An assembled outer sleeve staggered flange intersecting joint and its construction method

A technology of outer sleeve and staggered method, applied in the direction of protective buildings/shelters, building types, buildings, etc., can solve the problems of poor detachable adjustment performance, difficult to guarantee welding quality, complicated construction process, etc. Good installation performance, good seismic performance, avoiding the effect of on-site welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

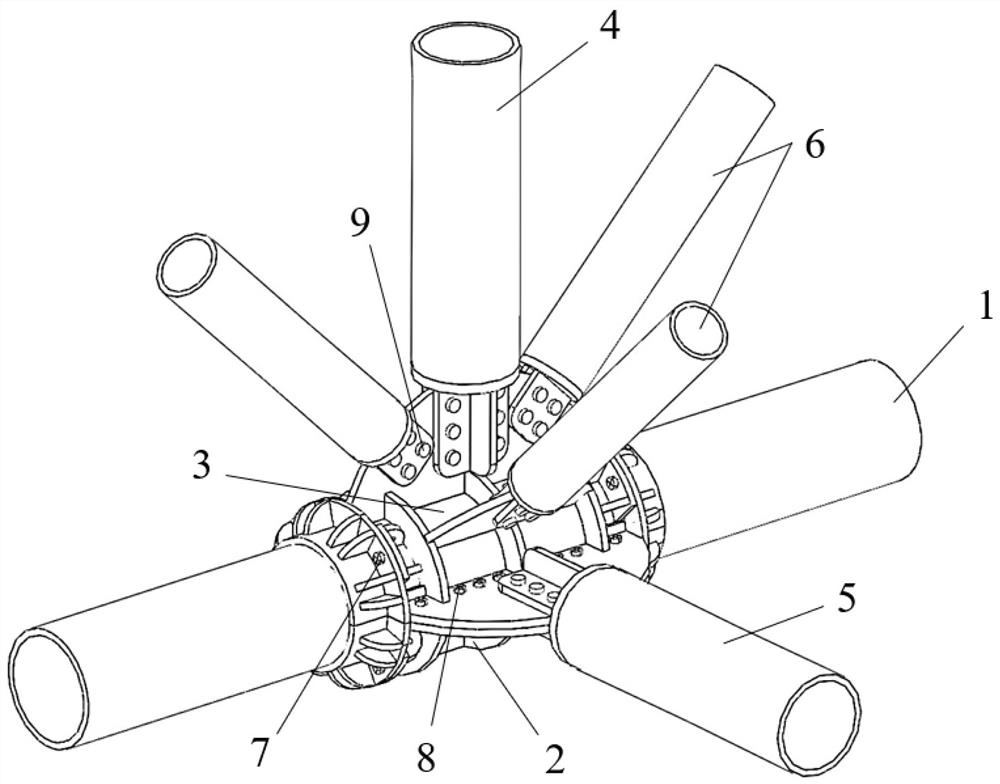

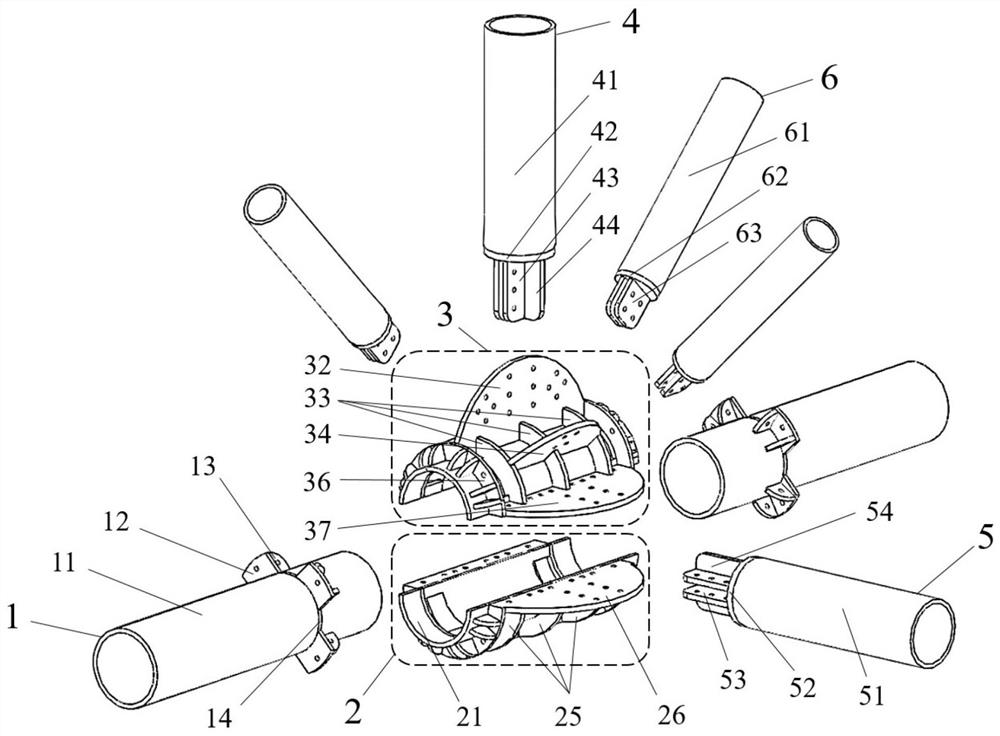

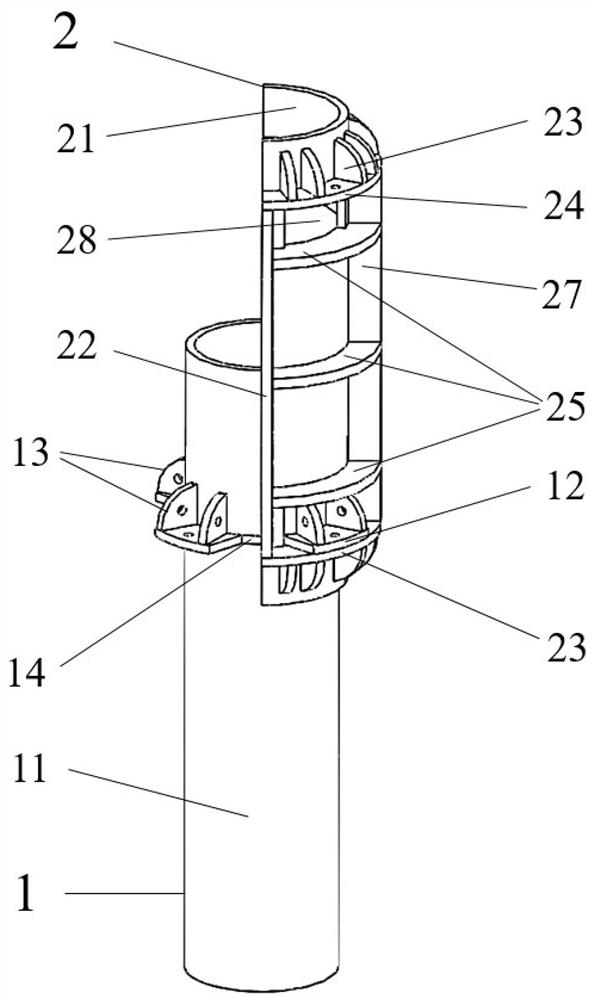

[0045] see Figure 1-Figure 16 , the present invention provides the following technical solutions: an assembled outer sleeve staggered flange intersecting node, including a lower outer sleeve 2 and an upper outer sleeve 3, and the two ends of the lower outer sleeve 2 and the upper outer sleeve 3 are plugged The main chord 1, the lower outer sleeve 2 and the lower chord 5 installed on the side of the upper outer sleeve 3, and the vertical rod 4 and the diagonal rod 6 arranged on the side surface of the upper outer sleeve 3, the main chord 1 and the lower Between the outer sleeves 2 and between the main chord 1 and the upper outer sleeve 3 are all fixed by the first connection assembly, and the connection plate high-strength bolts 8 are fixedly installed between the lower outer sleeve 2 and the upper outer sleeve 3, and the vertical The rod 4 and the upper outer sleeve 3 are fixed by the second connection assembly, the lower chord 5 is fixed on the sides of the lower outer sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com