A shrinkage-resistant finishing method for wool fabrics with low strength loss

An anti-shrinkage finishing and fabric technology, which is applied in animal fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of strong fabric damage, etc., and achieve the effects of improved anti-felting performance, small application amount, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

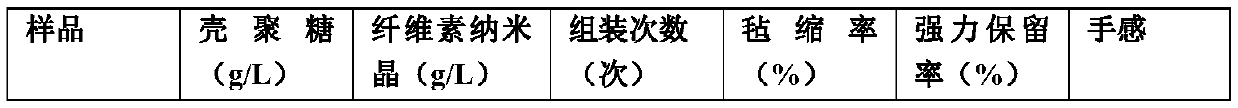

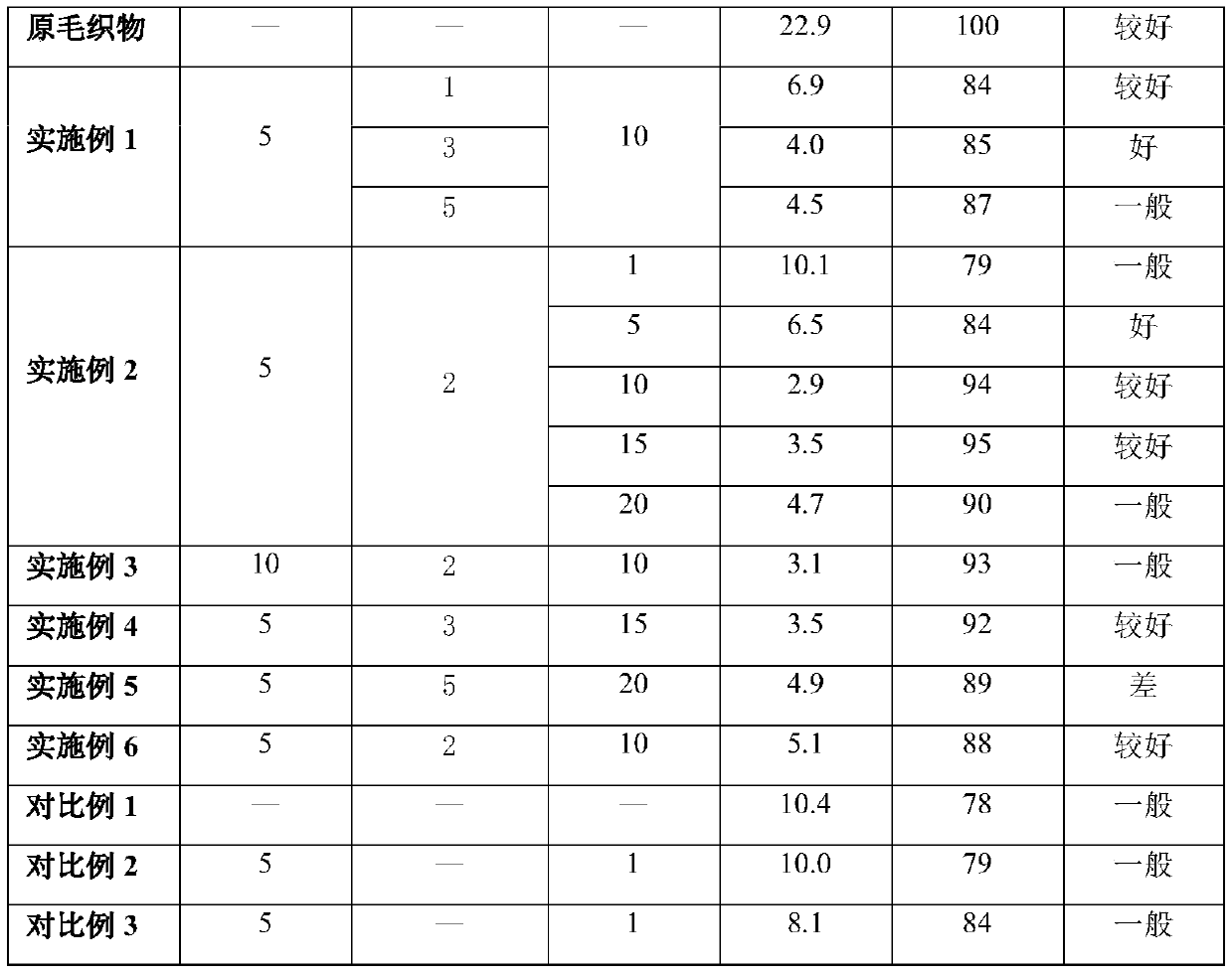

Examples

Embodiment 1

[0033] A low-strength and anti-shrinkage finishing method for wool fabrics, comprising the following steps:

[0034] (1) Put the wool fabric in a solution (pH 4) of 3wt% dichloroisocyanurate (DCCA), 1g / L penetrant JFC, and a bath ratio of 1:25 at room temperature for 30min at a bath ratio of 1:25, Then the fabric was mixed with 6wt% sodium bisulfite (NaHSO) at a bath ratio of 1:25 3 ) solution at 40°C for 20 minutes, and finally put the wool fabric in NaHCO with a pH of 8-9 3 solution, neutralize at 40°C for 20min.

[0035] (2) The woolen fabric treated in step (1) is first soaked in 5g / L chitosan finishing solution (bath ratio 1:50) for 5min, washed with water, and then soaked in 1g / L cellulose nanocrystal solution (bath ratio 1:50) ) for 5 minutes, washed with water, and then repeated the process of immersing in chitosan finishing solution and cellulose nanocrystal solution in turn, repeating the self-assembly procedure 10 times in total, and drying at 100°C for 10 minutes...

Embodiment 2

[0039] A low-strength and anti-shrinkage finishing method for wool fabrics, comprising the following steps:

