Traction swing type dish-washing machine spraying mechanism

A dishwasher and swing-type technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., which can solve the problem of low spray water pressure, cleaning dead angle, time-consuming and water-consuming To avoid problems such as electricity consumption, to achieve the effect of avoiding movement resistance and facilitating water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

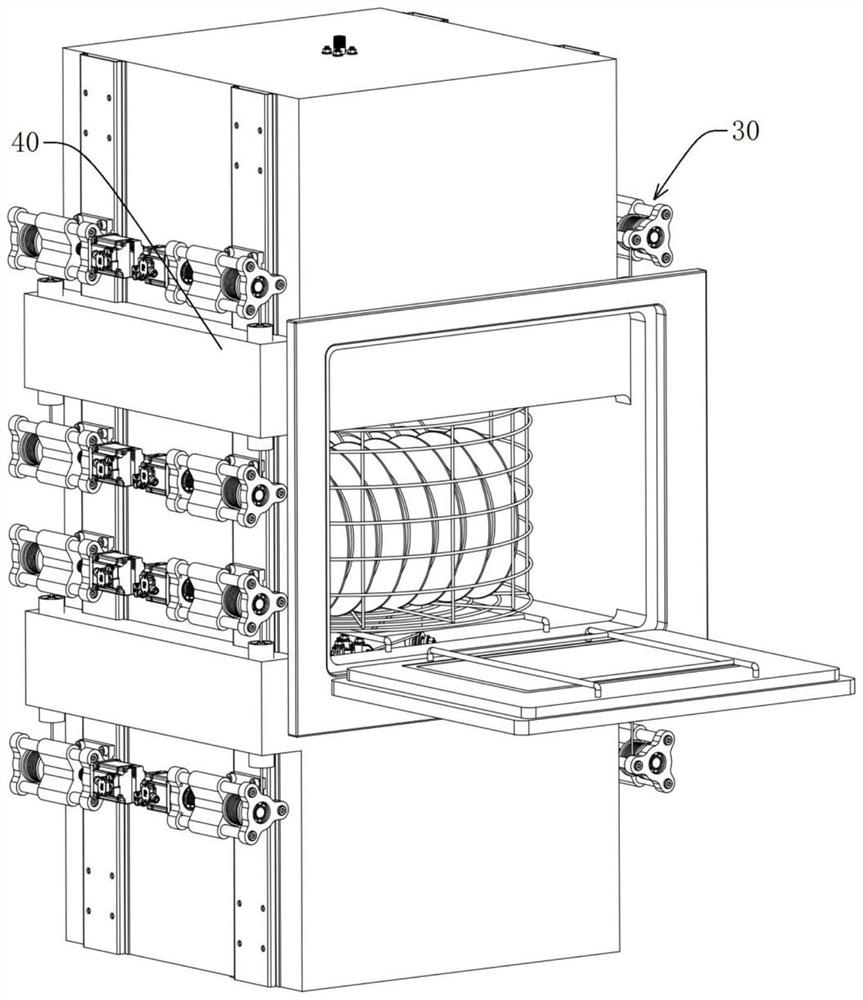

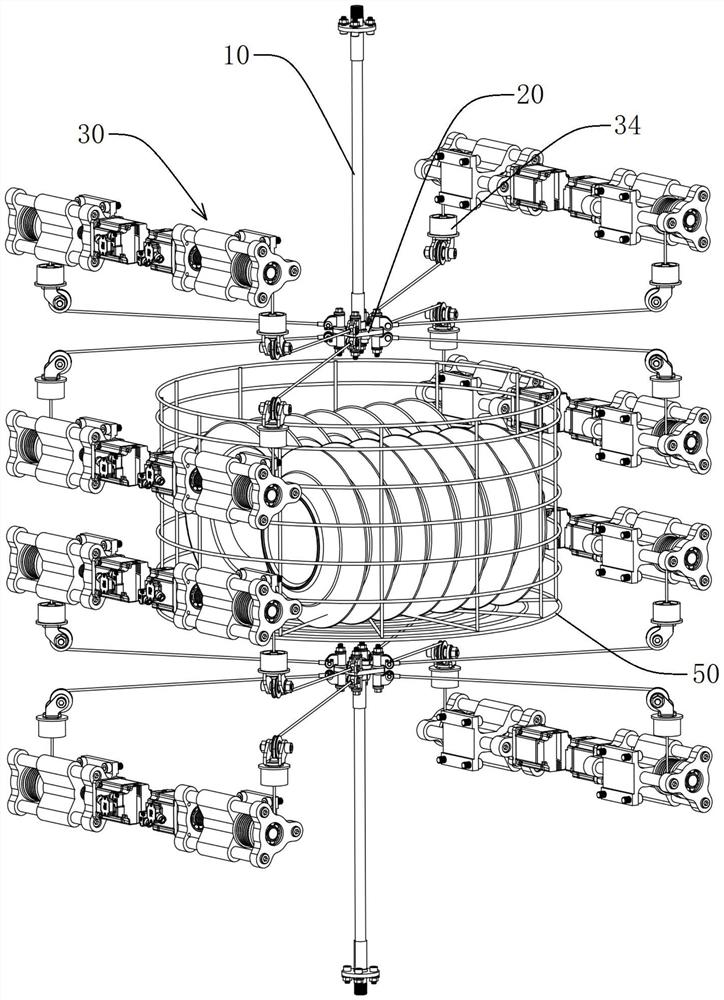

[0041] Such as figure 1 and figure 2 As shown, this embodiment relates to a pulling and swinging dishwasher spray mechanism, including: a swinging water guide pipe 10, a spray head assembly 20 and a pulling assembly 30;

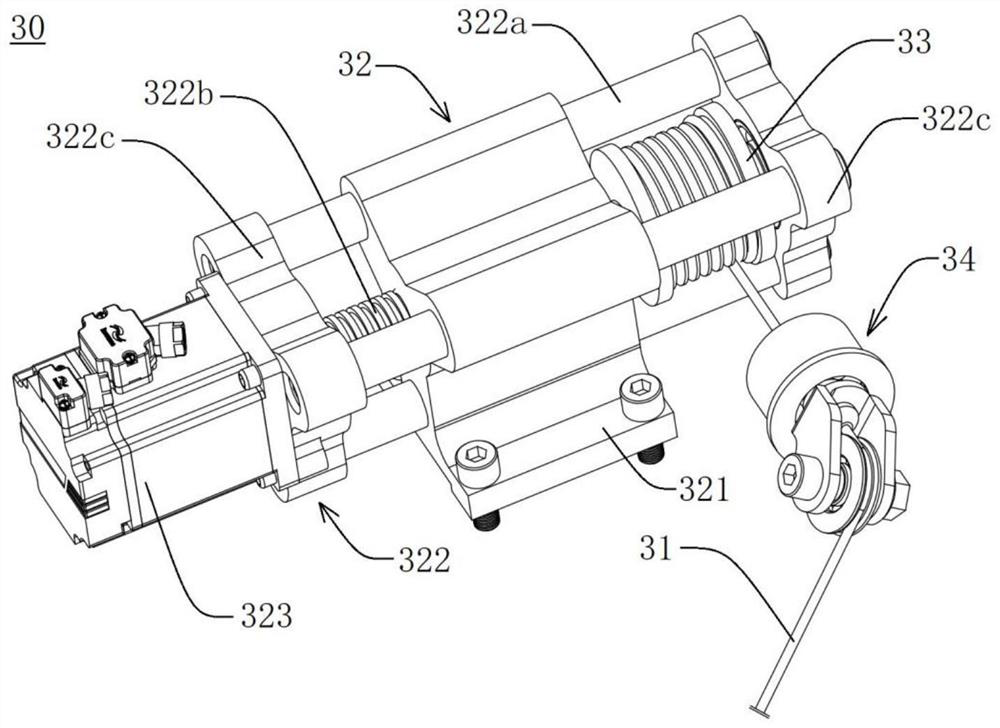

[0042] Such as figure 1 , figure 2 and Figure 9 As shown, the nozzle assembly 20 includes a nozzle 21 and a nozzle holder 22. The nozzle 21 is fixed on the nozzle holder 22. The nozzle holder 22 includes a water-guiding rod and a seat fixed at one end of the rod. The seat is preferably rectangular. One end of the oscillating water conduit 10 is fixedly connected to the water-guiding rod on the nozzle seat 22 , and the other end of the oscillating water conduit 10 is fixedly connected to the dishwasher housing 40 through a connector.

[0043] Such as figure 2 As shown, in this embodiment, a pulling and swinging dishwasher spray mechanism is arranged above and below the dishwasher basket 50; There are four groups on the upper and lower sides of each n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com