Double-fluid atomization spray ring

A two-fluid nozzle and atomizing spray technology, which is applied in the direction of liquid spraying devices, spraying devices, spraying devices, etc., can solve the problems of insufficient spraying distance, difficulty in adapting to large-scale industrial use scenarios, poor spray uniformity and coverage, and achieve Reduce clogging, accurate and convenient spray coverage and uniformity of spray, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-9 The application is described in further detail.

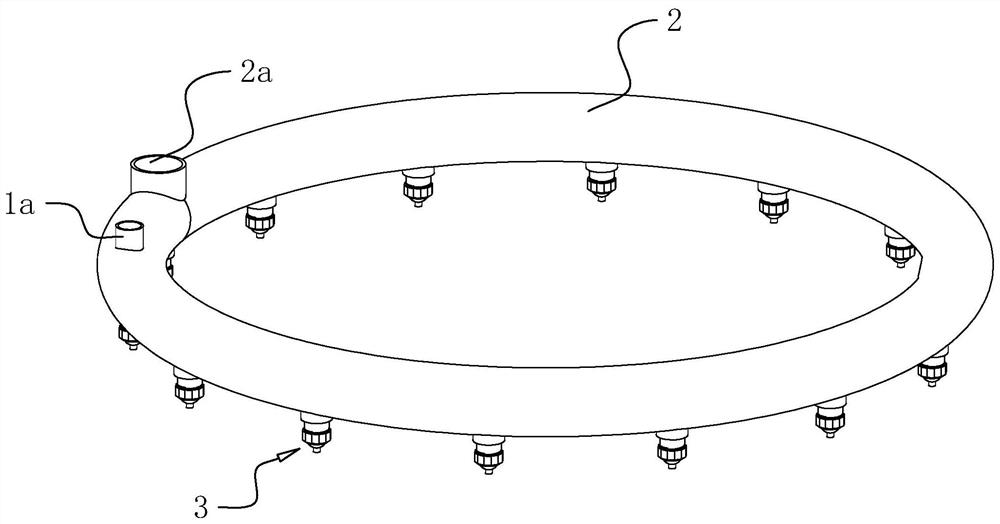

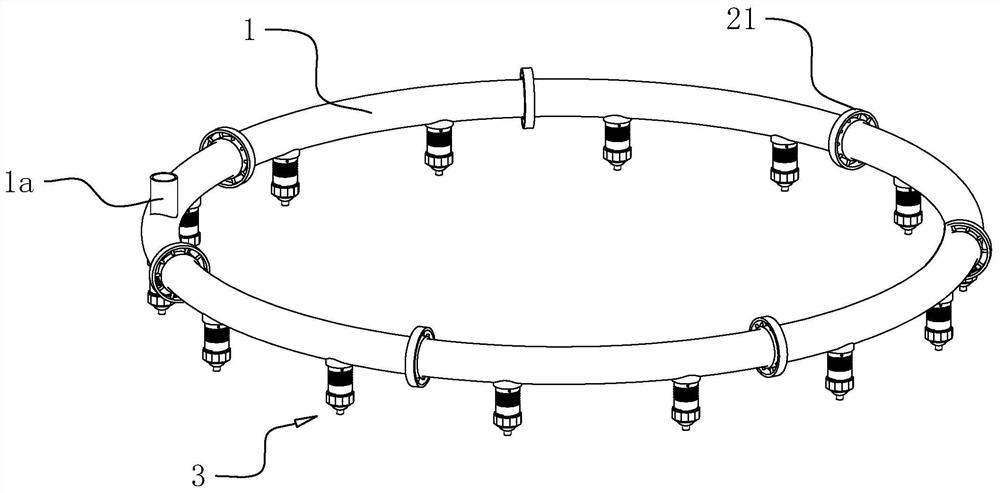

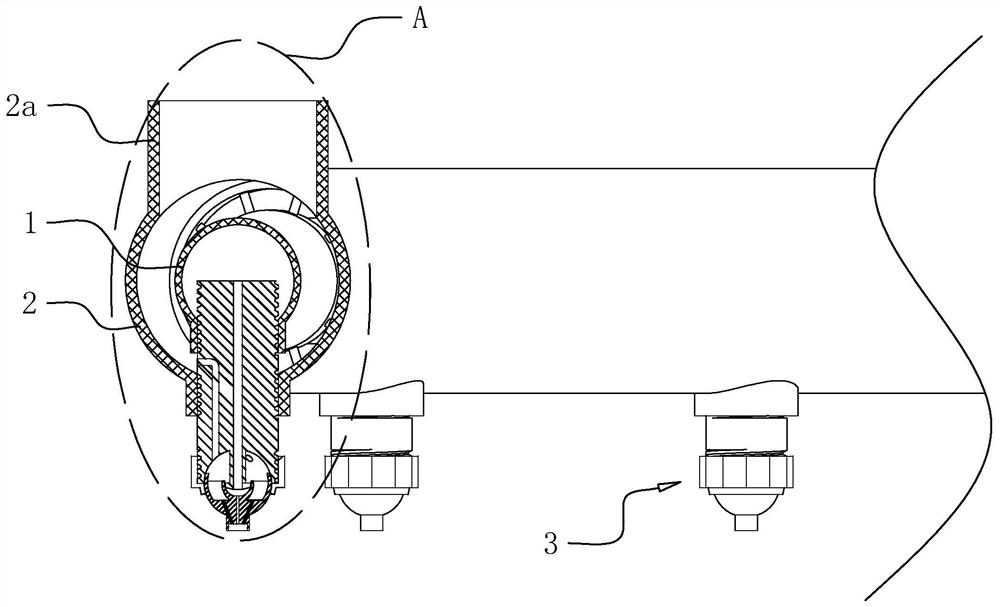

[0044] refer to figure 1 and figure 2 , is a two-fluid atomizing spray ring disclosed in the embodiment of this application. The two-fluid atomizing spray ring includes a ring-shaped inner flow channel 1, the inner flow channel 1 itself is closed and connected end to end, and the inner flow channel 1 is connected with a liquid inlet pipe 1a; and coaxially sleeved outside the inner flow channel 1 The outer runner 2 on the wall is also closed and connected end to end, and the outer runner 2 is connected with an air intake pipe 2a; the inner runner 1 and the outer runner 2 are fixedly connected by a plurality of fixing rings 21, and the fixing rings 21 There is a gap for the passage of compressed gas; the liquid inlet pipe 1a also runs through the outer flow channel 2 and is welded with the outer flow channel 2 in a sealed manner.

[0045] refer to image 3 and Figure 4At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com