Dough mixing device

A technology of mixing bucket and support table, which is applied in the directions of mixing/kneading with horizontal installation tools and mixing/kneading with vertical installation tools, can solve the problems of uneven dough fermentation, uneven mixing of flour and yeast powder, etc. good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

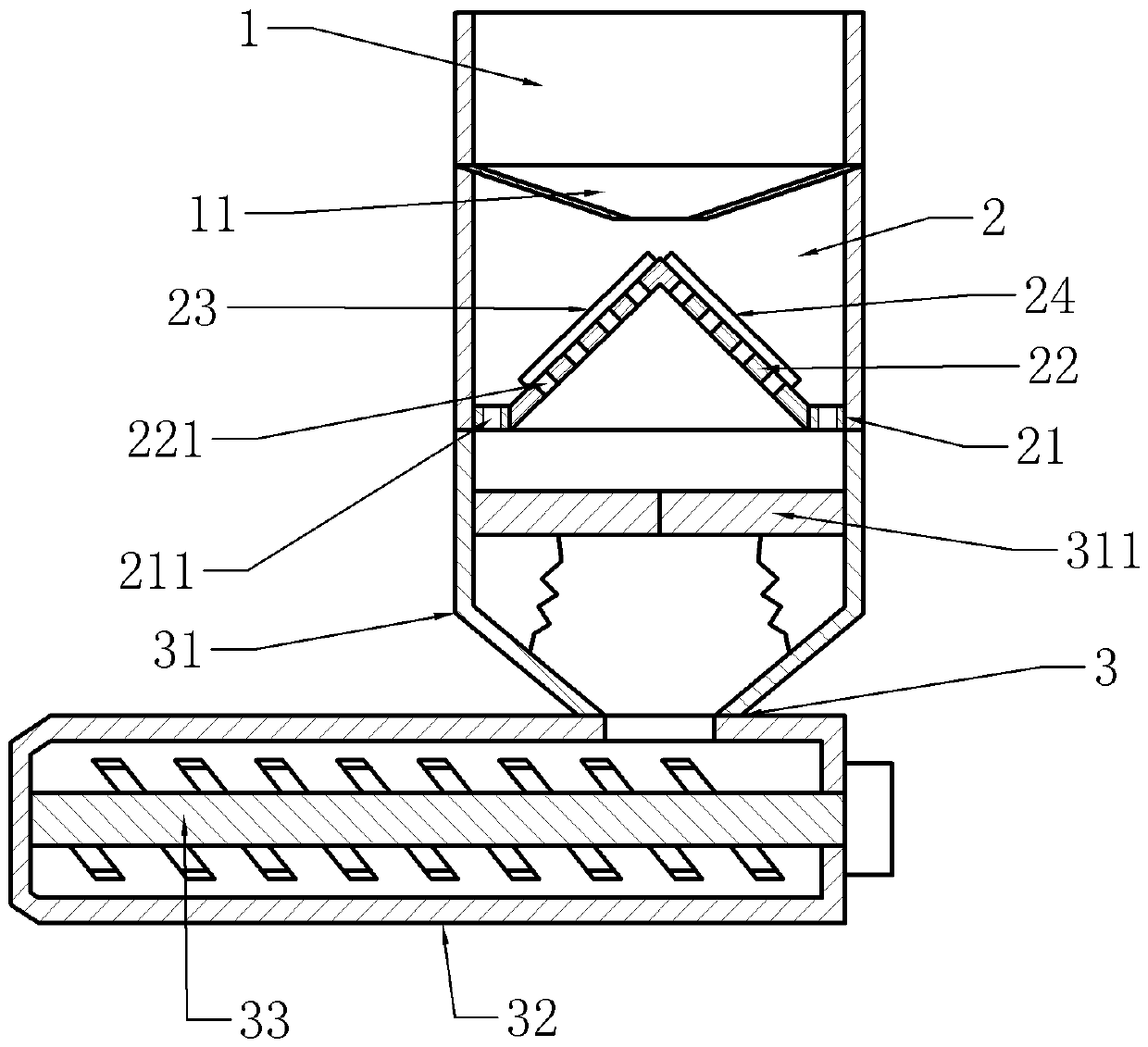

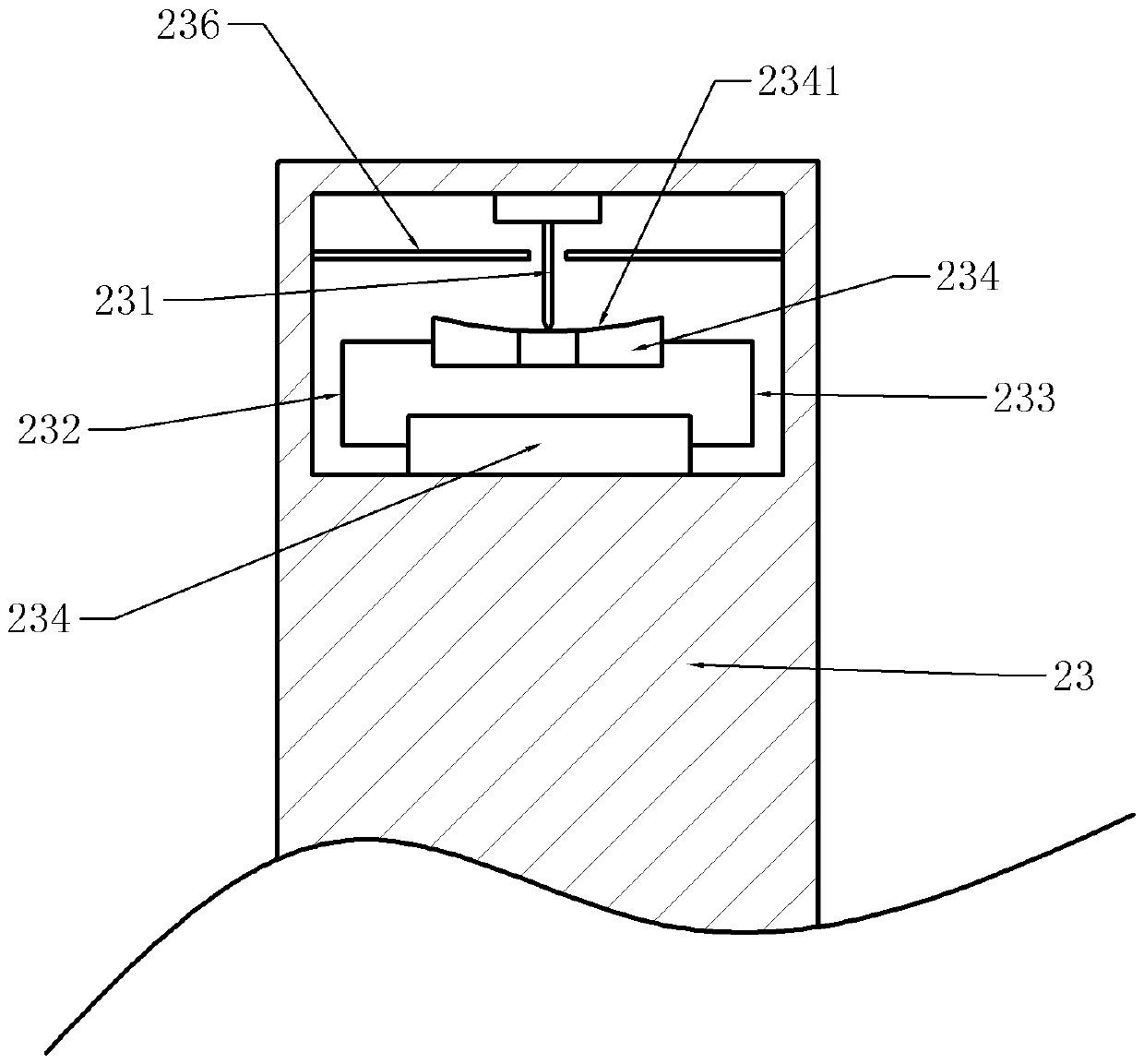

[0027] The reference numerals in the accompanying drawings of the description include: feeding barrel 1, material guiding barrel 11, material guiding port 111, mixing barrel 2, sealing ring 21, through hole 211, support platform 22, feeding port 221, first breaking up Rod 23, conductive needle 231, first conductive wire 232, second conductive wire 233, conductive sheet 234, chute 2341, electromagnet 235, trigger lever 236, second breaking rod 24, mixing bucket 3, vertical bucket 31, Baffle plate 311, horizontal bucket 32, stirring shaft 33.

[0028] Such as figure 1 As shown, a kneading device includes a feeding cylinder 1, a pre-mixing mechanism, a water pump and a stirring mechanism arranged sequentially from top to bottom; both ends of the feeding cylinder 1 are open, and the bottom of the feeding cylinder 1 is provided with a An inverted cone-shaped guide cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com