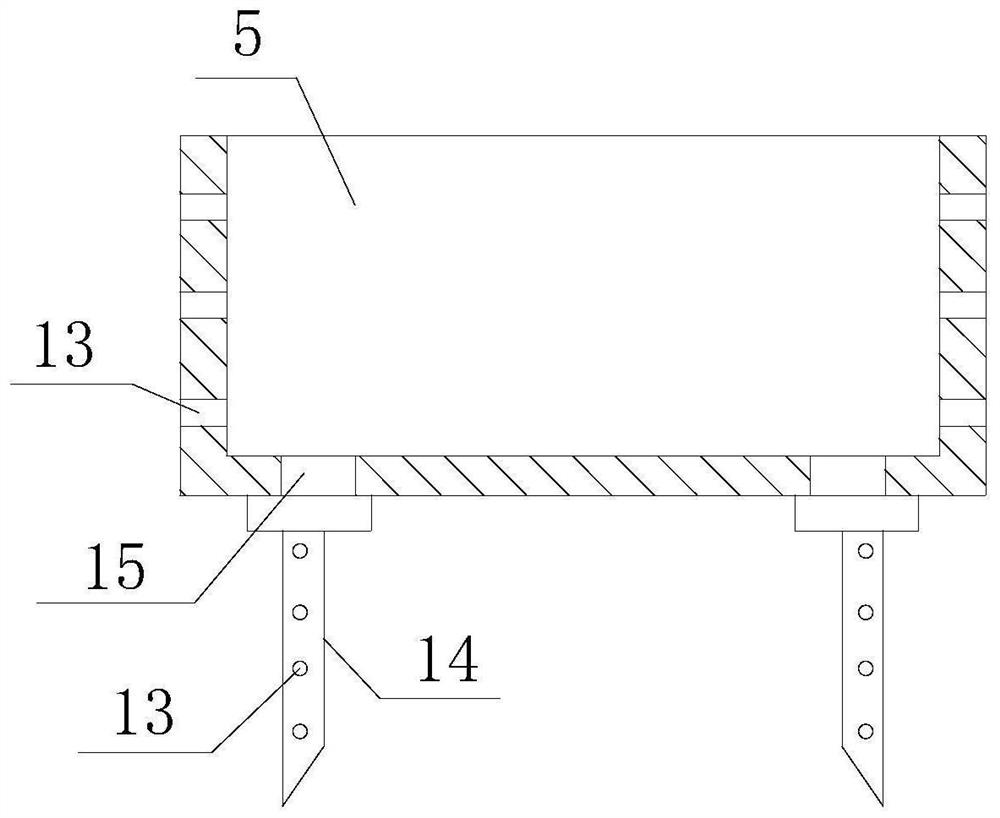

[0029] Such as figure 1 Shown in -5, a kind of building foundation pit side slope protection system, comprises protection column 1, positioning plate 2, protection screen plate 3, adjusting rod 4, water collection tray 5, diversion pipe 6, drainage pipe 7, slide block 8. The drainage pump 9 and the drive circuit 10, the positioning plate 2 and the side surface of the positioning plate 2 are all provided with a guide chute 11 parallel to the axes of the protective column 1 and the positioning plate 2, and at least two guide chute 11 are provided in the guide chute 11. The slider 8 is slidingly connected with the guide chute 11, the front end of the positioning plate 2 is hinged to the upper end of the protective column 1 through a hinge mechanism, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com