Damping device of shuttle tanker comfort superstructure and manufacturing method

A vibration damping device and comfort technology, which is applied in the field of structural vibration damping devices based on the comfort of shuttle tankers, can solve problems such as damage, affecting comfort, and affecting work efficiency, so as to reduce vibration force transmission and achieve significant vibration reduction effects. Simple and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

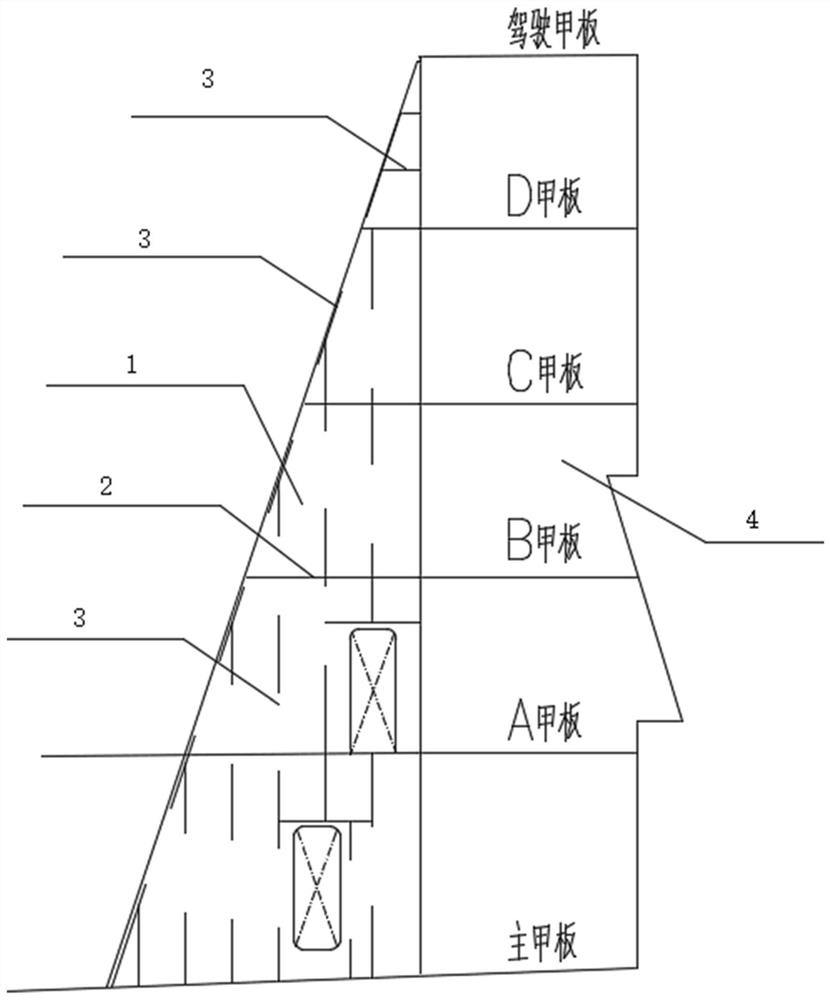

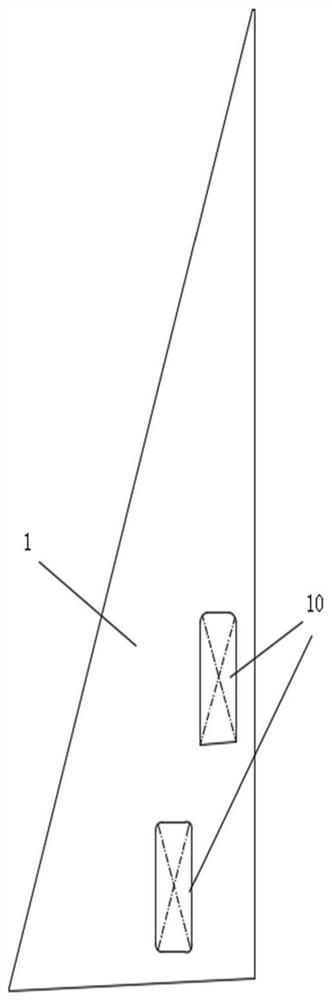

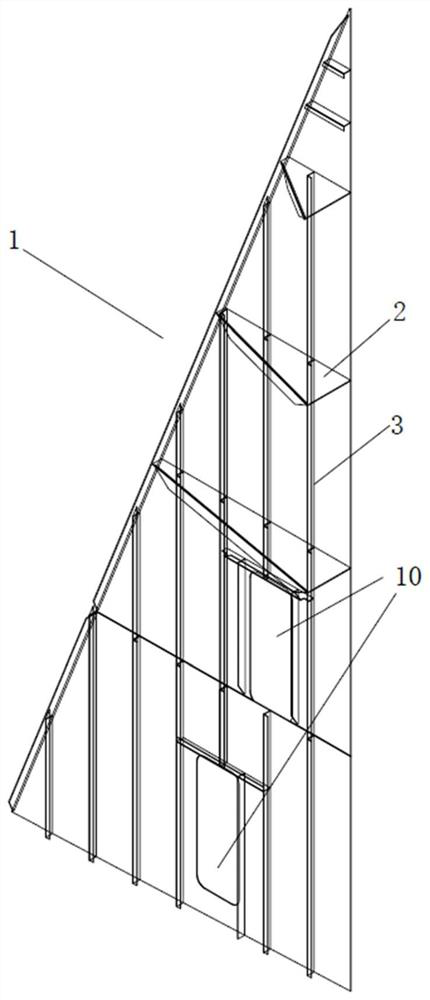

[0030] like Figure 1~6 As shown in the figure, a vibration damping device for the comfort superstructure of a shuttle tanker includes a transverse bracket 1, a horizontal beam 2 and a reinforcing rib 3, and the transverse bracket 1 is welded and fixed on the left and right sides of the front and rear bulkheads 4 of the superstructure. The side, the horizontal beam 2 and the stiffener 3 are welded and fixed on the transverse bracket plate frame 1 . The thickness of the transverse bracket-type grillage 1 is equal to the thickness of the wall plate built on the main hull, the thickness is generally 8-10mm, and the direction of the plate thickness is aligned with the wall plate of the bulkhead. The span between the structures is long, and the higher the height direction, the better, and the height is at least not less than two deck heights. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com