Granite plate dry-hanging structure and construction method thereof

A construction method and granite technology, applied in building construction, building material processing, covering/lining, etc., can solve problems such as offset, and achieve the effect of increasing stability and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is attached Figure 3-5 The application is described in further detail.

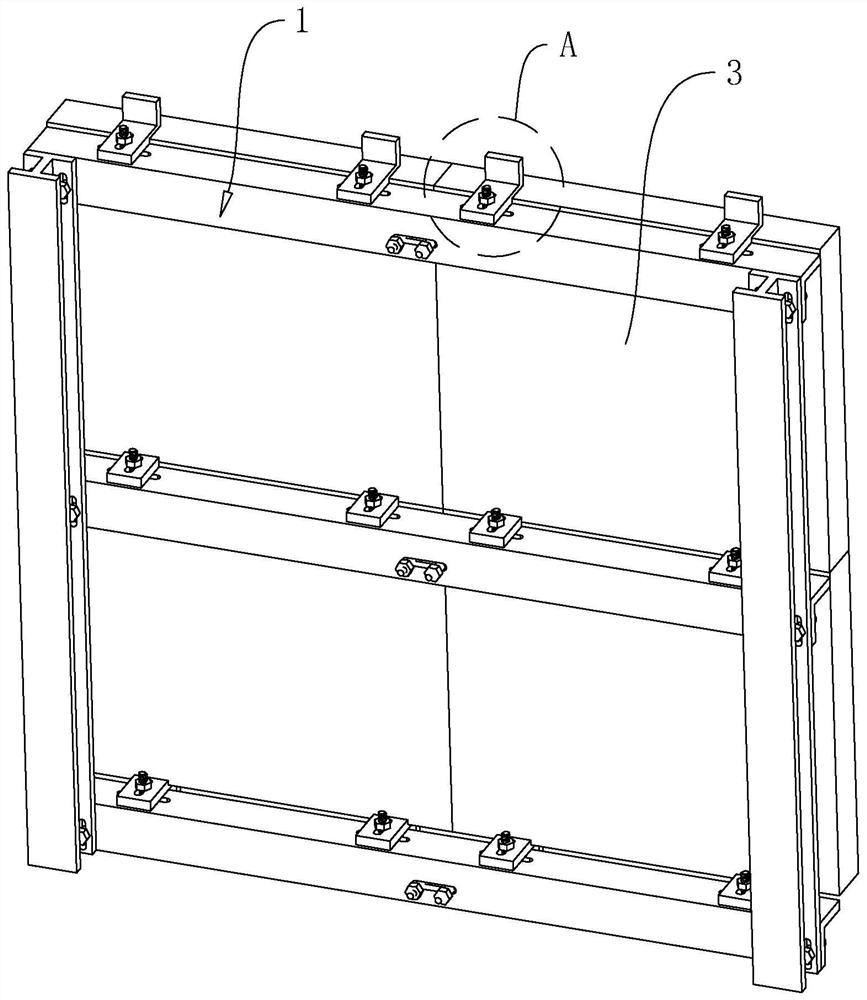

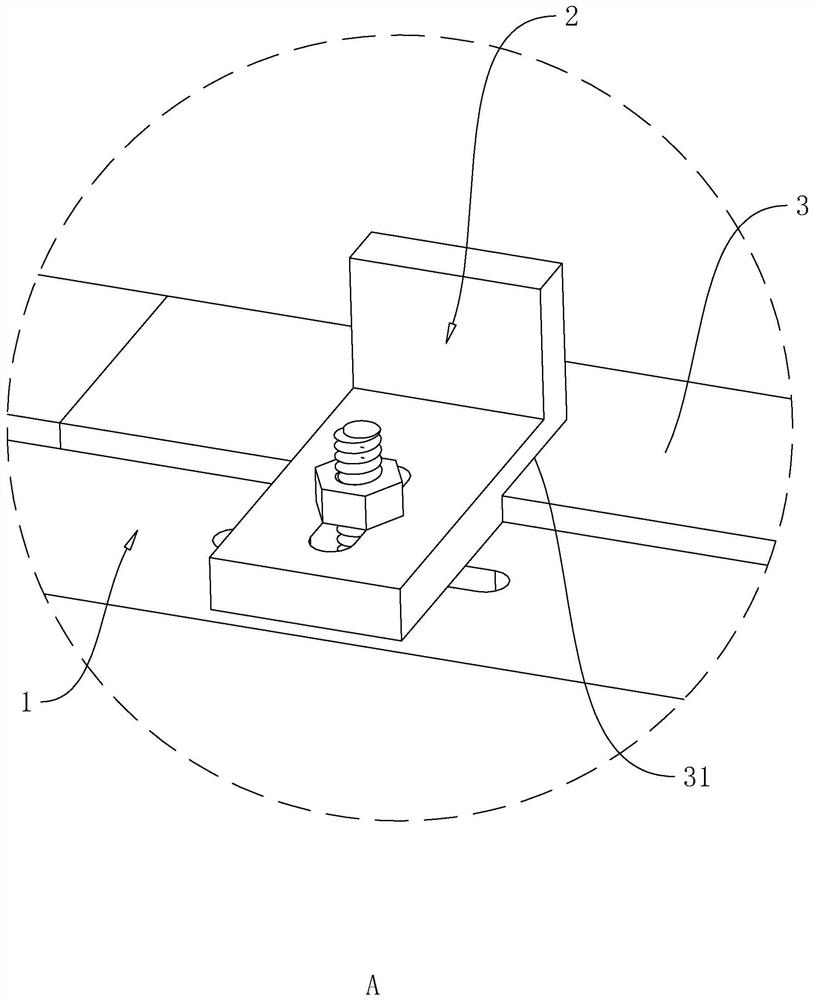

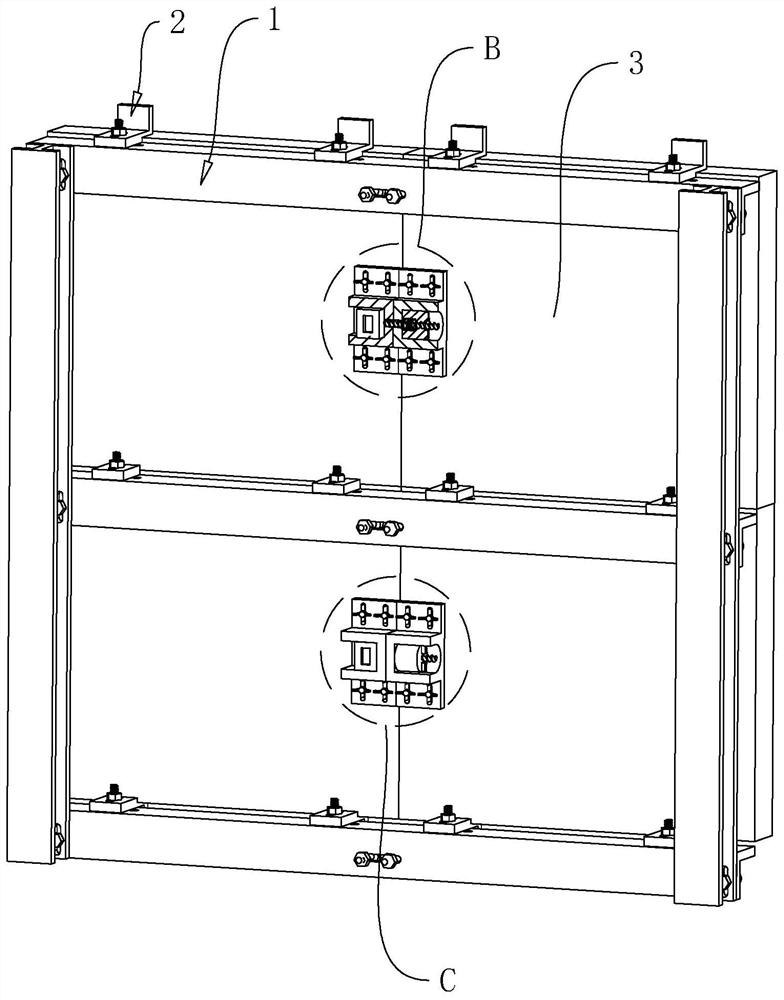

[0046] The embodiment of the present application discloses a structure for dry-hanging granite slabs. refer to image 3 The structure of the dry-hanging granite slab includes a keel frame 1, a T-shaped connector 2, a granite slab 3 and a fixing assembly, and the T-shaped connector 2 is used to fix two vertically adjacent granite slabs 3 on the keel frame 1, The fixing component is used for fixing two horizontally adjacent granite slabs 3 .

[0047] refer to image 3 and Figure 4 , the fixed assembly includes a first fixed block 4, a second fixed block 5, a sliding block 6, a screw 7 and a rotating block 8, the shapes of the first fixed block 4 and the second fixed block 5 are cuboids, and the first fixed block 4 The second fixing block 5 is respectively fixed on two horizontally adjacent granite slabs 3 , and the side wall of the first fixing block 4 abuts against the side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com