Conductive polyethylene material based on nano modification and preparation method thereof

A nano-modification, polyethylene technology, applied in the field of polyethylene materials, can solve the problems of complex processing technology and the electrical conductivity of conductive polyethylene materials cannot meet the actual needs, and achieve the effect of improving the electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

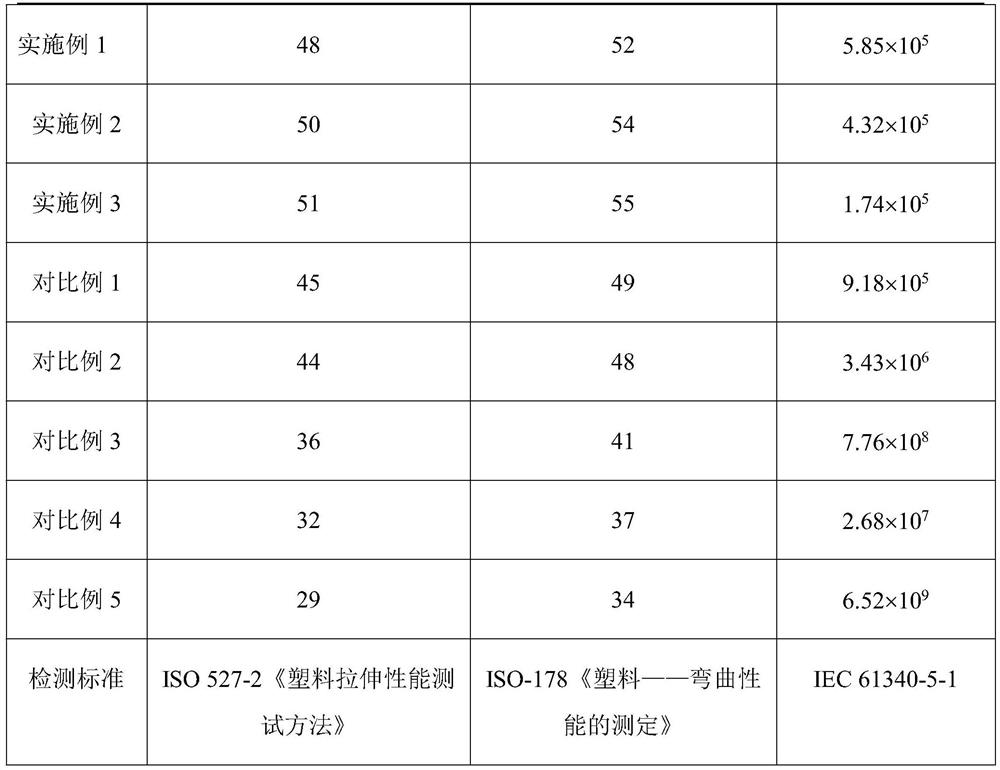

Embodiment 1

[0038] A preparation method based on nano-modified conductive polyethylene material, comprising the following steps:

[0039] Step 1: Take the glass fiber, clean it and dry it in vacuum for 20 hours, and then put it in the plasma equipment for plasma pretreatment. The treatment conditions are: vacuum degree 18Pa, power 100W, treatment time 85s, and the working gas is oxygen respectively;

[0040] Step 2: Take the glass fiber treated in step 1, place it in a sputtering chamber, use pure copper and pure silver as sputtering targets, maintain a vacuum degree of 1.0Pa in an argon environment, sputter the surface of the glass fiber and cover forming an alloy layer; the deposition rate of the pure silver target is 1.10nm / s, and the deposition rate of the pure copper target is 0.015nm / s; the glass fiber is rotated during the sputtering process to ensure that the glass fiber surface is evenly coated There is an alloy layer.

[0041] Step 3: Take flake graphite, sodium nitrate and conce...

Embodiment 2

[0049] A preparation method based on nano-modified conductive polyethylene material, comprising the following steps:

[0050] Step 1: Take the glass fiber, clean it and dry it in vacuum for 22 hours, and then put it in the plasma equipment for plasma pretreatment. The treatment conditions are: vacuum degree 19Pa, power 105W, treatment time 88s, and the working gas is oxygen respectively;

[0051] Step 2: Take the glass fiber treated in step 1, place it in a sputtering chamber, use pure copper and pure silver as sputtering targets, maintain a vacuum degree of 1.0Pa in an argon environment, sputter the surface of the glass fiber and cover forming an alloy layer; the deposition rate of the pure silver target is 1.13nm / s, and the deposition rate of the pure copper target is 0.018nm / s; the glass fiber is rotated during the sputtering process to ensure that the surface of the glass fiber is evenly coated There is an alloy layer.

[0052] Step 3: Take flake graphite, sodium nitrate ...

Embodiment 3

[0060] A preparation method based on nano-modified conductive polyethylene material, comprising the following steps:

[0061] Step 1: Take the glass fiber, clean it and dry it in vacuum for 24 hours, and then put it in the plasma equipment for plasma pretreatment. The treatment conditions are: vacuum degree 20Pa, power 110W, treatment time 90s, and the working gas is oxygen respectively;

[0062] Step 2: Take the glass fiber treated in step 1, place it in a sputtering chamber, use pure copper and pure silver as sputtering targets, maintain a vacuum degree of 1.0Pa in an argon environment, sputter the surface of the glass fiber and cover The deposition rate of the pure silver target material is 1.15nm / s, and the deposition rate of the pure copper target material is 0.020nm / s; the glass fiber is rotated during the sputtering process to ensure that the surface of the glass fiber is evenly coated There is an alloy layer.

[0063] Step 3: Take flake graphite, sodium nitrate and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com