[0040] (1) Put the woolen fabric in a solution (pH 4) of 3wt% dichloroisocyanurate (DCCA), 1g / L penetrant JFC, and a bath ratio of 1:25 for 30 minutes at room temperature, and then place the fabric in 6wt% Sodium bisulfite (NaHSO3 ) solution (bath ratio 1:25) at 40°C for 20 minutes, and finally put the wool fabric in NaHCO with a pH of 8-9 3 solution, neutralize at 40°C for 20min.

[0041] (2) The woolen fabric treated in step (1) is first soaked in 5g / L chitosan finishing solution (bath ratio 1:50) for 5min, washed with water, and then soaked in 2g / L cellulose nanocrystal solution (bath ratio 1:50) ) for 5 minutes, washed with water, and then repeated the process of immersing in the chitosan finishing solution and the cellulose nanocrystal solution in turn, repeating the self-assembly procedure 1, 5, 10, 15, 20 times in total, and drying at 100°C for 10 minutes .

...

Embodiment 3

[0044] A low-strength and anti-shrinkage finishing method for wool fabrics, comprising the following steps:

[0045] (1) Put the woolen fabric in a solution (pH 4) of 3wt% dichloroisocyanurate (DCCA), 1g / L penetrant JFC, and a bath ratio of 1:25 for 30 minutes at room temperature, and then place the fabric in 6wt% Sodium bisulfite (NaHSO 3 ) solution (bath ratio 1:25) at 40°C for 20 minutes, and finally put the wool fabric in NaHCO with a pH of 8-9 3 solution, neutralize at 40°C for 20min.

[0046] (2) The woolen fabric treated in step (1) is soaked in 10g / L chitosan finishing solution (bath ratio 1:50) for 5min, washed with water, and soaked in 2g / L cellulose nanocrystal solution (bath ratio 1:50) The self-assembly procedure was repeated 10 times in total, and then dried at 100°C for 10 minutes.

[0047] The felt shrinkage and tensile breaking strength of the finished fabric were tested according to the washing standard of Wool Bureau TM31 wool textile products and the sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com