A kind of wool anti-felt shrinkage finishing agent and preparation method and application thereof

A wool anti-felting and anti-shrinkage technology, which is applied in fiber treatment, textiles, papermaking, animal fibers, etc., can solve the problems of poor durability, high cost, fiber damage, etc., achieve mild process conditions and reduce felting shrinkage The effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A finishing method for making wool fabrics have an anti-felting function, the specific steps are as follows:

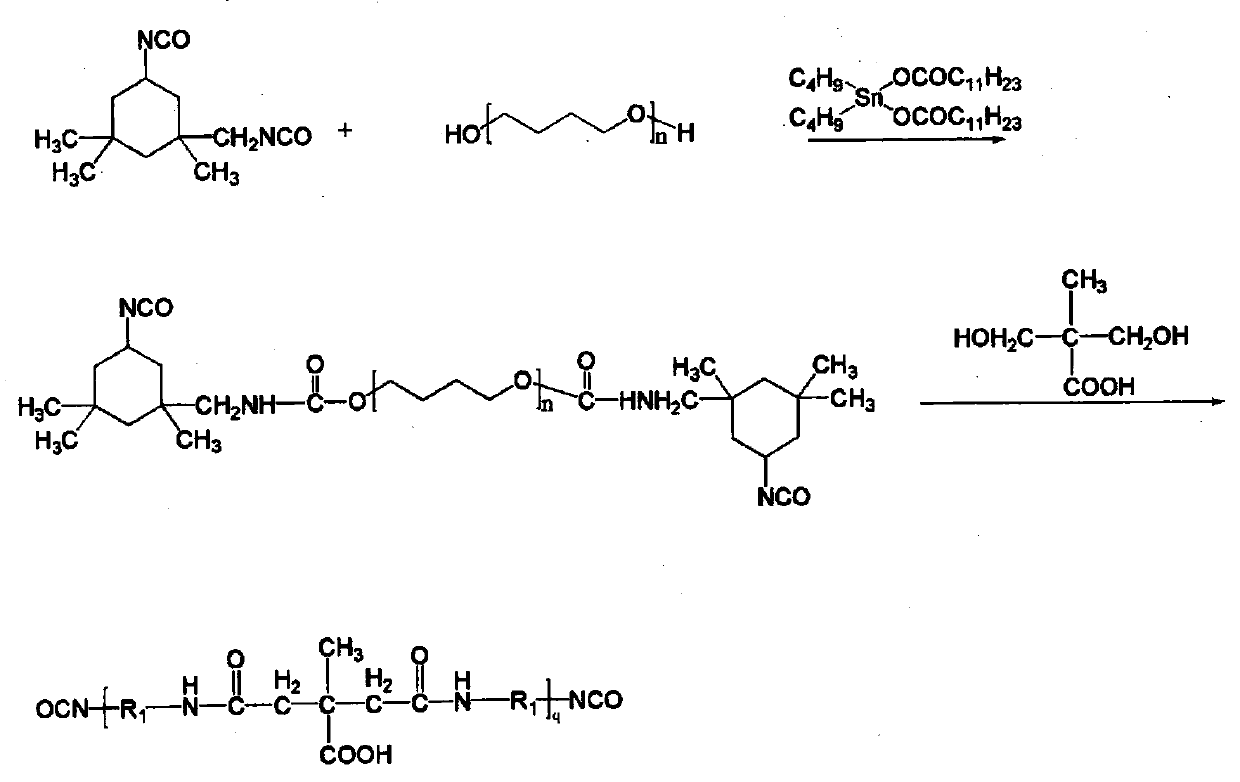

[0026] (1) Synthesis of polyurethane prepolymer

[0027] a. Dry polytetramethylene glycol, 2,2-(bis)methylol, and molecular sieves in a vacuum oven at 60°C for 12 hours;

[0028] b. In a 250mL three-necked bottle, add 4.8769g of isophorone diisocyanate, 10g of polytetramethylene glycol, and then add dibutyltin dilaurate in an amount of 0.1wt% of polytetramethylene glycol, at 85°C Oil bath reaction 3.5h;

[0029] c. After the above reaction is completed, lower the temperature of the oil bath to 70°C, add 0.8116g of 2,2-(bis)methylolpropionic acid to the reaction system, and continue the reaction for 3h;

[0030] d. After the above reaction is completed, add 10 mL of butanone treated with molecular sieves to the reaction system.

[0031] (2) Pretreatment of wool fabric

[0032] e. Take 12×16cm wool fabric;

[0033] f. Ultrasonic cleaning of the woolen fabric...

Embodiment 2

[0039] A finishing method for making wool fabrics have an anti-felting function, the specific steps are as follows:

[0040] (1) Synthesis of polyurethane prepolymer

[0041] a. Dry polytetramethylene glycol, 2,2-(bis)methylol, and molecular sieves in a vacuum oven at 60°C for 12 hours;

[0042] b. In a 250mL three-necked bottle, add 4.8769g of isophorone diisocyanate, 10g of polytetramethylene glycol, and then add dibutyltin dilaurate, the amount of which is 0.1wt% of the amount of polytetramethylene glycol. Bath reaction 3.5h;

[0043] c. After the above reaction is completed, lower the temperature of the oil bath to 70°C, add 0.8116g of 2,2-(bis)methylolpropionic acid to the reaction system, and continue the reaction for 3h;

[0044] d. After the above reaction is completed, add 10 mL of butanone treated with molecular sieves to the reaction system.

[0045] (2) Pretreatment of wool fabric

[0046] e. Take 12×16cm wool fabric;

[0047] f. Ultrasonic cleaning of the woole...

Embodiment 3

[0053] A finishing method for making wool fabrics have an anti-felting function, the specific steps are as follows:

[0054] (1) Synthesis of polyurethane prepolymer

[0055] a. Dry polytetramethylene glycol, 2,2-(bis)methylol, and molecular sieves in a vacuum oven at 60°C for 12 hours;

[0056] b. In a 250mL three-necked bottle, add 4.8769g of isophorone diisocyanate, 10g of polytetramethylene glycol, and then add dibutyltin dilaurate, the amount of which is 0.1wt% of the amount of polytetramethylene glycol. Bath reaction 3.5h;

[0057] c. After the above reaction is completed, lower the temperature of the oil bath to 70°C, add 0.8116g of 2,2-(bis)methylolpropionic acid to the reaction system, and continue the reaction for 3h;

[0058] d. After the above reaction is completed, add 10 mL of butanone treated with molecular sieves to the reaction system.

[0059] (2) Pretreatment of wool fabric

[0060] e. Take 12×16cm wool fabric;

[0061] f. Ultrasonic cleaning of the woo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com